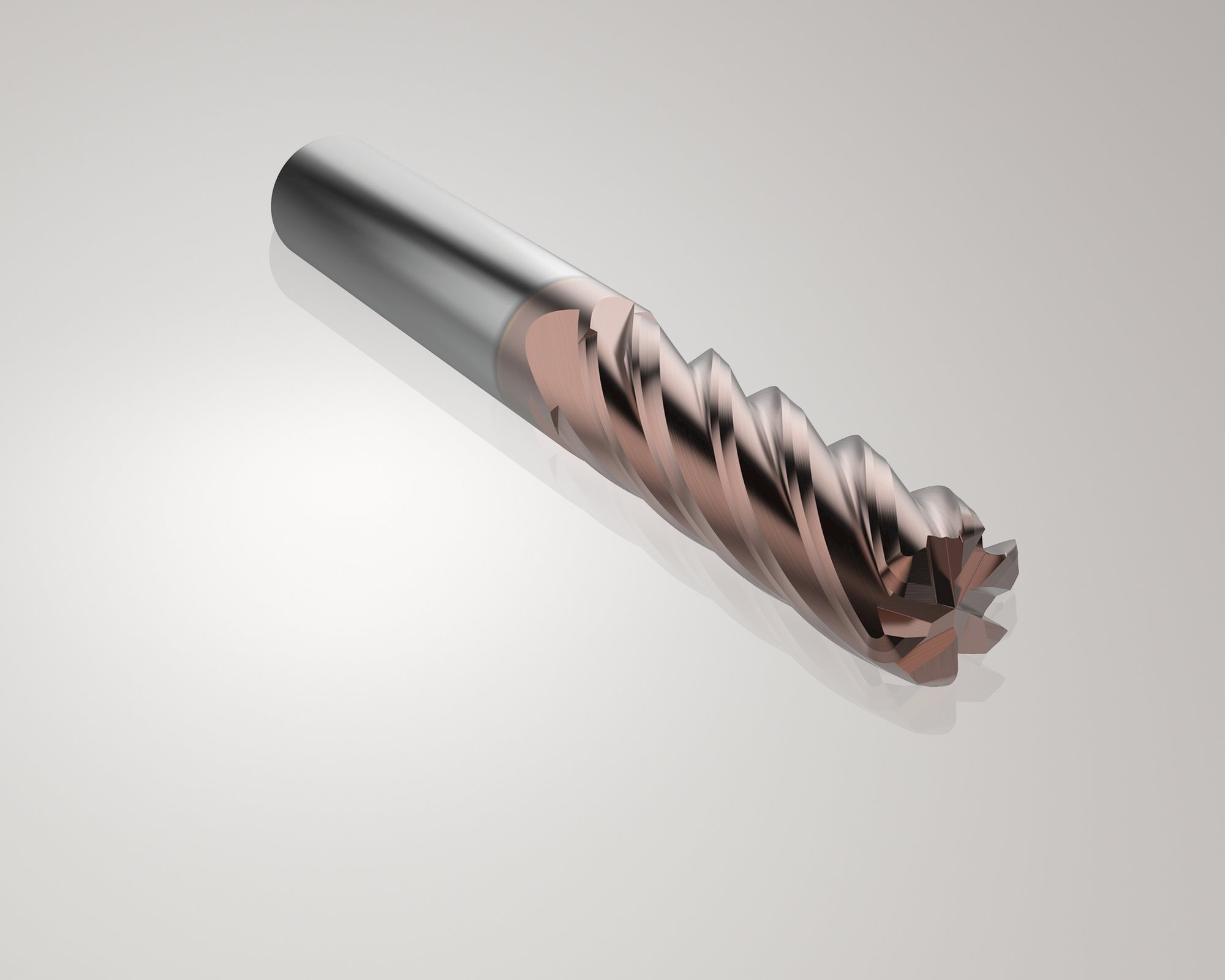

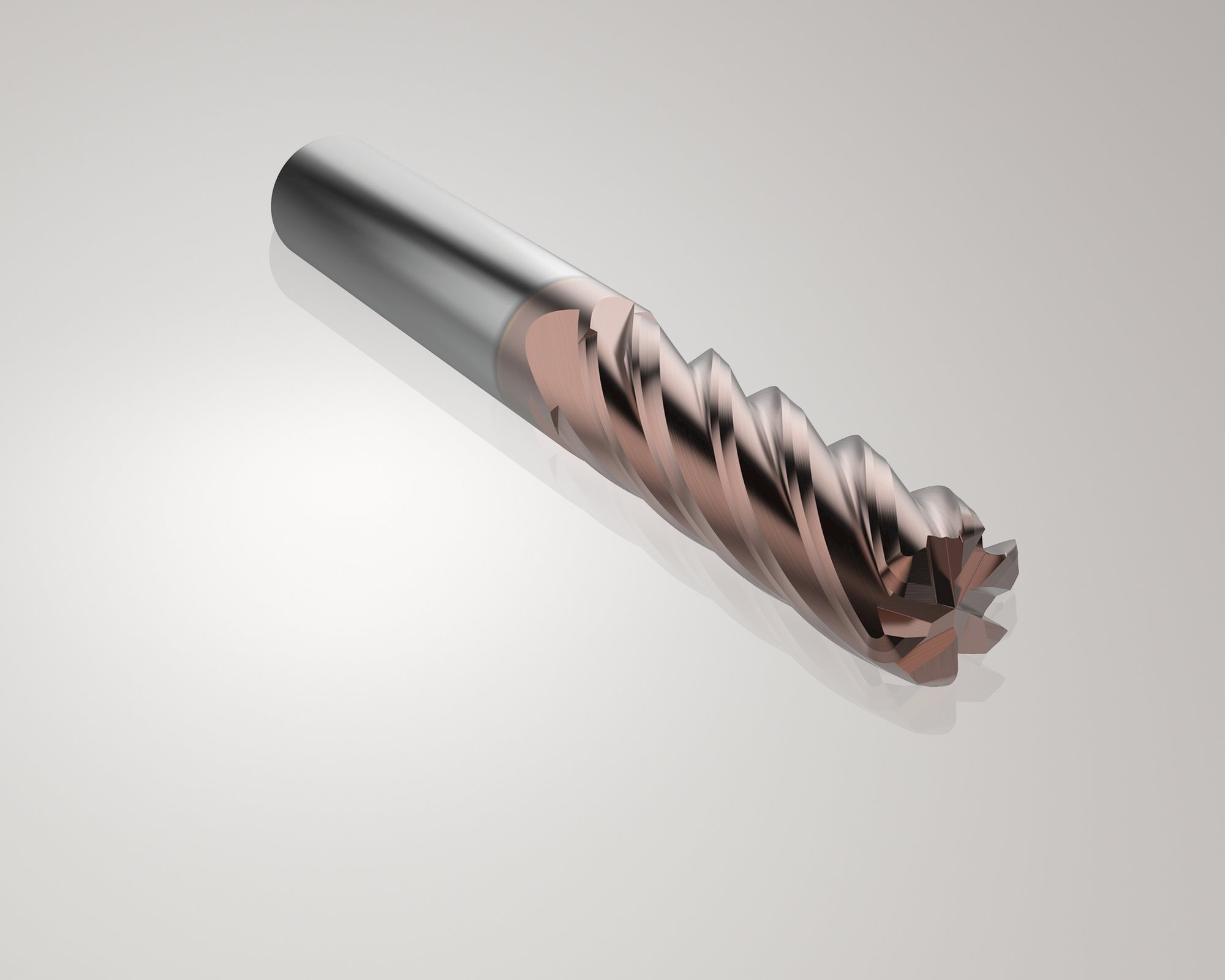

JH730 Solid End Mills addition

Lower your costs per part while increasing precision orthopedic productivityDiscover the product range

