Turning Grades – Understanding the Nomenclature

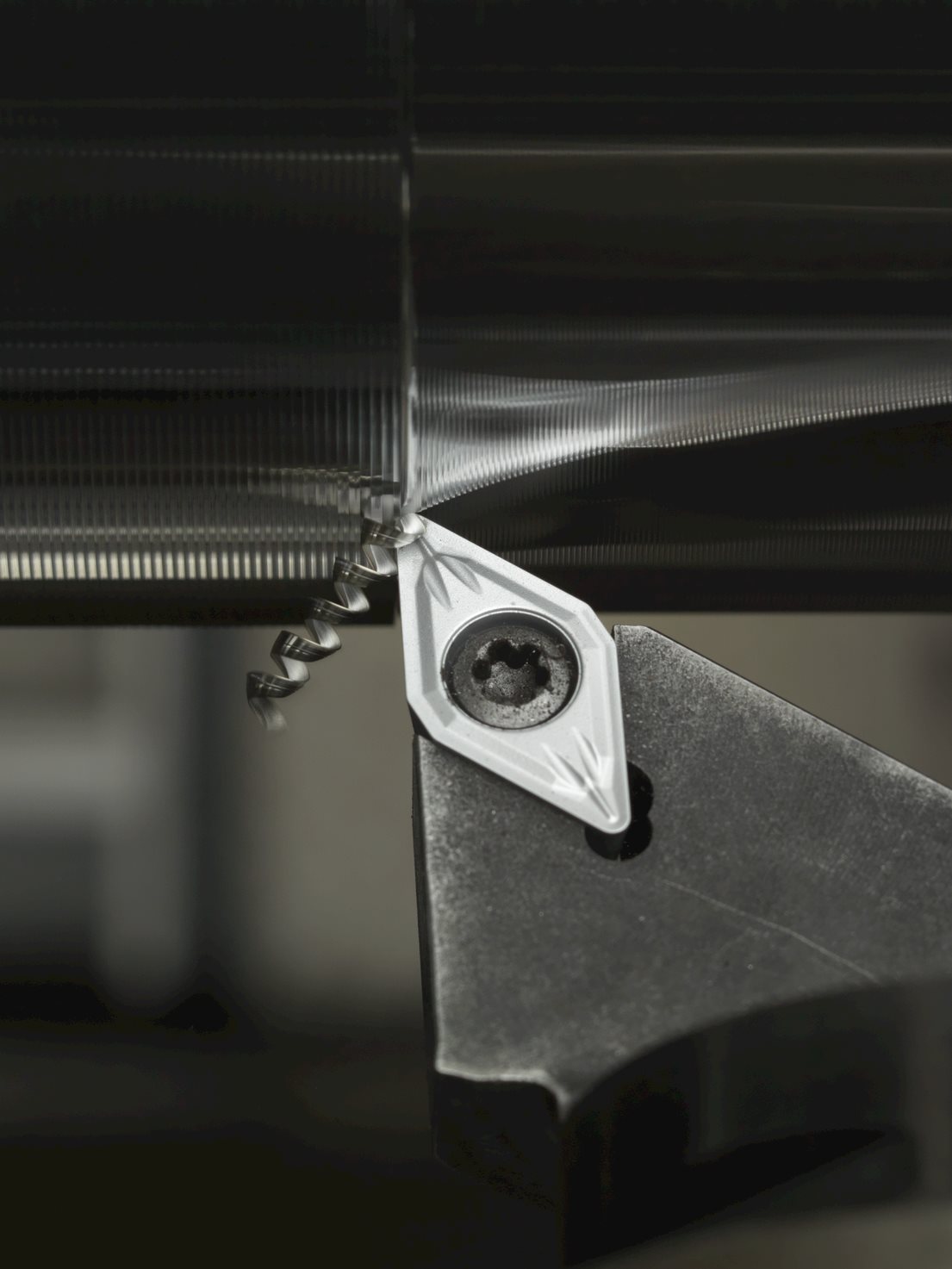

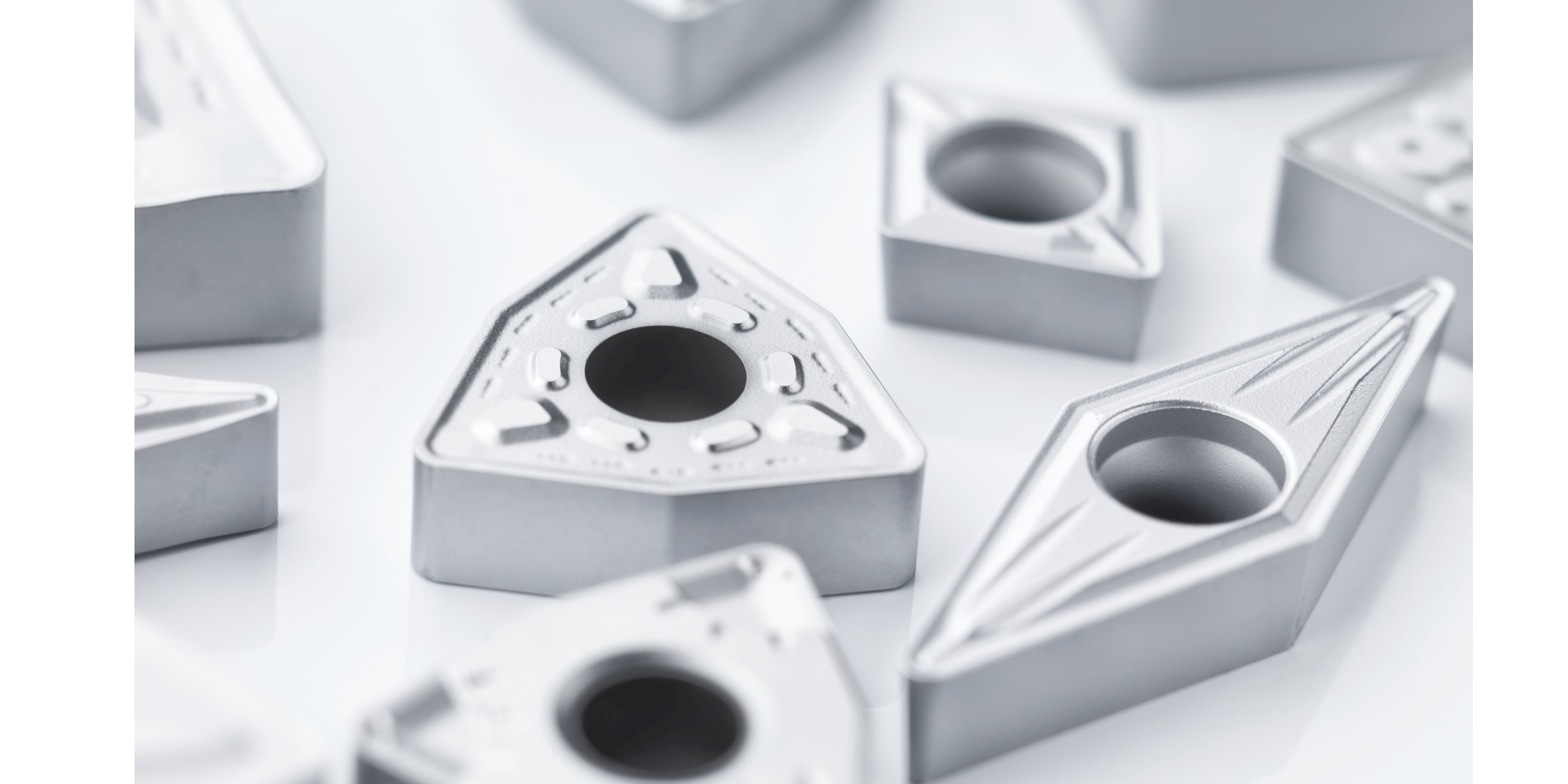

Whether you’re involved with general ISO turning, hard part turning, grooving, parting or threading, choosing the turning grade for the material and application can be essential to obtain your desired outcomes. Proper grade selection also provides opportunities to optimize machining efficiency, sustainability and productivity.

