Seco Solid PCBN Wiper inserts for finish hard turning

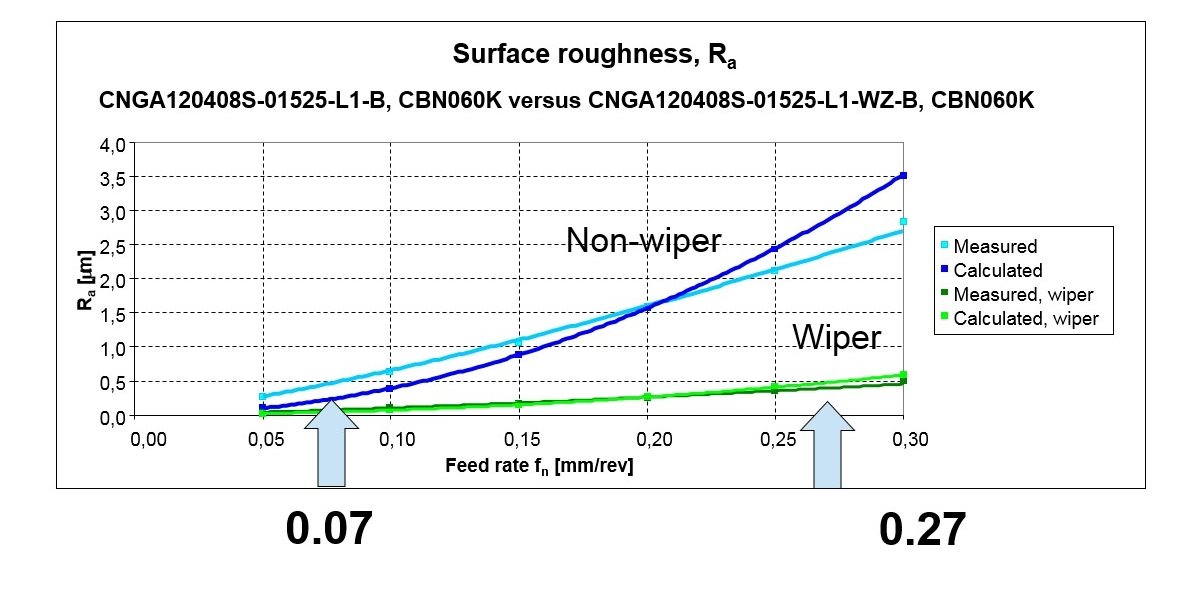

In turning with a single-point tool, the surface finish is determined by the feed rate and nose radius, as these are in a direct relationship to the profile height of the surface (Rmax). This means that the higher the feed, the rougher the surface generated by the edge of a given nose radius.

Standard insert geometry

The difference is in the nose radius. The nose on a wiper insert is actually a combination of radii instead of a single radius.

The large wiper radii enable the cutting edge to generate improved surface finish.

The Seco way, Solid TNGX11… inserts - 6 cutting edges with wiper.

The major advantage of solid PcBN over tipped PcBN inserts is the number of cutting edges available.

Due to the new pricing structure for 2018 the price level for solid TNGX11…wiper inserts are considerable reduced and are now an even more cost competitive alternative to brazed inserts.