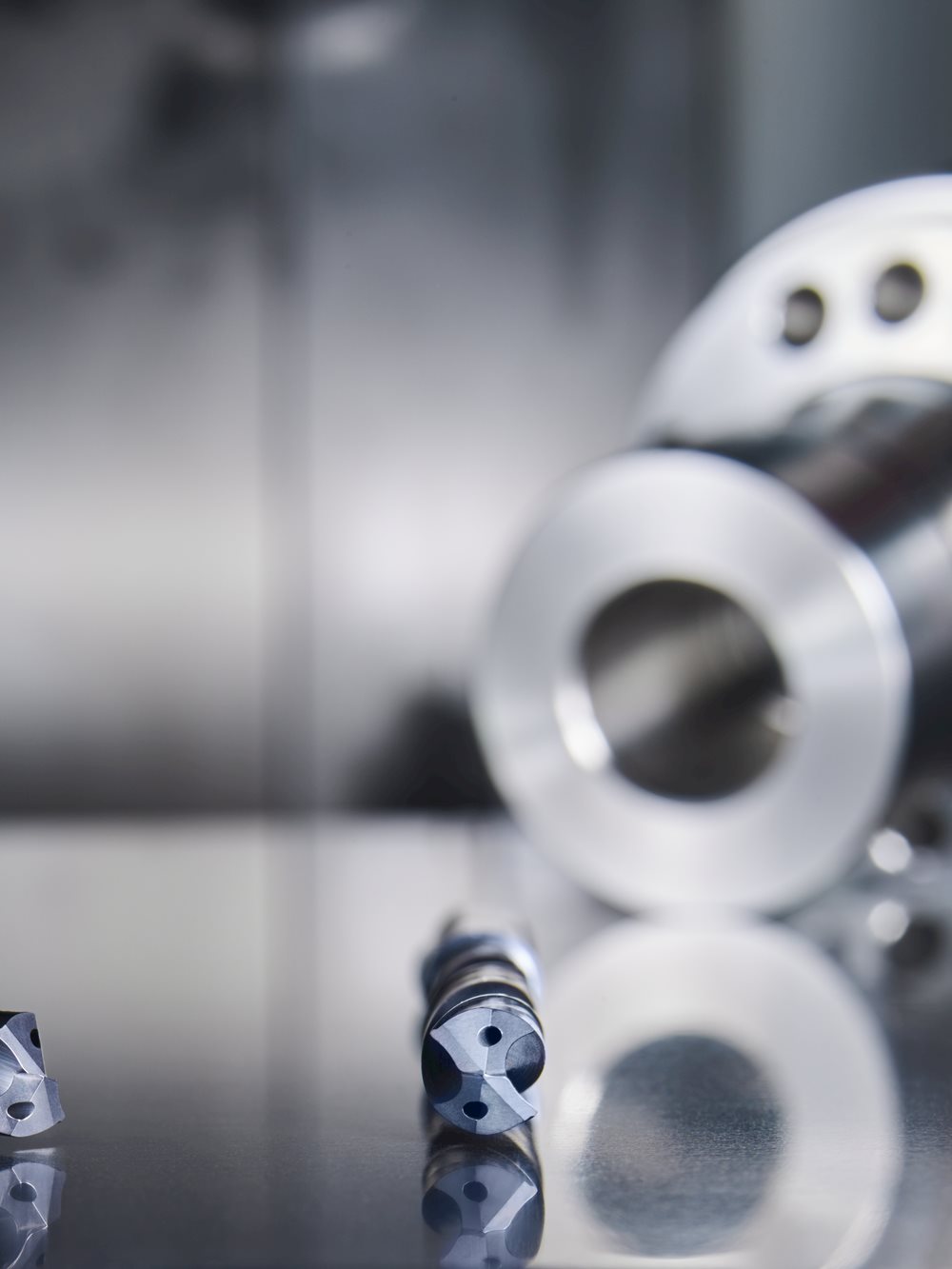

As the global population ages, the precision medical manufacturing sector has seen significant growth. Maintain your lead in this competitive market with a fully optimized and complete set of solid end mills for orthopedic part production.

This standard ten-tool set was designed by medical industry experts to perform the full range of orthopedic implant milling applications with the efficiency you need for the lowest cost per part.

