How to Select the Proper Milling Grade

Selecting the appropriate indexable milling insert for your application does not have to be a complicated process. Despite a variety of grade and geometry combinations and any number of application scenarios, optimized milling operations can be obtained for all material groups to improve removal rates, tool life and surface finishes.

The “grade” of a milling insert is the combination of its base material (usually tungsten carbide), coating and any other post- and pre-treatments. To enhance performance, Seco uses either a chemical vapor deposition (CVD) or physical vapor deposition (PVD) process to coat the carbide substrate of its milling inserts.

CVD bonds a coating to a tool by injecting a combination of volatile gas and metal or ceramic vapor into a heated vacuum chamber. CVD produces a layer that is 7 µm or thicker and provides an effective heat barrier for increased cutting speeds. CVD’s thick coating capacity will not allow it to be applied to extremely sharp cutting edges, and it is prone to cracking and breaking in comparison to PVD coatings.

PVD layers coatings by using an electrical charge to vaporize solid metal in a vacuum. PVD coatings can be up to 4 or 5 µm thick and can be applied to all geometries but are most beneficial for sharp geometries.. PVD coatings are tougher due to process-related compression stresses with smooth surfaces that generate less friction for operation at lower cutting speeds.

As an alternative to coated tools, uncoated milling inserts are well suited to machining non-ferrous materials such as aluminum alloys.

Grades tend toward “toughness” or “hardness.” Tougher grades are more resistant to impact and can withstand the heavier mechanical loads of interrupted cuts, vibrations and processing heterogeneous materials without chipping. Hard grades show less abrasive wear, and in combination with CVD coating provide high heat resistance for high-speed uninterrupted cutting. Hard grades are more brittle, however, with a higher tendency toward a wear mode of chipping or thermal cracks.

Choosing and using the appropriate grade for an application is essential to balance tool life, performance and productivity. For sustainable, cost-effective manufacturing, tool life must be maximized and the machining process must be as efficient as possible. Undue tool wear, scrapped parts, downtime and excess machining all increase costs and reduce profitability. In terms of insert grades, shops should optimize to the most wear-resistant grade that provides the least amount of chipping while providing predictable wear pattern and development.

Workpiece material is always the first element to consider in grade selection. Non-ferrous metals, super alloys, steel and other materials will directly influence grade choice. Workpiece size and shape are also considerations. For example, larger workpieces, in many cases, require bigger cutters and longer in-cut time. The combination of increased cutter size and in-cut time can lead to higher temperatures in the cutting zone. Those conditions would suggest a tendency to use CVD grades as opposed to PVD on large components.

Machining conditions are the next factors to consider and involve answering some key questions. Are the conditions stable or unstable? Is the milling continuous or interrupted? And, has the surface been pre-machined or is it rough skin?

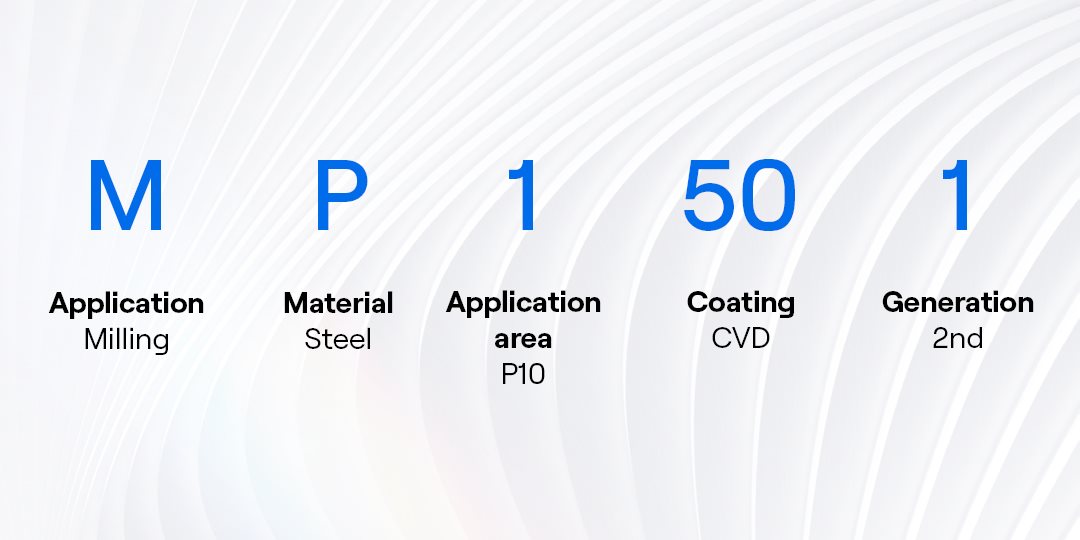

A shop’s overall tooling strategy also plays a role. Some grades are suited to machining the wide variety of materials and applications found in high-mix/low-volume production; however, their versatility comes at the expense of high performance for a particular process encountered in low-mix/high-volume manufacturing. As a result, shops must decide whether a more universal, all-round performance grade will cost-effectively meet their requirements, such as F40M, or whether they will need a number of more specific grades to perform well in specific recurring situations, such as MP1501 and MP2050.

An insert’s grade should not be considered apart from its geometry. The combination of grade and geometry can play a significant role on grade wear and performance. For example, a hard grade combined with a sharp, positive or unprotected geometry will easily chip and fracture during uninterrupted cuts or when encountering inclusions.

Seco provides five geometry categories ranging from E for easy cutting through M for medium and D indicating difficult machining conditions. Two intermediate ranges – ME and MD -- on the easy and difficult side of M, respectively, allow fine tuning of the operation after analyzing wear patterns and performance. Fully optimizing tool life and performance with your machining objective depends upon properly balancing insert grade and geometry.

Seco’s General Insert Milling Grade Chart helps shops find a general starting point for their applications with the appropriate combination of insert grade and geometry. Grades are arranged on the chart over workpiece material and ordered top to bottom by increasing toughness.

The harder, more wear-resistant grades are shown at the top of the chart. The chart also indicates a general starting point for geometries, progressing left to right from the most unprotected, positive geometry to heavily protected geometries for difficult cutting conditions. By analyzing results and wear patterns, processes can be optimized and fine-tuned by selecting a grade above or below the initial choice.

Selecting the proper insert grade will refine your milling operation for the proper balance of cost effectiveness, productivity and performance. Analyzing workpiece material, size and shape along with machining and surface conditions will present a solid starting point in grade selection. Fully optimizing the process with a more appropriate grade to the application and conditions can be accomplished by observing initial results and wear patterns and then adjusting accordingly.

Refer to our extensive overview of suitable milling grades

Seco’s digital catalogs and Seco Suggest provide online tooling recommendations for specific applications based on selected conditions. These comprehensive resources allow shops to find a starting point for new applications or research additional tooling options for ongoing projects. Additionally, shops can contact their local representative for detailed advice on selecting the right milling grade solution for their needs.

Inline Content - Survey

Current code - 5fce8e61489f3034e74adc64