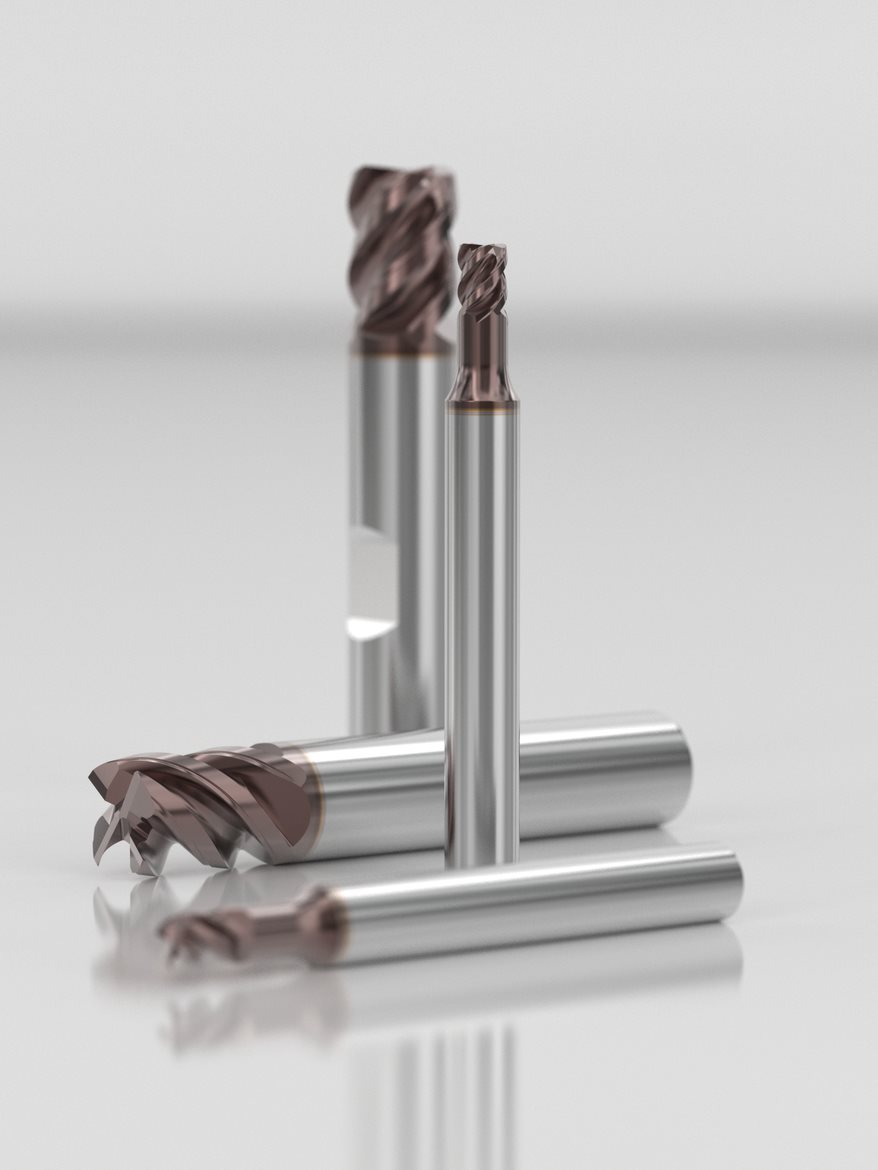

Comprehensive Range of Plug-and-Play Solid End Mills for Dental Labs

Cut anything from titanium dental implants to cubic zirconia dental crowns with a full range of plug-and-play solid carbide tools from one supplier.Discover the product range