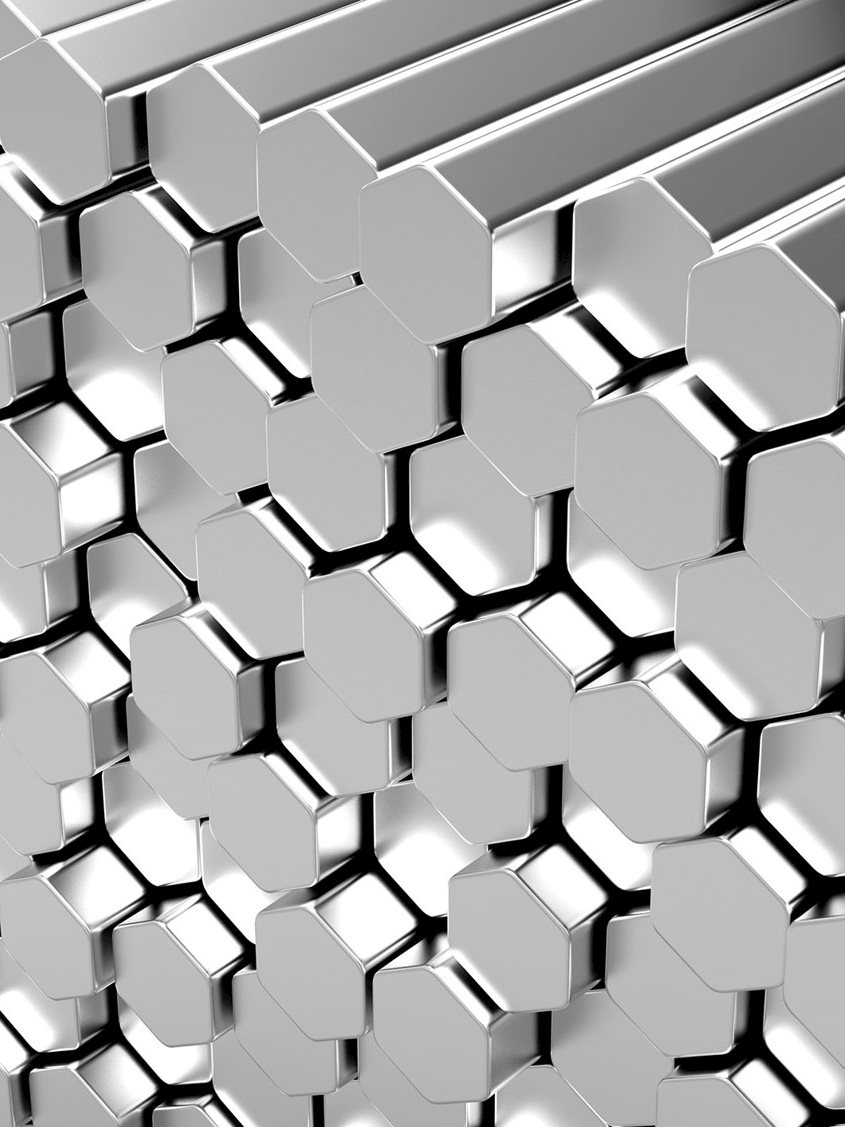

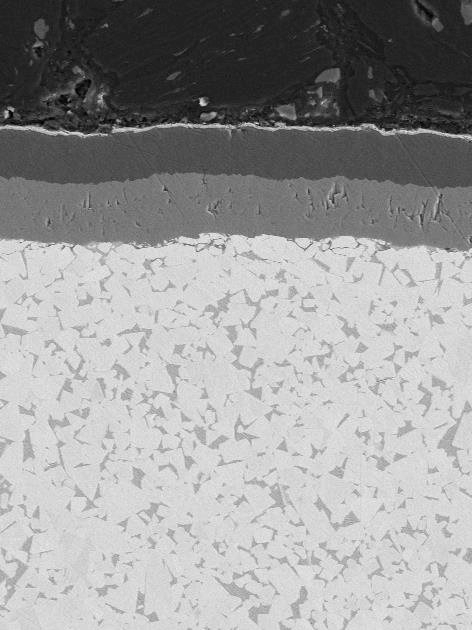

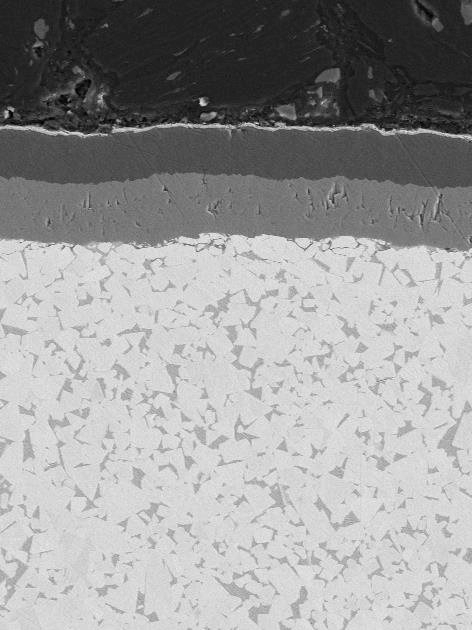

Each process-specific tool has an HXT coating optimized for performance and reliability in ISO-S and ISO-M materials, while short flute lengths provide additional stability, strength and cost-efficiency.

Your challenge:

The increased demand for orthopedic products has made the medical parts industry more challenging than ever.

Our solution:

