Engineering Services to improve productivity

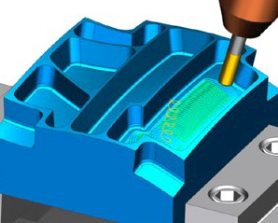

Programming services are just some of the contract services available from Seco Tools Engineering Services. Get details and sign up.Propel your production toward success with the right CAM programming for every job. Efficiency, optimized production time and optimal part quality all begin with the right engineering. In fact, CAM programming can save up to 50% of your machine cycle time – if you get it right.

And your jobs aren’t complete if they don’t pass inspection, so "Done" is not enough: You need parts that are done right.

To find the solutions that optimize your efficiency, process security and capacity, you need every advantage. Engineering services from Seco help you eliminate problems and boost success.

Increase production speed

Shorten cycle times

Boost machine utilization

Heighten workpiece precision

Improve material consistency

Eliminate waste and scrap

Reduce energy consumption

As your high-tech partner, we help you define the machining process and its CAM programming for greater productivity. We build our process around the application and feature-based methods that give you the best cycle times. At every step, we help you define your unique competitive advantages, and navigate the path to efficiency and better results.

Our customers compete in many industries, including aerospace, medical and general engineering, but all of them want to reduce production cost and save energy while they produce medium-difficulty and complex components.

They typically connect with our Engineering Services for these needs:

1. Productivity improvement

2. Cost savings

3. Cycle time reduction

4. Application of best practices

5. Capacity Issues (staffing and software)

To drive efficiency and productivity on our customers’ shop floors, we optimize their operations with CAM methodology that combines knowledge of applications and materials.

We always investigate best practices, and analyze ways to optimize processes and reduce manufacturing waste.

Here's how to implement CAM programming services:

- Basic CAM programming requirements for the component to be machined are provided by the customer.

- Deliverables are identified by Seco and a statement of work is approved by the customer.

- Customer input is reviewed by Seco.

- Experienced Seco CAM programmers with a strong understanding of machining processes and compatible CAM methods execute the project.

- Customer reviews progress and Seco responds to their feedback.

To access our online brochure and discover how our engineering services can help meet the challenges of Industry 4.0, click this link

We always focus on quality, process security, and increased efficiency and productivity – for your competitive advantages. For more information about Seco Engineering Services, contact us!

Inline Content - Sugar Form

Sugar Form url - https://info.secotools.com/acton/fs/blocks/showLandingPage/a/45194/p/p-001b/t/page/fm/0

Frame height - 380 px