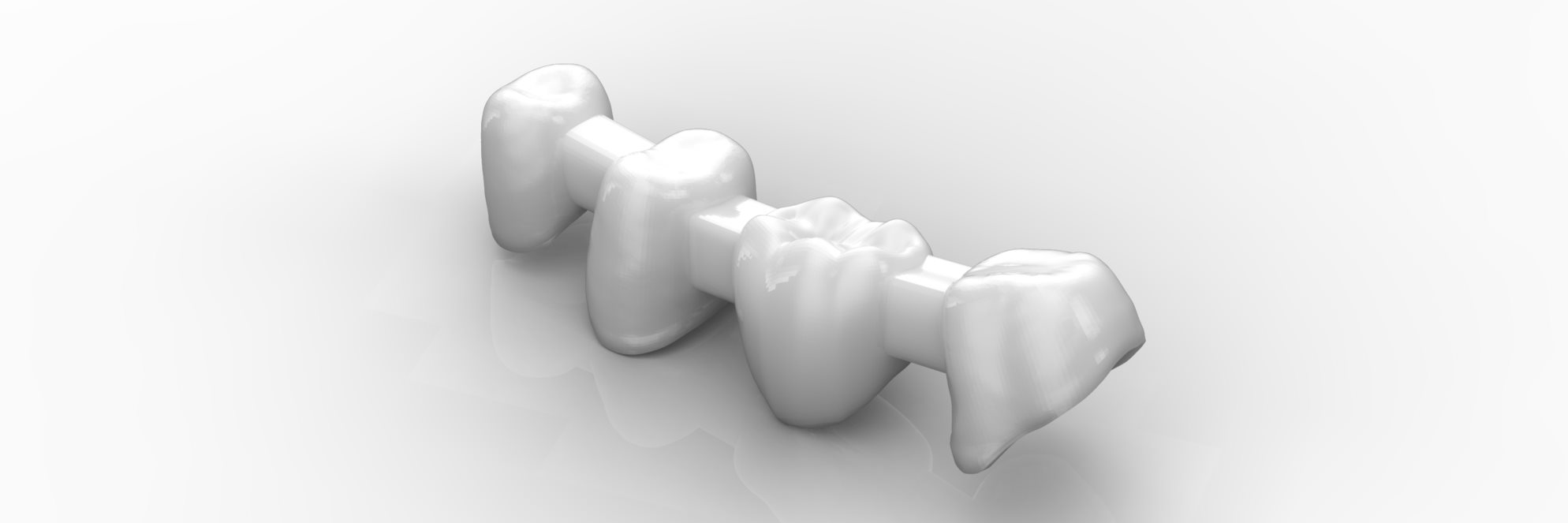

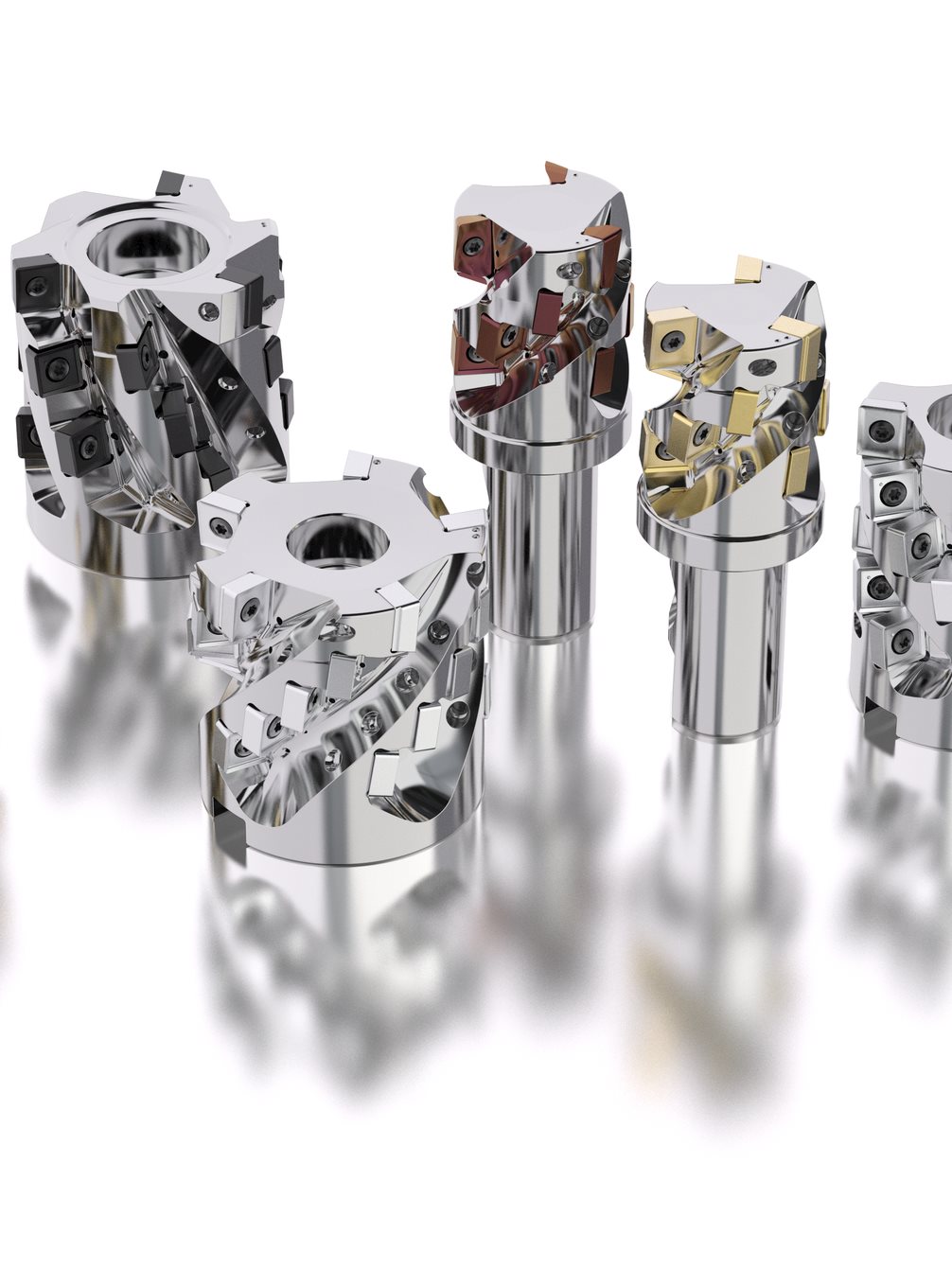

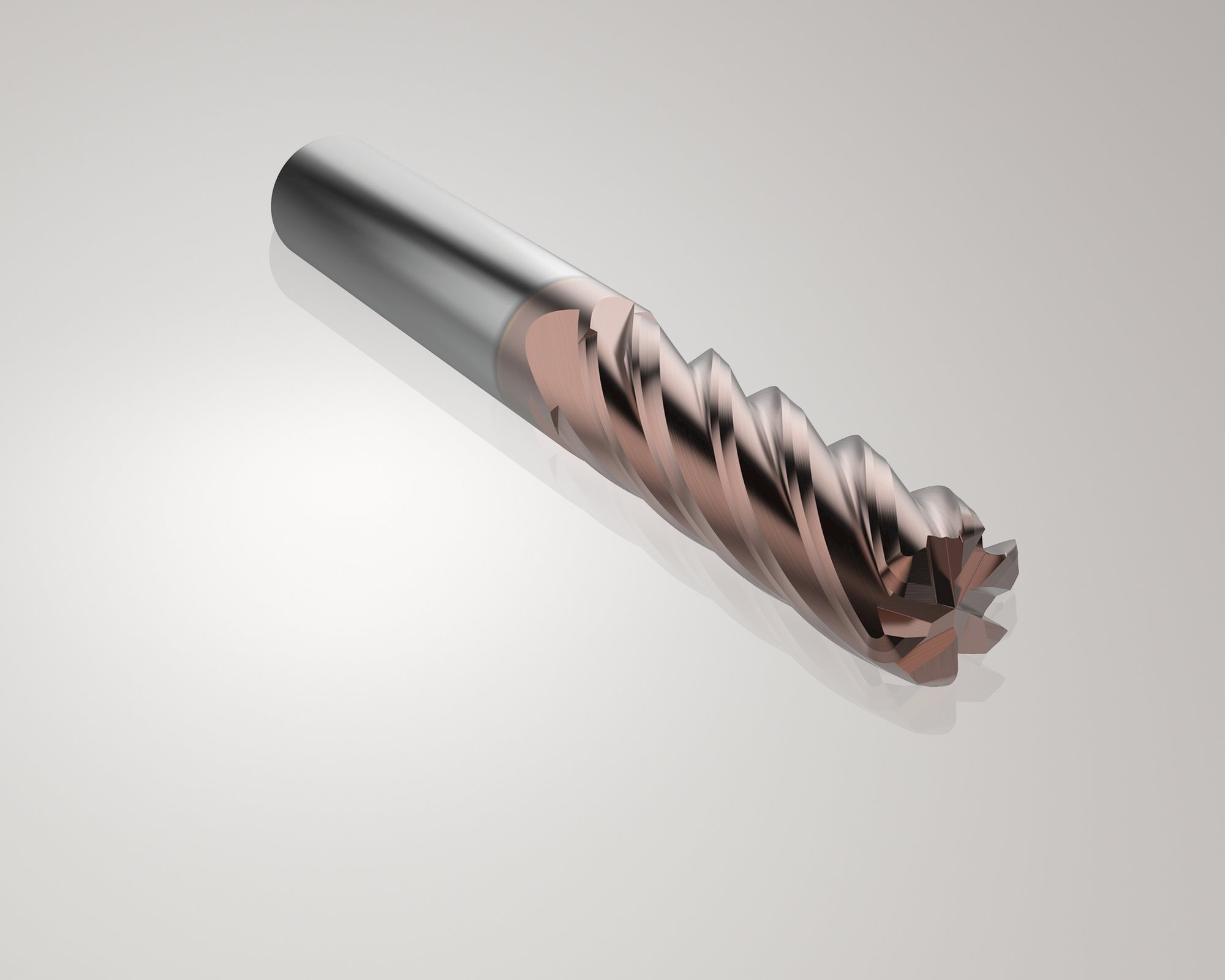

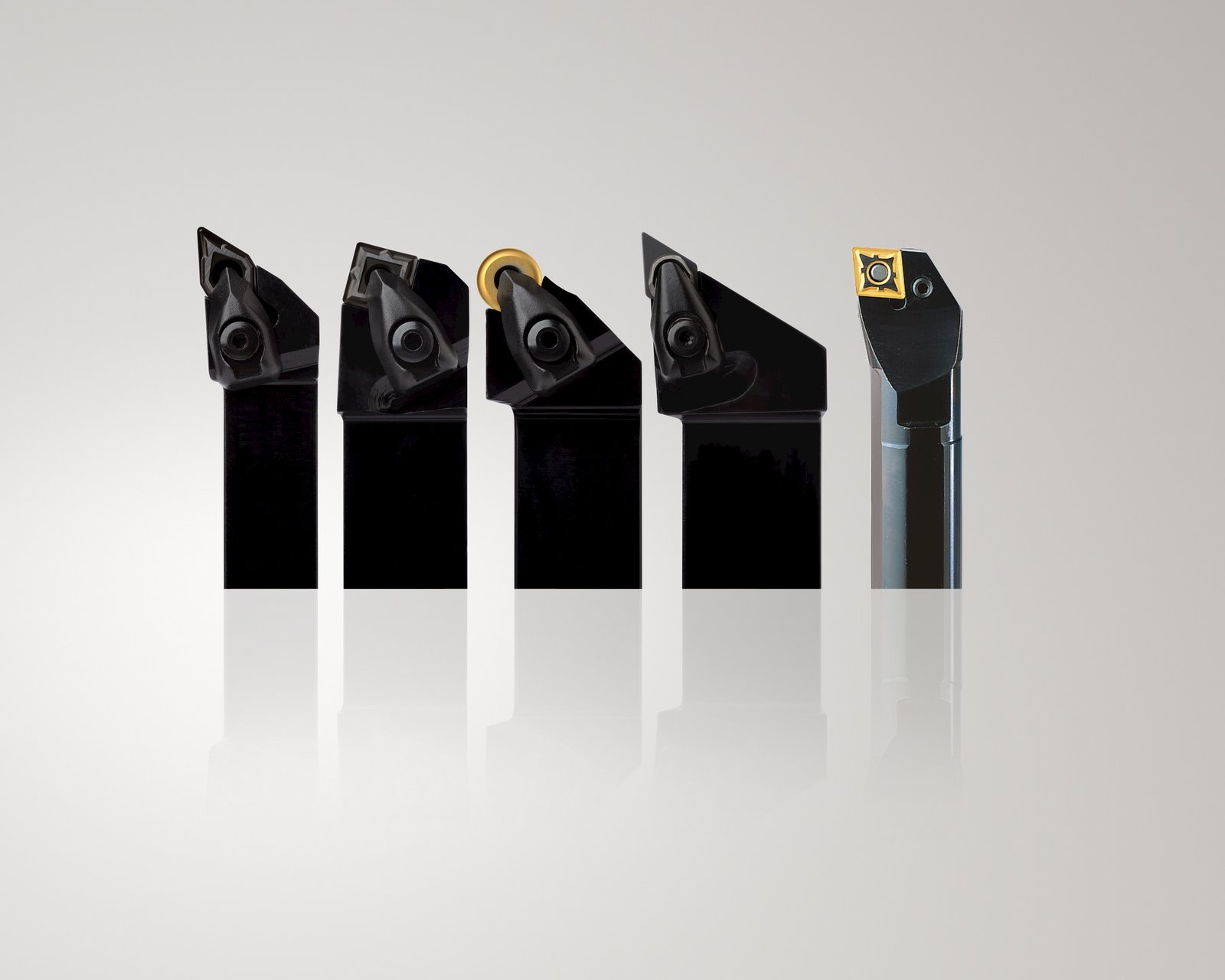

Dental product manufacturing machines everything from implants and crowns to bridges and partials. As a result, dental labs need a wide range of solid carbide end mill sizes and geometries to support unattended plug-and-play machining of dental components from a wide range of materials, including cobalt chrome, titanium, cubic zirconia, PMMA