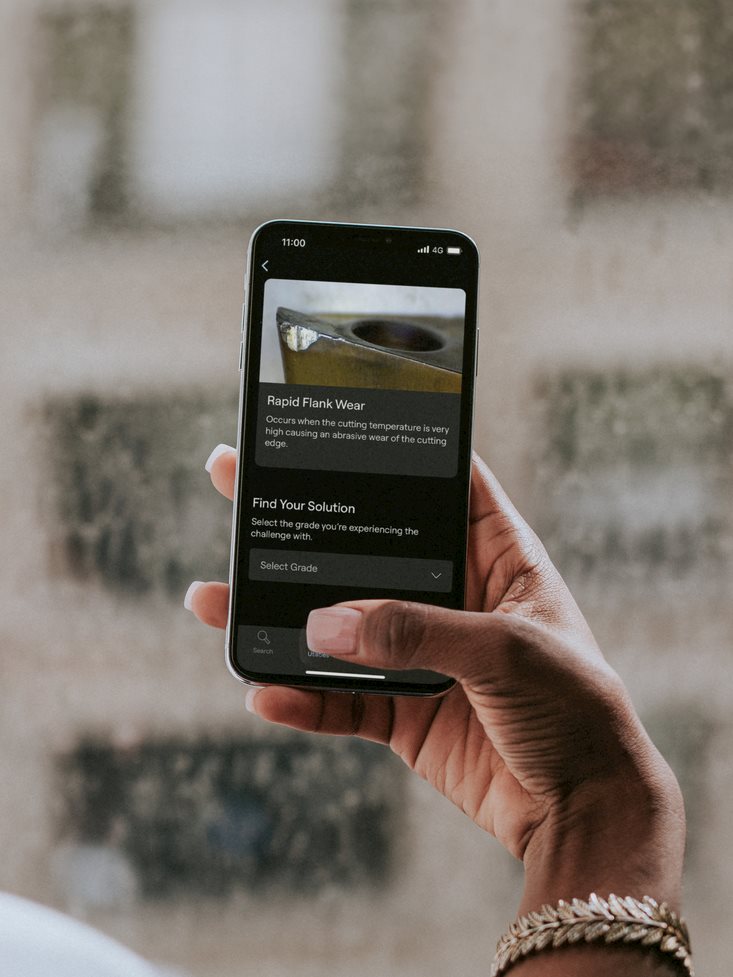

Increase output and improve lead times by streamlining your medical part production and creating optimal, sustainable processes with expert application support from Seco.

Your challenge:

