6 TIPS FOR HIGH PERFORAMNCE MACHINING

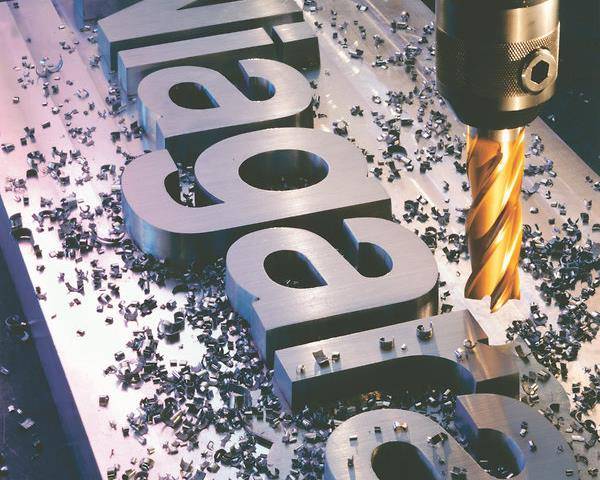

Check out these 6 tips for high perforamance machining.1. UNDERSTANDING THE NEED FOR INCREASED CUTTING PRESSURE

As a rule of thumb, a minimum of 20% of the diameter of the tool should be utilized. If the part and/or machine configuration does not allow for this large of a step-over, then the recommended catalog feed rate should be doubled to increase cutting pressure. Failure to “load” the tool may cause premature wear and a loss in productivity.