and wax. To support customers in the competitive world of dental product manufacturing, Seco provides a comprehensive portfolio of tooling specially designed to meet the needs of mid-sized to large lab facilities. Customers can order these tools with optional retainer rings.

Your challenge:

Support unattended machining of dental components for enhanced competitiveness.

The Seco solution:

Streamline production with a full range of sizes and geometries of metric high-feed, mini ballnose and torical end mills specifically designed for reliable, efficient, sustainable production of dental components.

Your challenge:

Implement plug-and-play tooling solutions for reliable pre-programmed machining in dental labs.

The Seco solution:

Order tooling specifically designed for dental machining with optional retainer rings preinstalled as a semi-standard solution.

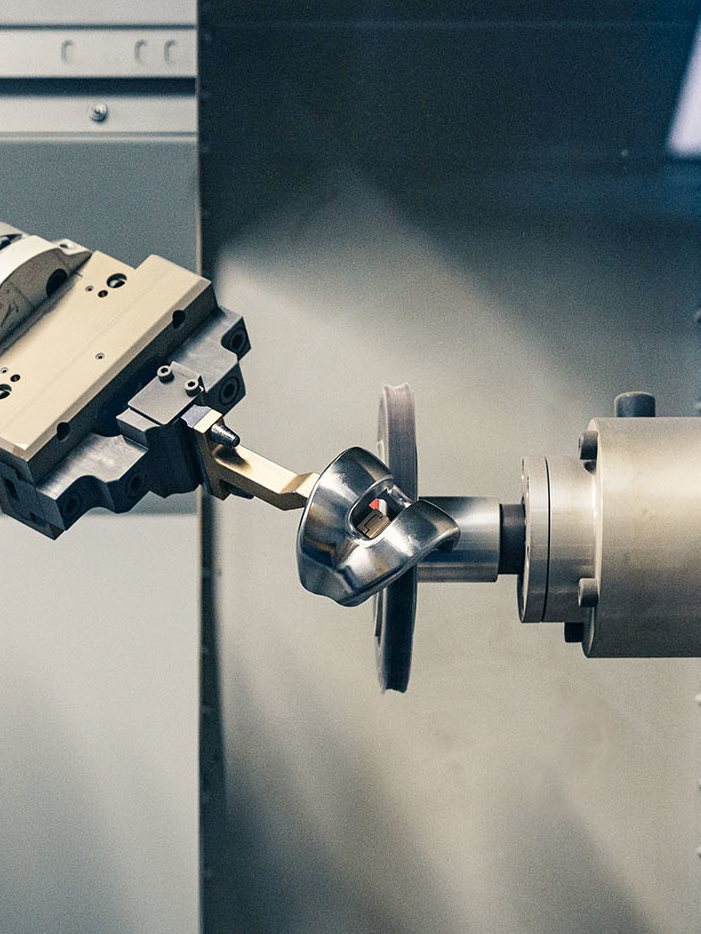

Dental manufacturing challenges labs to produce high quality precision components on various materials from milling titanium implants and bridge bars, to crowns and bridges made from chrome cobalt and the abrasive cubic zirconia, to the softer PMMA and wax dentures. The irregular contours of these components complicate the task of stable machining – and risk shortening tool life. To minimize cutting-edge breakage, tool wear and component chipping, specialized Seco solid carbide tools can help optimize your production for longer tool life and improve results in a highly competitive industry.