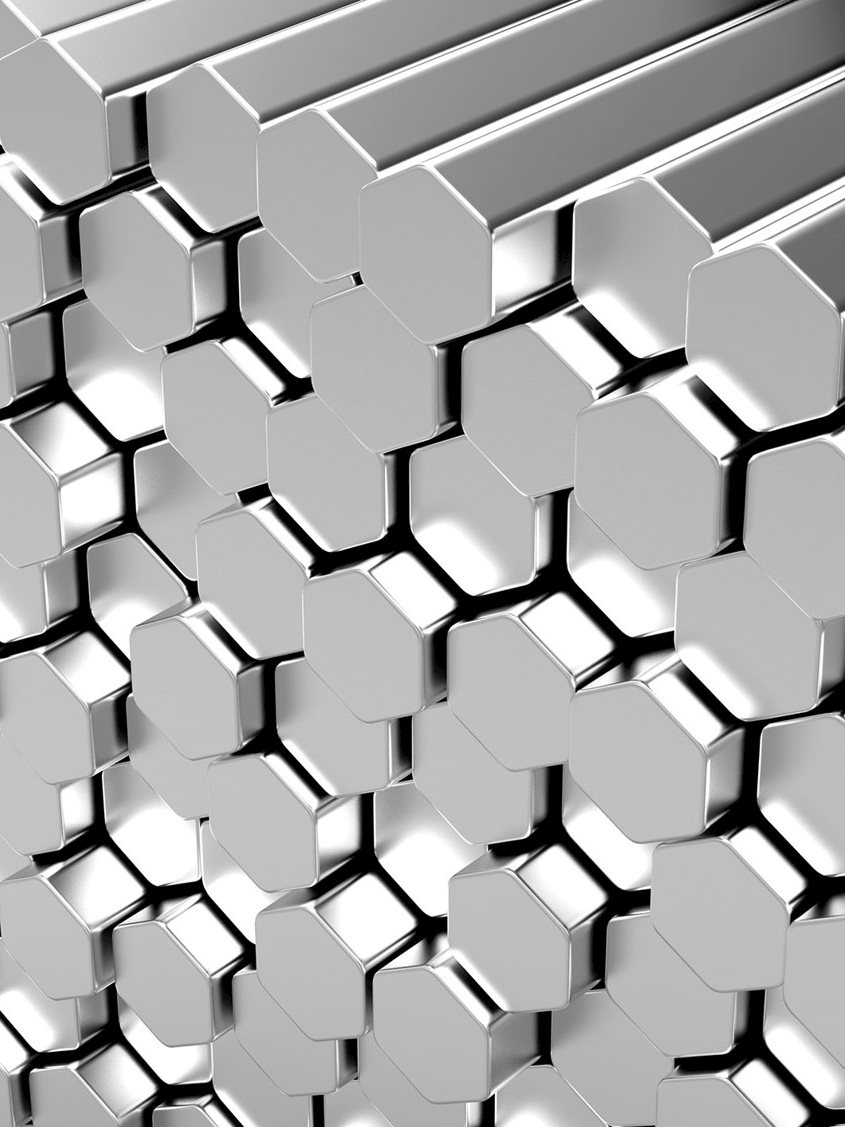

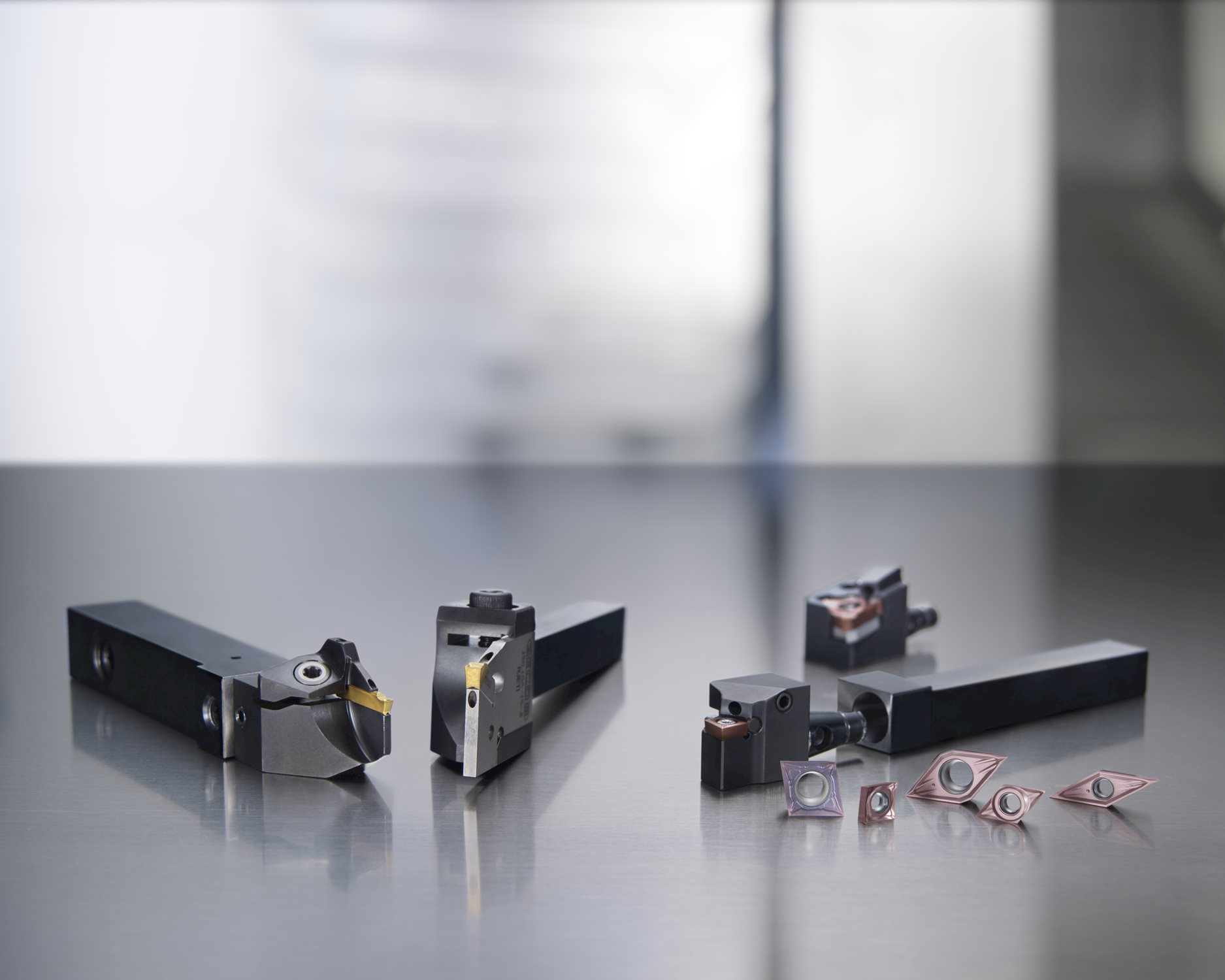

Difficult-to-machine titanium, cobalt chrome and stainless steel materials, common in medical industry applications.

Our solution:

Handle challenging ISO-S and ISO-M materials and achieve superior tool life with HXT-coated end mills, developed for effective thermal and wear resistance.

Your challenge:

Difficulty to machine small size box blends on a Femoral component.

Our solution:

New diameter dimensions added to the already existing JH730 series to offer more opportunities.