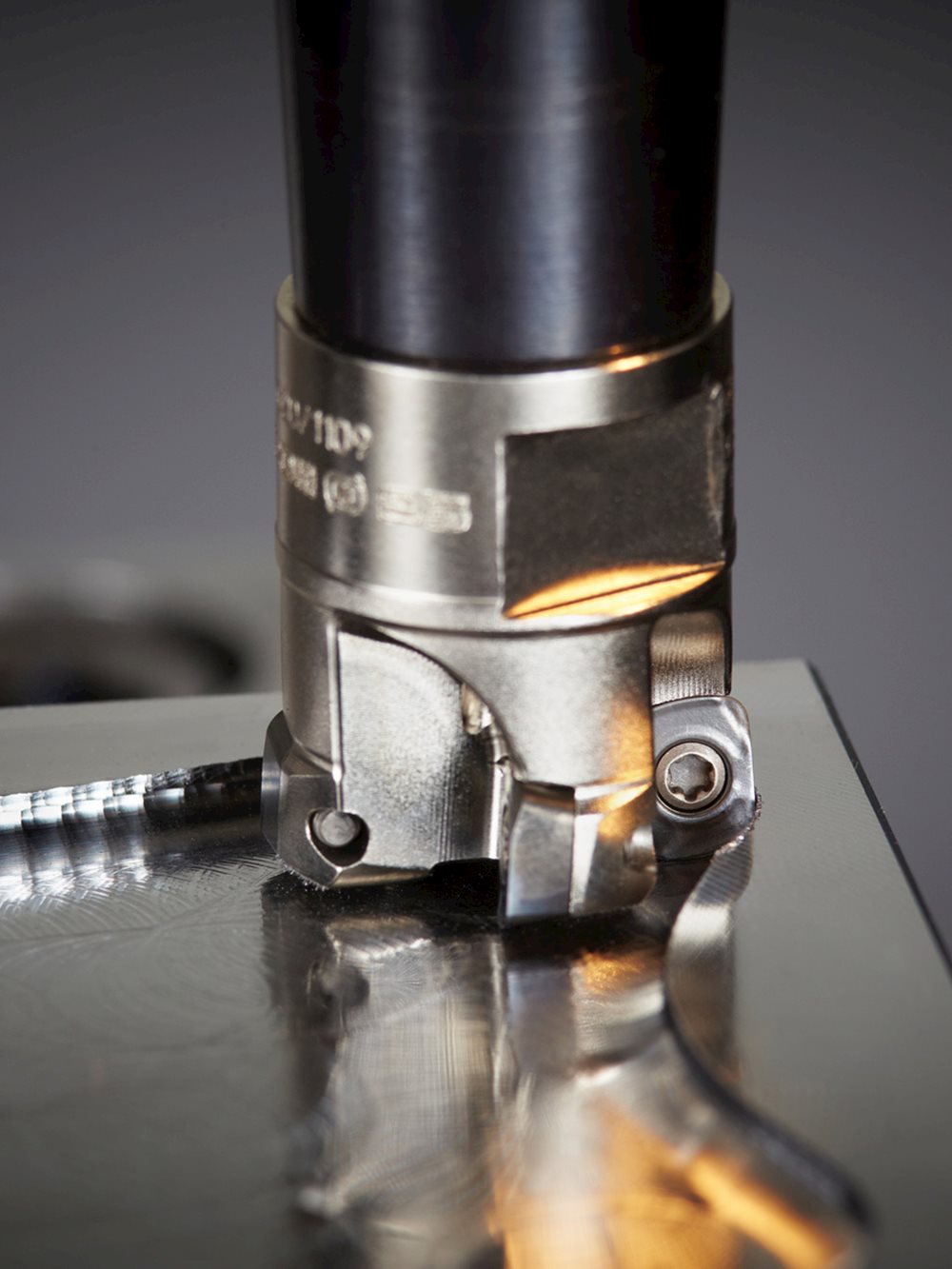

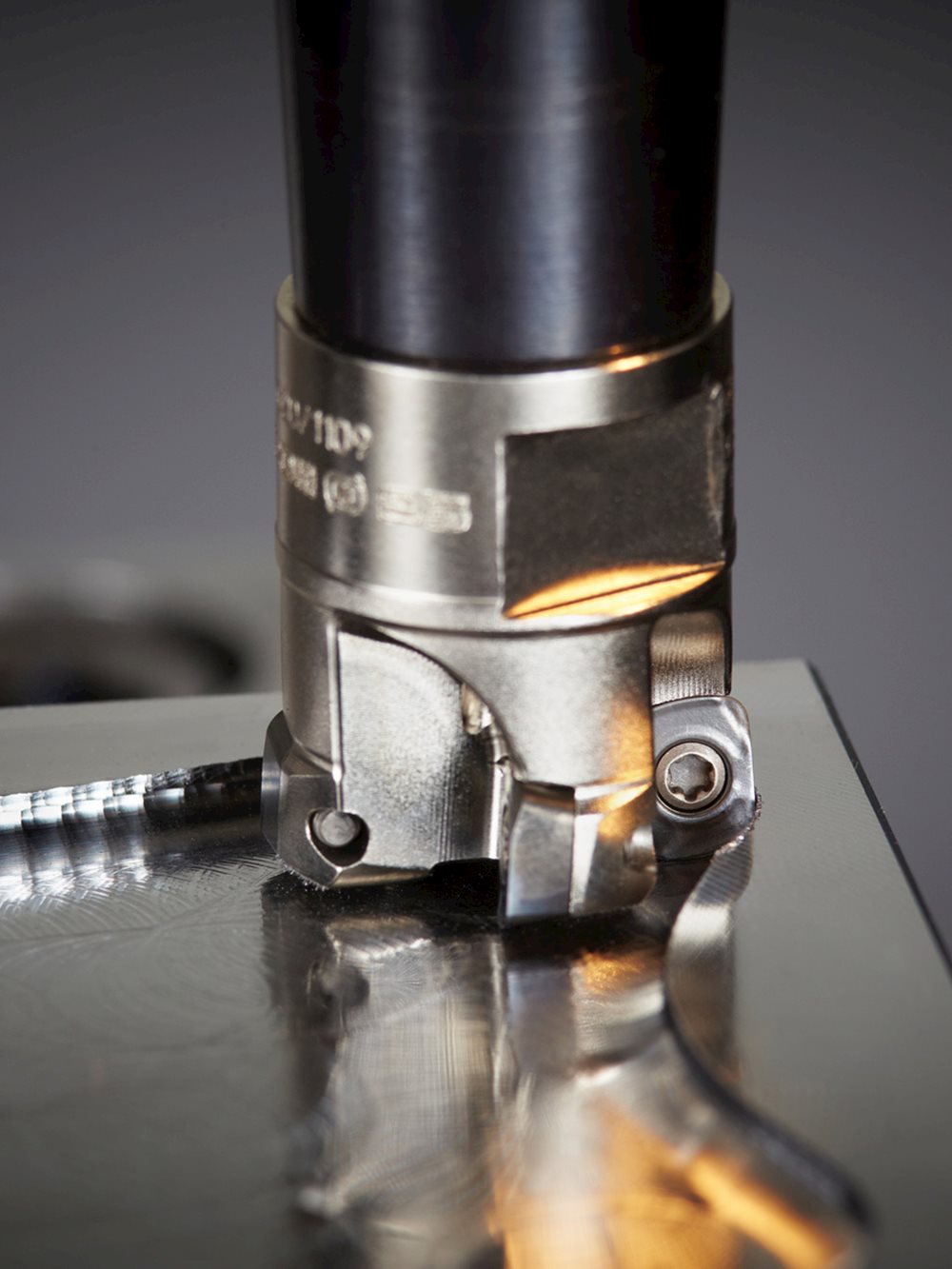

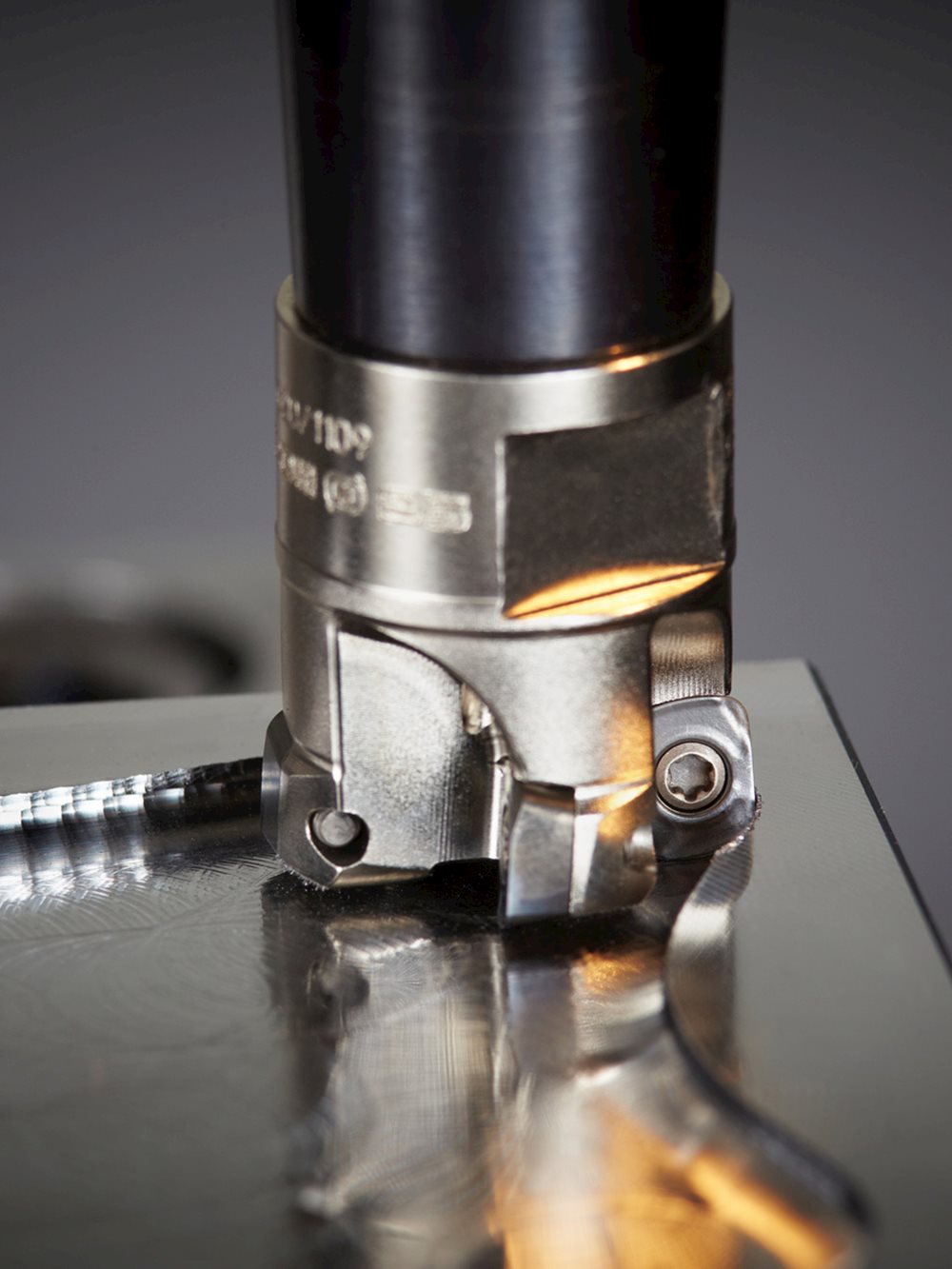

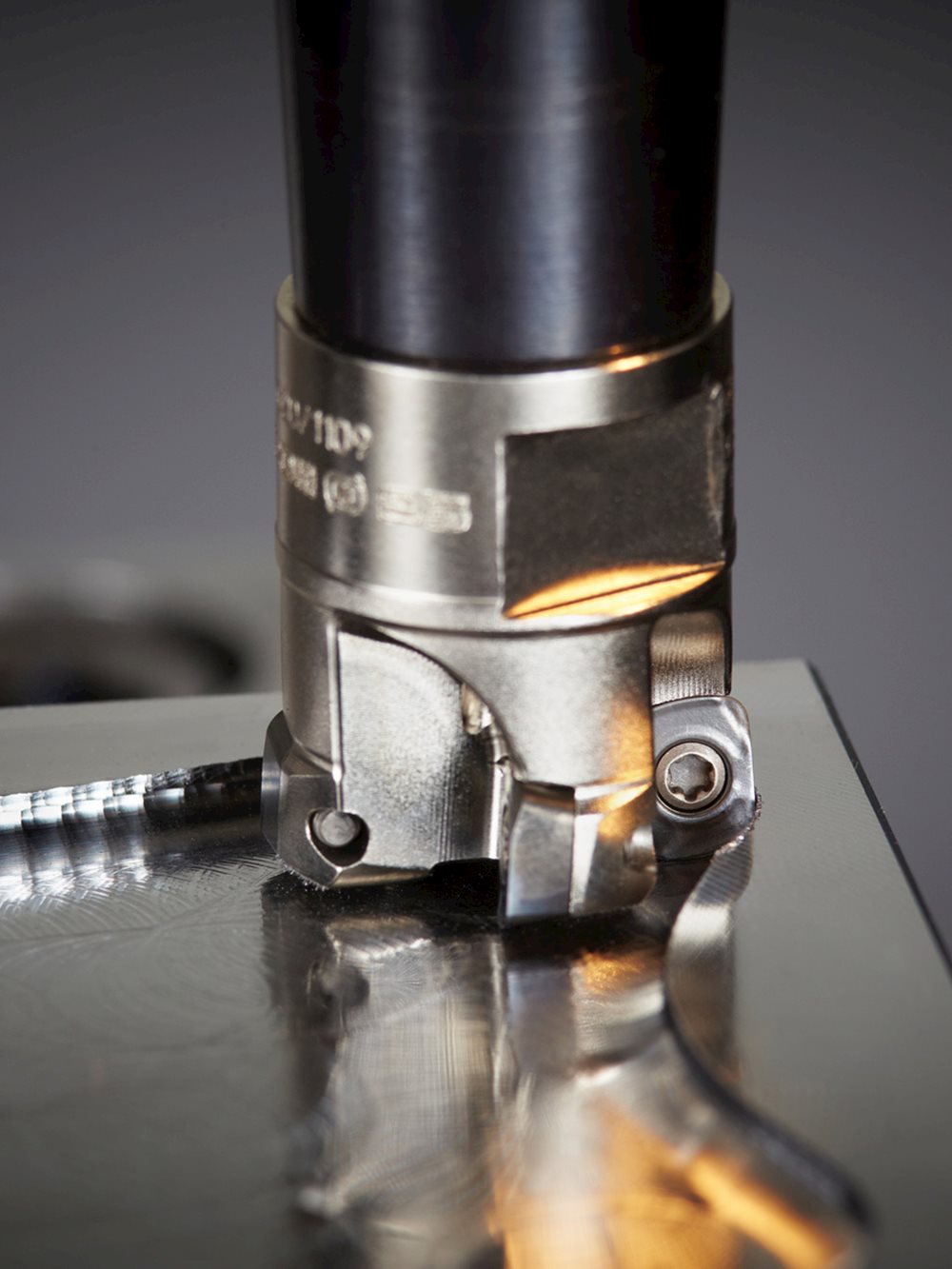

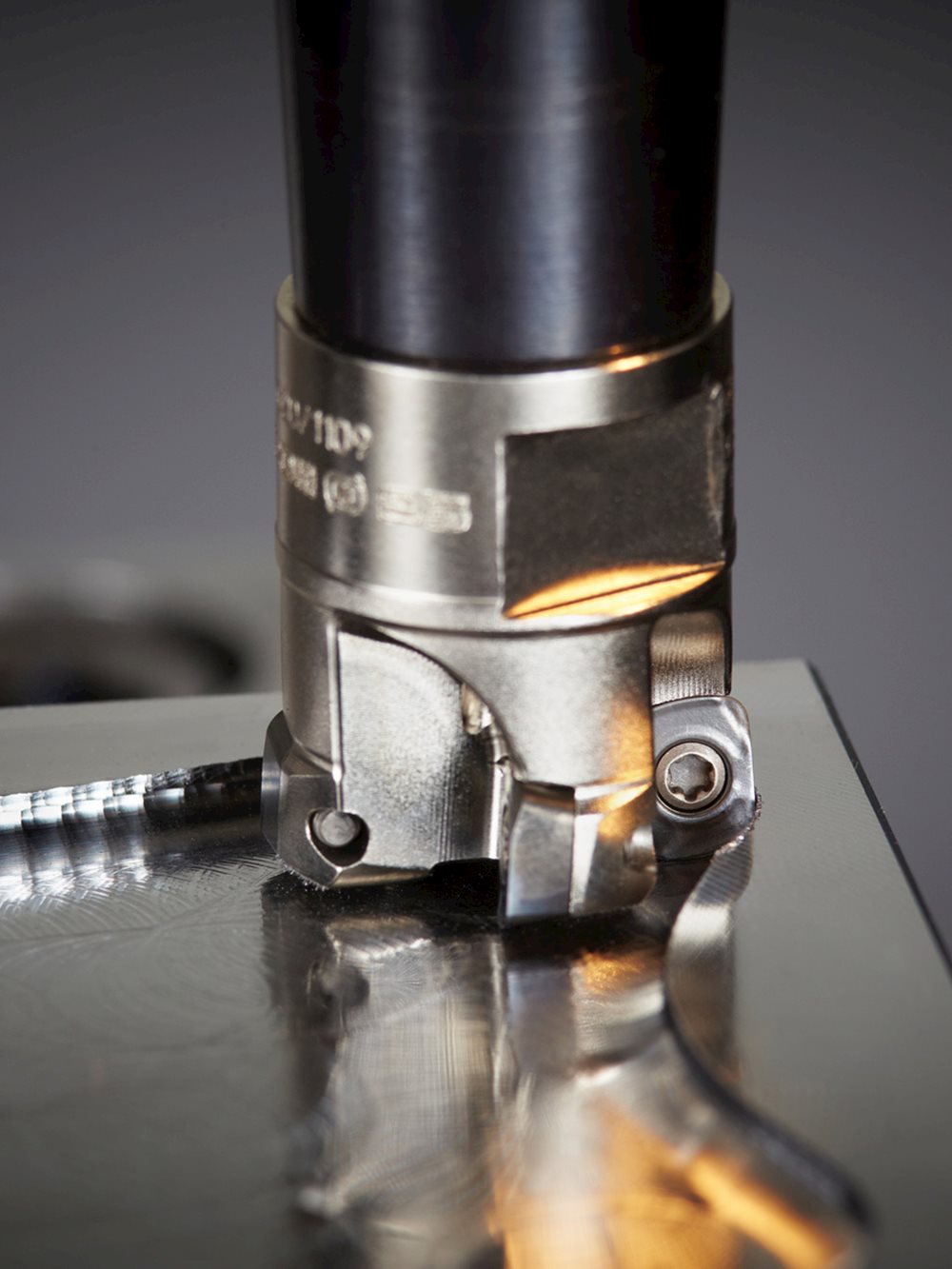

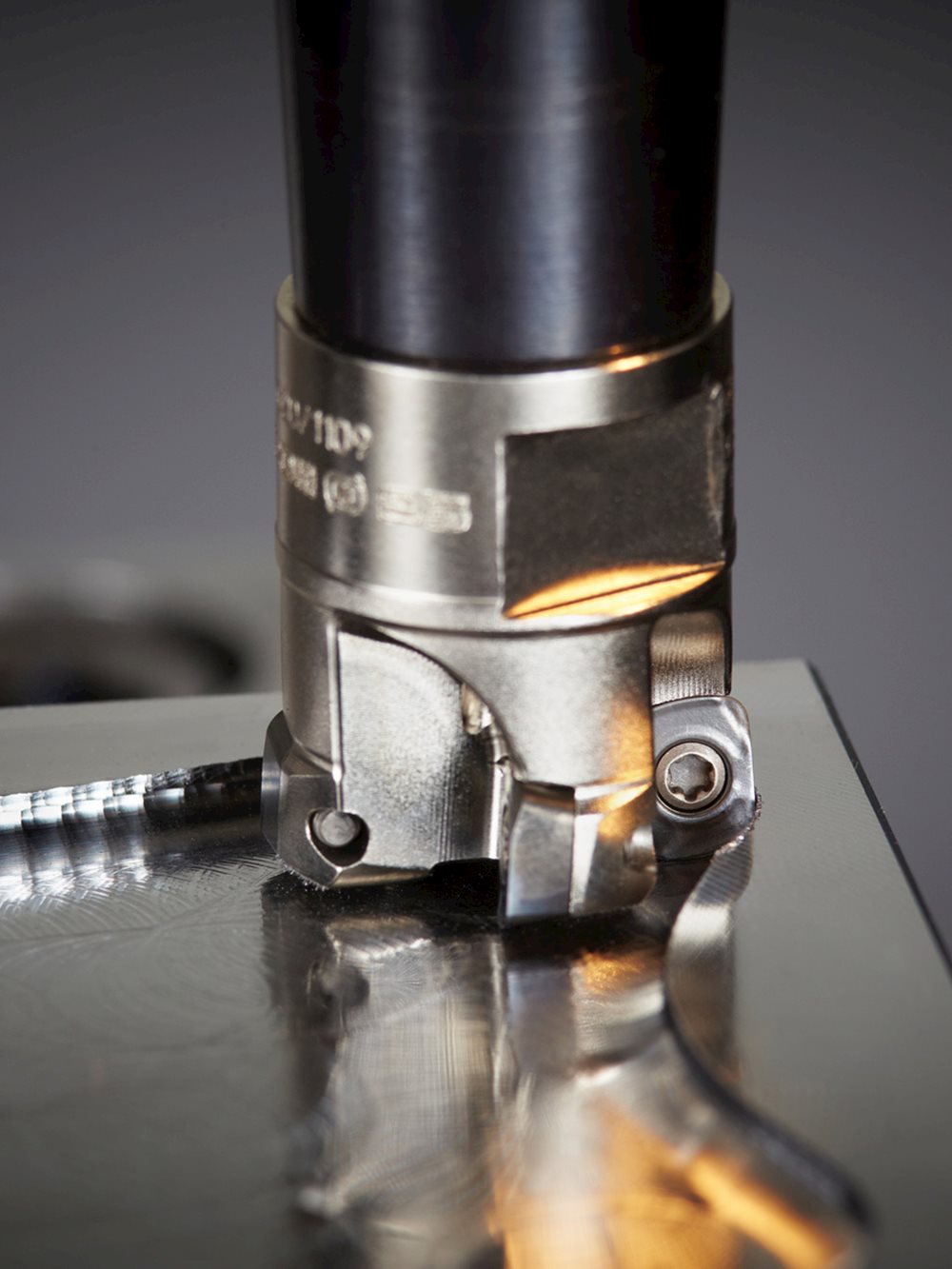

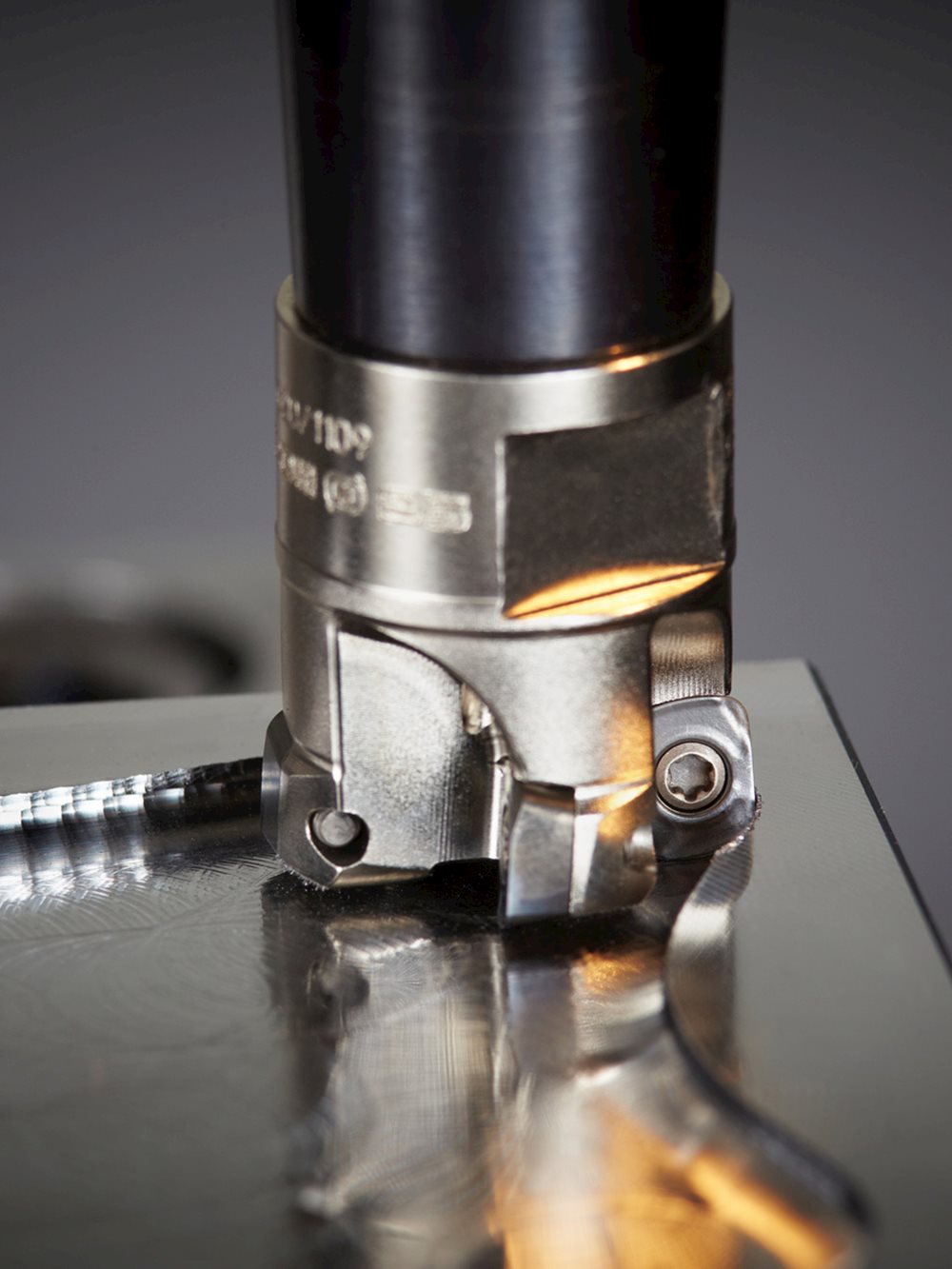

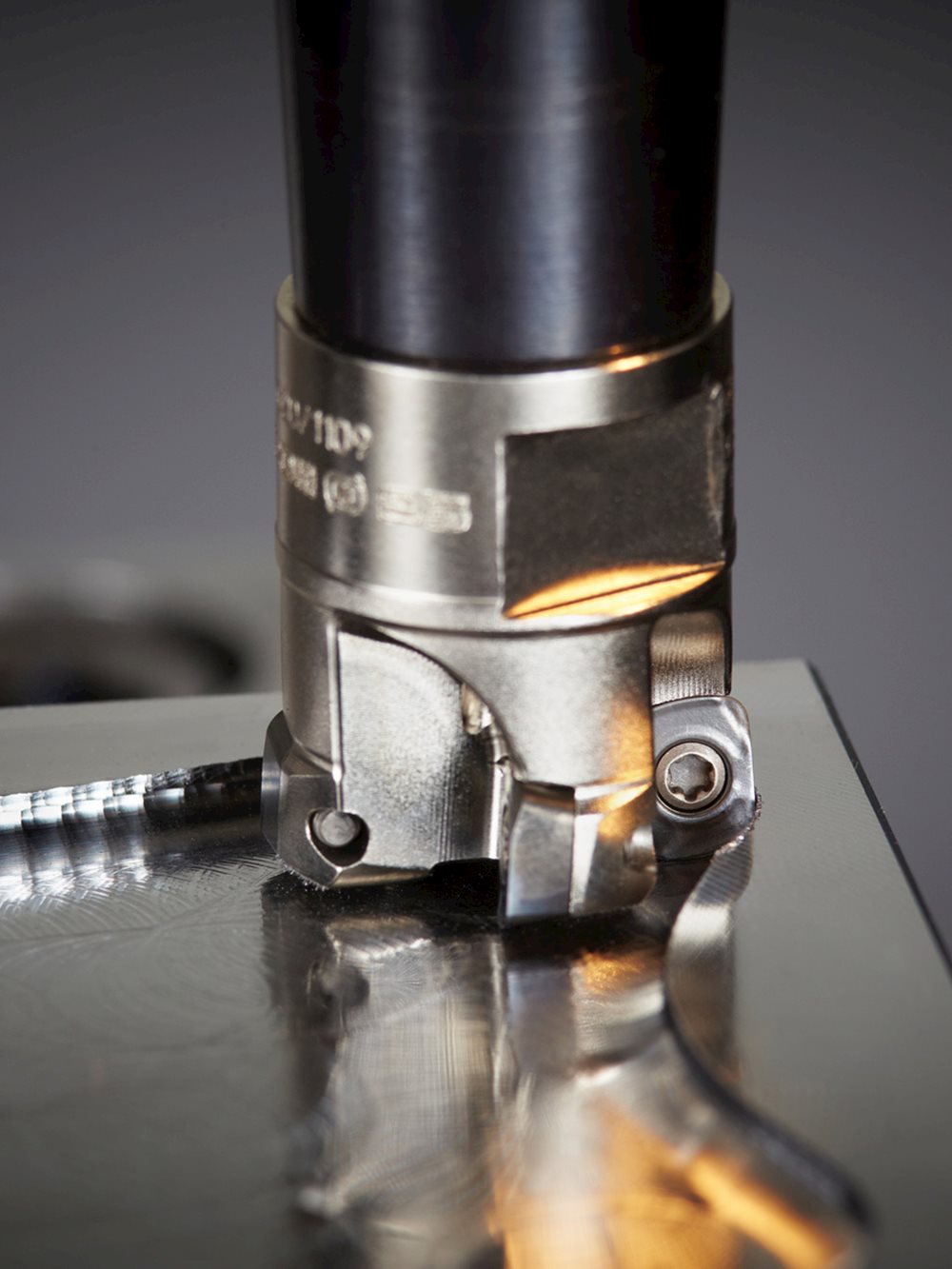