Your challenge:

Increase tool life on small, irregularly shaped parts in unstable machining conditions.

The Seco solution:

Reduce component chipping and tool breakage.

Your challenge:

Enhance the stability of the machining process on specialized dental components.

The Seco solution:

Use specialized tooling with optimized designs and geometries to lengthen tool life and enhance part quality with challenging materials.

Dental products manufacturers need to maximize their production efficiency to thrive despite intense competitive pressures. As a guaranteed supplier of solid carbide tools specifically designed for plug-and-play dental lab equipment, Seco helps these customers not only optimize their processes but expand the value of their products with greater knowledge of how best to produce critical parts from demanding materials. On a global scale, Seco offers all the insights and benefits of its deep industry expertise, serving as a partner to help customers succeed.

Your challenge:

Address all aspects of production reliability and efficiency for greater competitiveness.

The Seco solution:

Depend on highly trained salespeople who know the dental industry.

Your challenge:

Improve production consistency and process reliability.

The Seco solution:

Rely on a guaranteed source of supply for tooling in sizes and geometries specifically designed for dental production.

Dental manufacturing needs a continuous supply of solid carbide end mills in various sizes and geometries to produce crowns, bridges, implants and dentures from a long list of materials. With a single source of supply for a comprehensive portfolio of specialized tools, dental labs can avoid the need to maintain overly large tool inventories to offset long lead times on orders. Whether labs need their tools with retaining rings or longer neck lengths, Seco offers all the tooling options that the dental market requires, directly from standard stock and as semi-standard solutions.

Your challenge:

Source a comprehensive range of tooling sizes and geometries for complex dental machining.

The Seco solution:

One supplier offers all the tooling that dental labs need.

Your challenge:

Shorten the wait for tooling orders and limit tool overstocking.

The Seco solution:

Obtain a comprehensive dental portfolio with in-stock and semi-standard tools from a single supplier.

Discover the product range

Contact Us

Are you interested in Medical solutions?