Discover the product range

Contact Us

Related content

Barrel Tooling - Online Course

JH730 High Speed - CoCr and Titanium - Square - 5-6-7 Flutes

Seco JH724-JH726 Medical barrel Solid End Mills

Factsheet - JH730 Solid End Mills addition

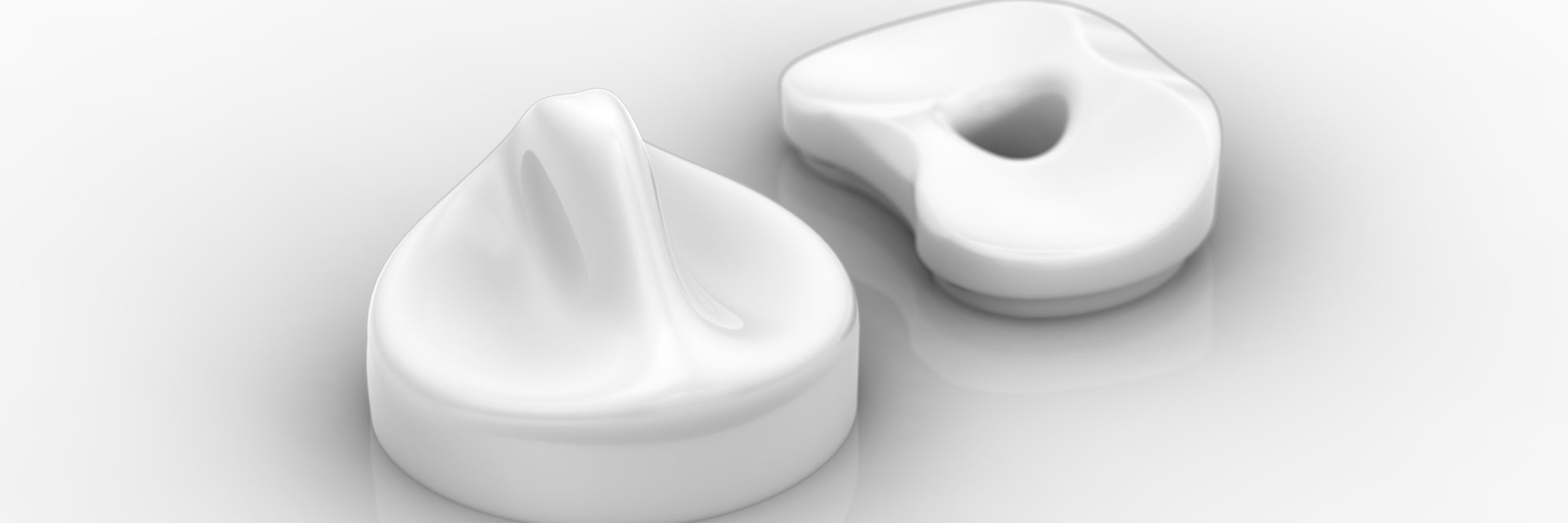

Knee Replacement Components

PRODUCT PRESENTATION - JH724 JH726 MEDICAL BARREL

JS720 Solid End Mills addition

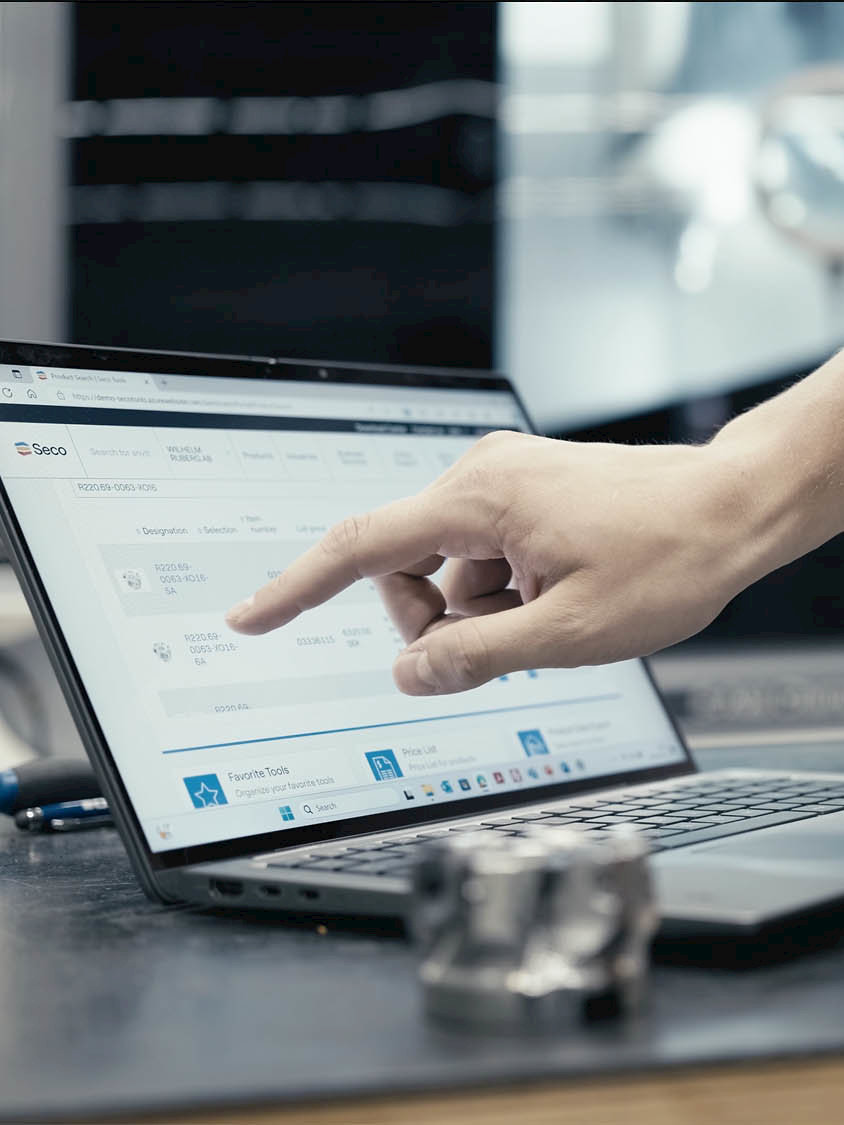