2. USE STRONG, SECURE TOOL HOLDERS & FIXTURING

Utilizing an anti-pull-out system is the first choice when high-performance milling is applied. Sidelock holders, milling chucks, and Shrinkfit holders with anti-pull-out systems will help ensure that the tools are secure and provide optimal run-out of less than 0.0004”. Some high-precision collet systems and heavy-duty reinforced hydraulic chucks are a second option. However, the pull-out cannot be forgotten. Rigid fixturing and clamping will help ensure that the workpiece stays fastened to the machining table.

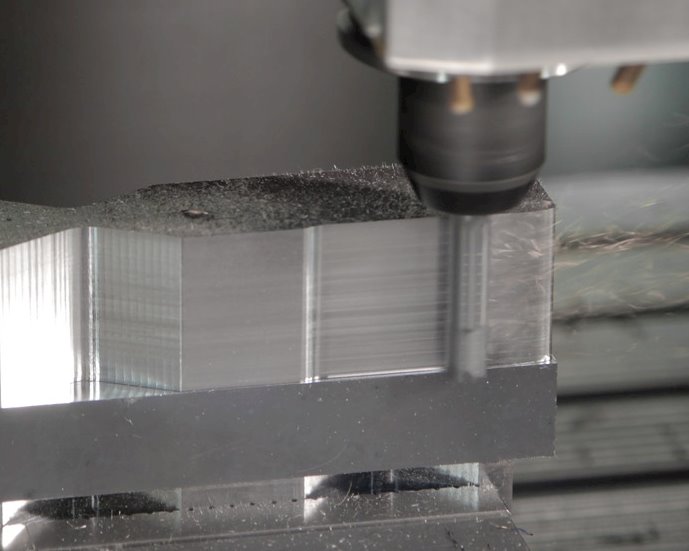

3. LIMITING FACTORS OF MACHINE TOOLS

Knowing machine tool limitations and horsepower consumption rates prior to implementing HPM strategies is crucial for success. These methods consume higher levels of horsepower and torque compared to standard milling strategies, this can push machine tools past their limits causing catastrophic failures. Using greater than a ½” diameter end mill in a CAT40 or similar size taper machine tool while utilizing HPM strategies could be problematic. Knowing your machine’s limit is always the best option.

4. NOT ALL STAINLESS STEELS ARE CREATED EQUAL

To ensure optimal success, careful consideration must be taken when machining common pH hardened stainless steels such as 13-8, 15-5, and 17-4. When heat-treated to a range of 32-42 HRc, these materials have a machining characteristic like common tool steel. The ST430.2 is designed for steel machining applications and may be a better option than the ST440.2 which is the first choice tool for stainless steel applications. Utilizing the recommended cutting parameters for the ST440.2 while using the ST430.2, is a safe common practice.