Discover all our solutions and content around it

Related content

Dental Implant Components

Medical

Bridge and Bar

Crown

Abutment

Factsheet - Medical Dental Highfeed, Mini, Ballnose and Torical End Mills

PRESENTATION - DENTAL PODUCTS

Seco JH724-JH726 Medical barrel Solid End Mills

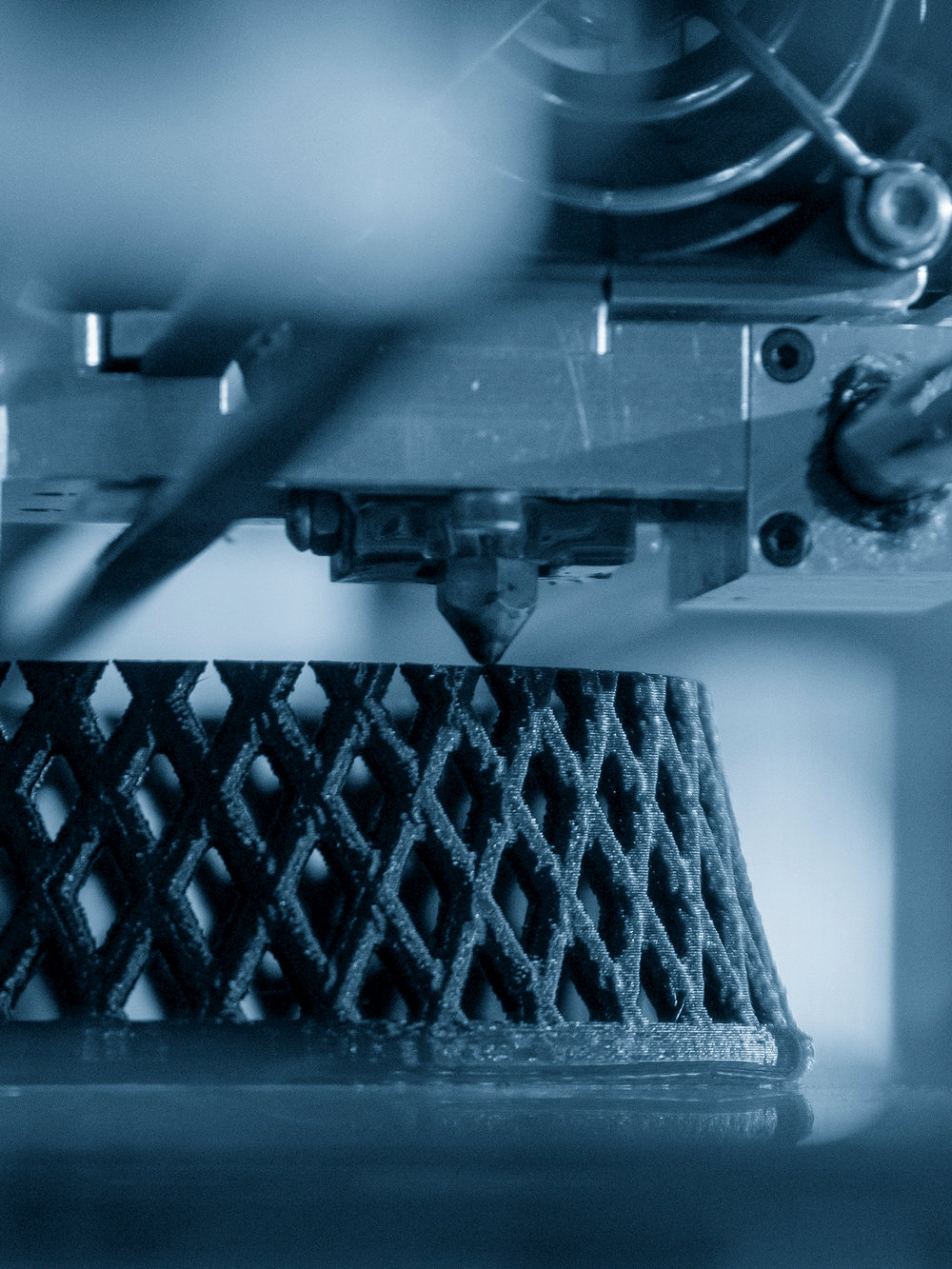

Challenges and benefits of Additive Manufacturing in the medical segment

ActOn’s ‘secret weapon’ is transforming medical implants

5 Additive Manufacturing Trends Enhancing Production and Tooling

8 tips to machine titanium alloys

Knee Replacement Components

Learn more about Seco Medical Solutions

Is this the future of orthopaedics?

Lingering effects from the Covid-19 pandemic in the knee implant surgeries market

PRODUCT PRESENTATION - JH724 JH726 MEDICAL BARREL

Inspiration Through Innovation 2024 Aerospace and Medical

Industry-specific solutions and strategies for machining ISO-S materials

Why a Strategic Partnership is the Perfect Medicine for Permedica

Medical Brochure

Meet the Mini Mills

New Seco Solid-carbide cutting tools boost knee implant machining speeds

Seco Taps T32 - T33 - T34

Inspiration Through Innovation

What does it take to engineer for tomorrow?