Seco turning grades follow a logical nomenclature that allow you to quickly understand grade characteristics and appropriate working ranges.

- All turning grades begin with the letter T to indicate they are “turning grades.” The same logic applies to across other Seco technologies. For example, the initial letters M and D indicate milling and drilling grades, respectively, and the letter C indicates deviating cutting materials for advanced machining, regardless of turning or milling applications.

- The second letter highlights the major material coverage and peak performance area of the grade. The letter P, for example, represents the steel material group.

- The third, fourth and fifth characters/numbers indicate the application range and are important when optimizing for wear pattern and performance in your application.

- The sixth character/number indicates a generation number.

Seco turning grades also include legacy and versatile grades that use elements of the high-performance nomenclature above to convey grade characteristics and suitable working ranges.

- Some Turning grades conform and begin with the letter T to indicate they are “turning grades.” TP25 and TP40 are two examples.

- There are also examples of legacy grades starting with the letter C, indicating an earlier deviating cutting material due to PVD coating. These legacy grades include but are not limited to CP200 and CP500.

- Trusted legacy grades of uncoated inserts, like 883 and 890, for Aerospace applications have had many decades of use, but grade nomenclatures have not been implemented.

Inline Content - Survey

Current code - 5fce8e61489f3034e74adc64

Related content

General Turning Inserts

Turning Inserts Poster

A Guide to Milling Grades, Materials and Solutions

General Turning - ISO

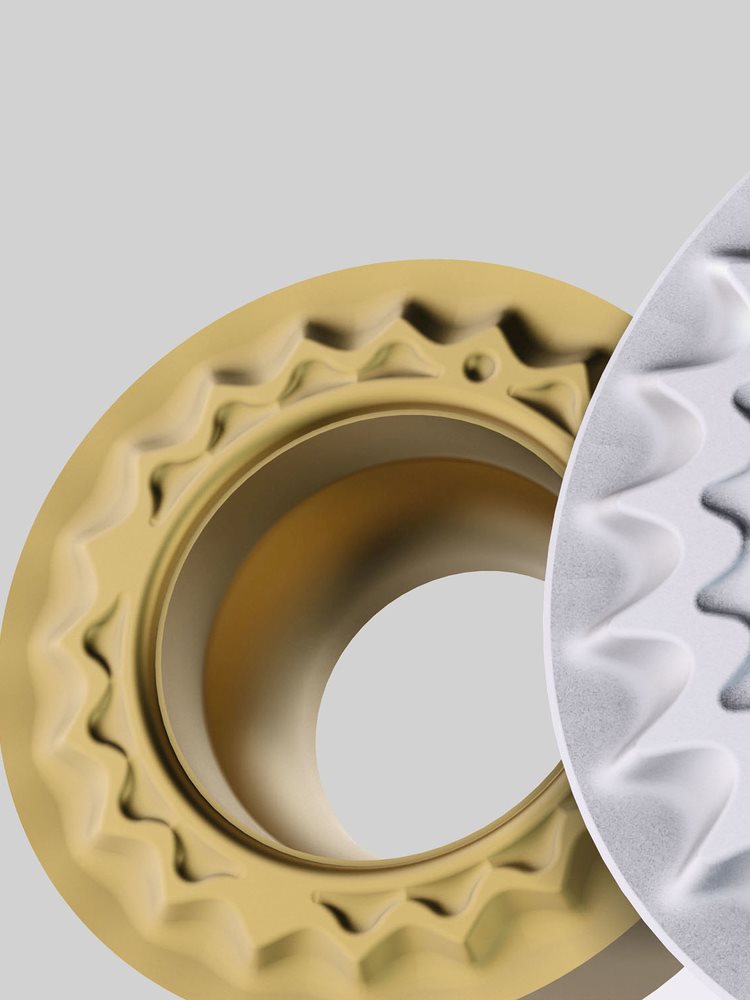

MF2 Chipbreaker on Round RCMT/RCGT Inserts