5. VERSATILE STABILIZER 2.0

If you wanted to choose one Stabilizer 2.0 series as an all-around tool for machining both steel and stainless steels, the ST440.2 series is the answer. Feed rates in steel are lower than the ST430.2 series due to reduced chip spacing (higher helix angle = less chip spacing). On average, the fpt of the ST440.2 series is 25% of the max feed rate in steel compared to the ST430.2 series. Example: fpt in 4140 for a 1.00” OD ST430.2 is 0.005”, fpt for a 1.00” OD ST440.2 will only be 0.00375”.

6. RECOMMENDED CUTTING PARAMETERS

Through meticulous research and years of first-hand experience, we have developed specific recommended cutting parameters. Cutting data is optimized for each tool’s design, specifications, and material groups. These configurations should always be used as a starting point and then modified from there depending on the application.

Related content

Stabilizer 2.0 range overview

High Performance Optimized Roughing in 17 4 PH Stainless Steel Dry

Niagara Cutter High Feed Machining Product Introduction

Milling

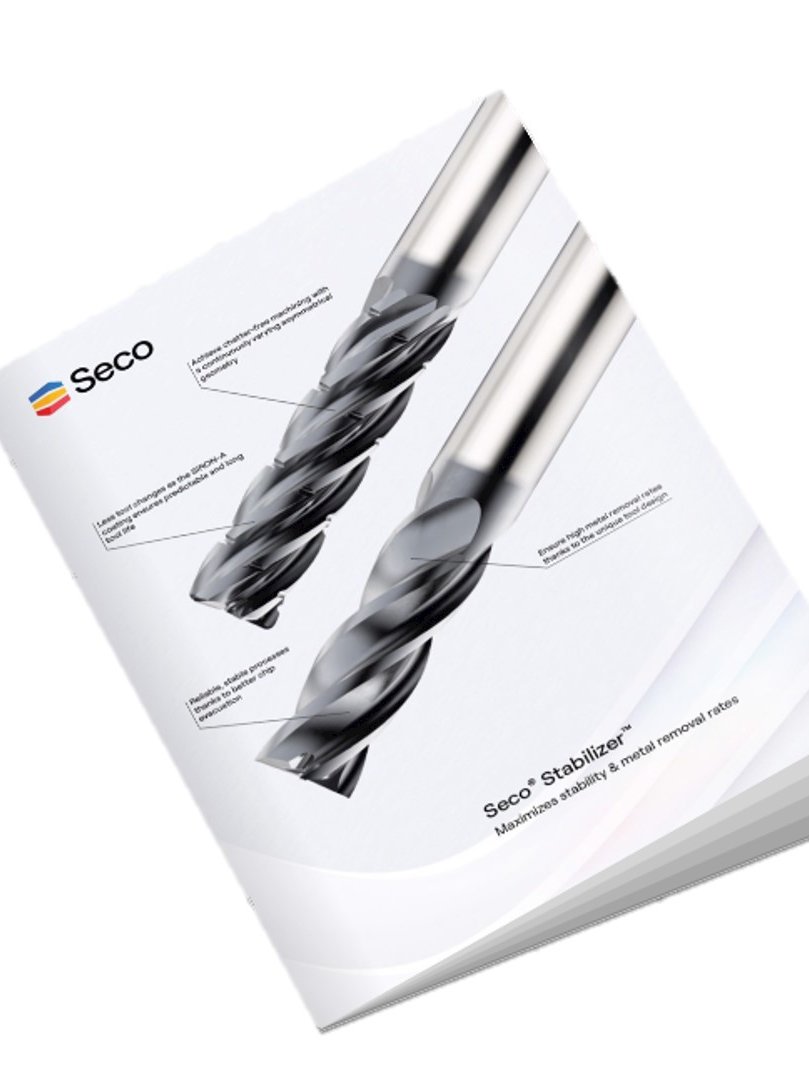

Factsheet - Seco® Stabilizer™

ABOUT NIAGARA CUTTER

STR440.2 - High Performance - Square and Ball - Superalloys - 4 Flutes

STR430.2 - High Performance - Square and Ball - Steel - 4 Flutes

Video: Duratomic: Top performance

Video: Niagara Cutter Stabilizer 2.0 Product Introduction

Seco Stabilizer Series: Unmatched Metal Removal

Machining Navigator / Product Catalog Milling

Niagara Cutter Multi Flute - Elite Series

Optimized Roughing 17-4 PH Stainless Steel Dry

Niagara Cutter's SN200R, SN400R and SN500R

High Performance Optimized Roughing with Stabilizer 2.0

Mold & Die End Mill Expansion Introduction

Seco Stabilizer ST5541 permorming Dynamic Milling

Seco Stabilizer ST5541 Side Milling and Ramping machining demo | Seco Tools

Seco Stabilizer ST5541 Slot Milling demo | Seco Tools

Suggest