How 3D Printing is Making its Mark in Medical

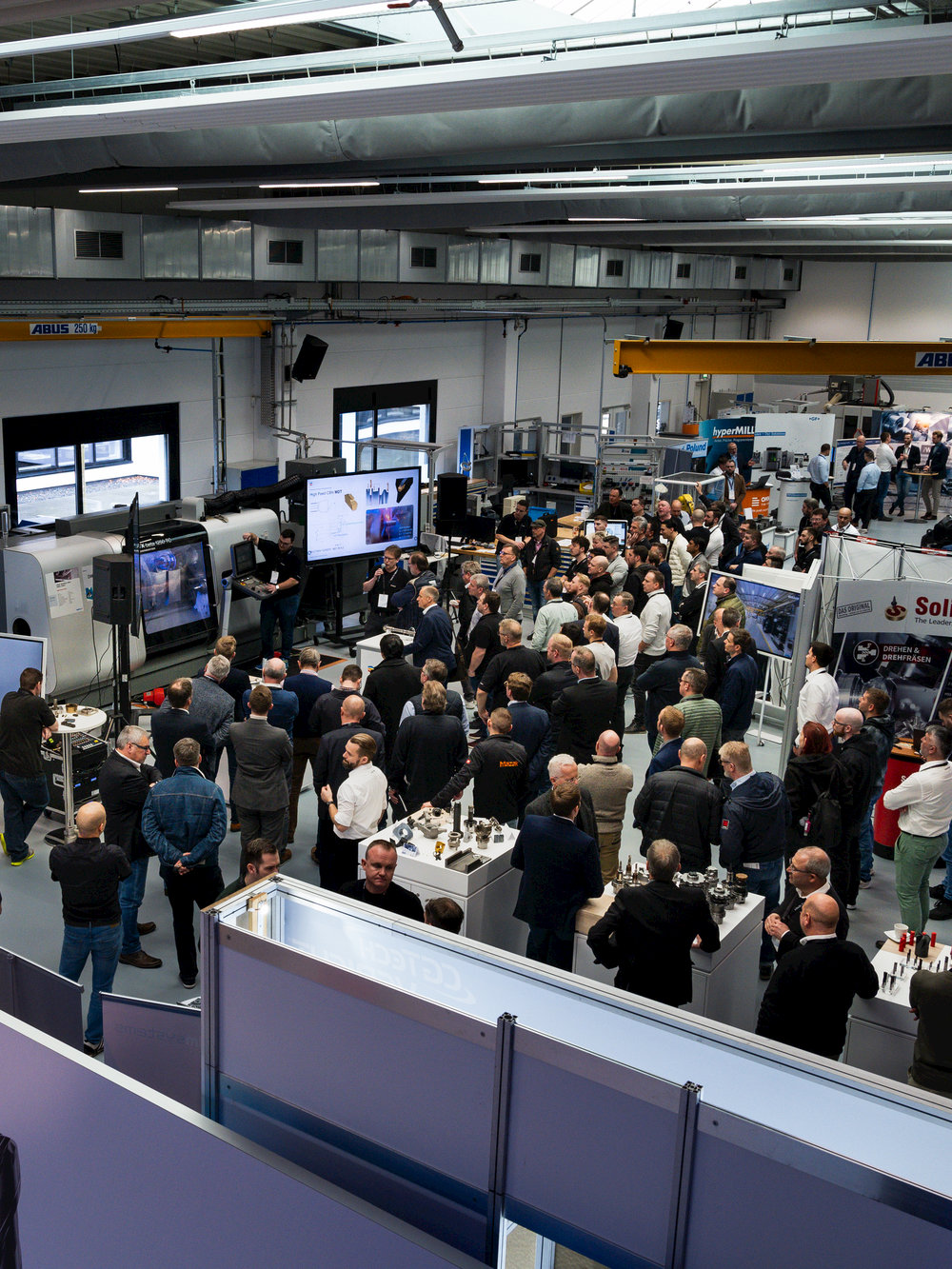

Inspiration Through Innovation 2024: Championing collaboration in the pursuit of manufacturing excellence

Seco Hydraulic Chucks

ITI 2024 | Medical Shoulder component machining demo

Fact Sheet JH724 JH726 Medical Barrel Solid End Mills

Hip Replacement Components

Seco Helical SN8-13

Factsheet - JH730 Solid End Mills addition

JCO710 - High Performance - Square - Titanium - 4-6 flutes

Spinal and Trauma Components

Seco High Feed SP

High Performance HSS-Co End Mills

Titanium: Mastering Today’s Challenges, Shaping Tomorrow’s Trends

Contact our medical experts

JH730 Solid End Mills addition

Seco News Summary 2022.2

Finish Stock Allowance with Solid End Mills

Good news from Cobalt study

HSS-Co End Mills

Femoral Knee Implants – a new manufacturing paradigm

Seco JS754 Stub Series End Mills

Brochure - Product Highlights

Seco collaborates with GF on machining specific medical components | Seco Tools

Shank Toolholders and Boring bars

JETSTREAM TOOLING® SECO CAPTO™ GENERAL ISO TURNING

Medical ITI - A Precision medical manufacturing event | Seco Tools

Seco supports Medical innovation with virtual event and exclusive content

Industries

Seco JM500 delivers visible improvements for micromachining

New strategies for orthopedic machining

Intelligent future

Front-Runners

Milling tooling developments increase quality and productivity in the machining of orthopedic replacement components