Seco Digital Tool Assembly: quick, accurate data

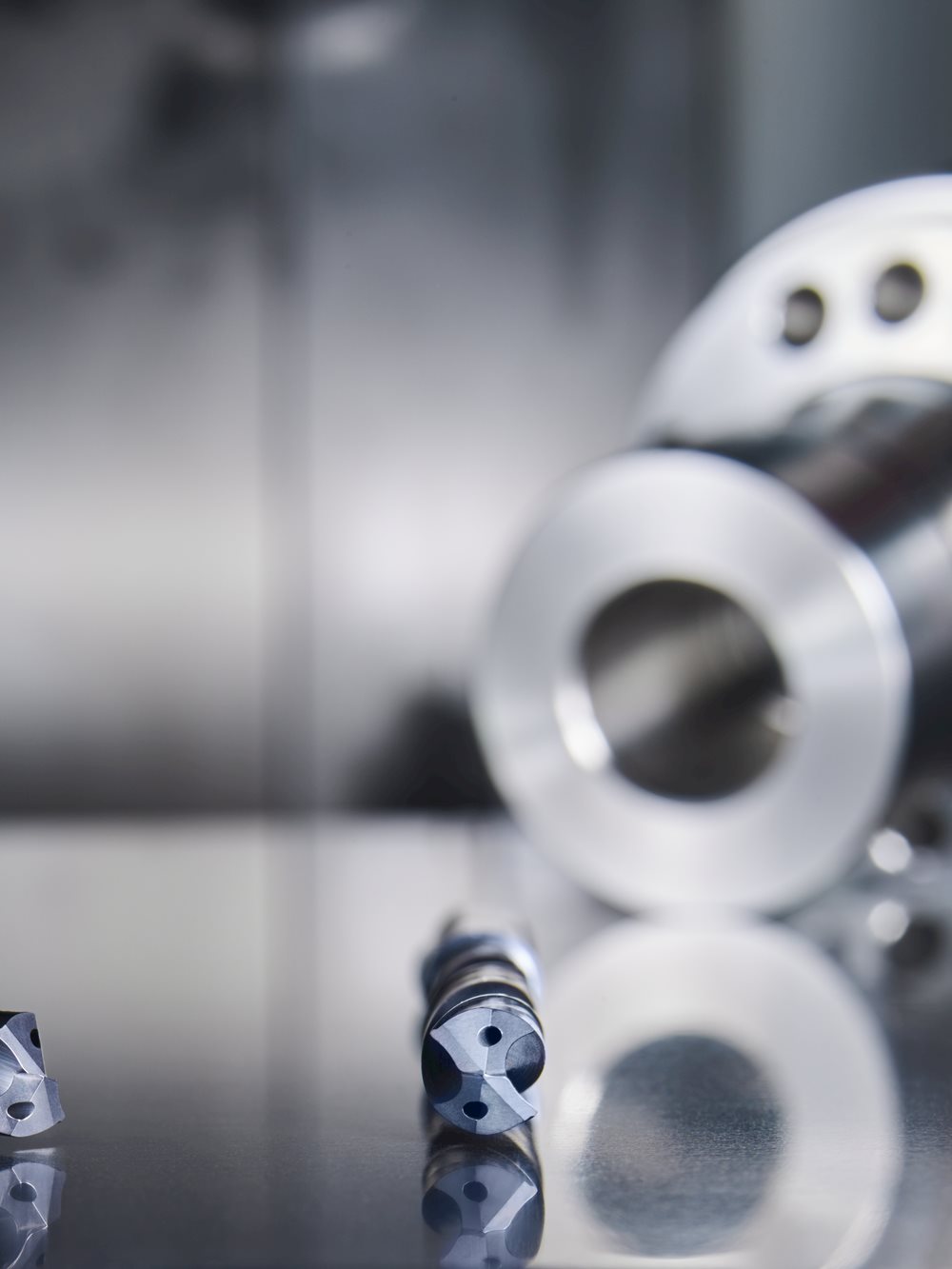

Seco Nanojet Reamers: reliable precision

Easy setup with Seco Digital Axial Boring Heads

JH724/JH726 - High Speed - Taper Shape Medical - CoCr/Titanium - 4-6 Flutes

Square T4-12 Upgrades

Challenges in stainless steel

Challenges in titanium

Fact Sheet JH724 JH726 Medical Barrel Solid End Mills

Medical

Optimize Multi-Task Machining Coolant And Results

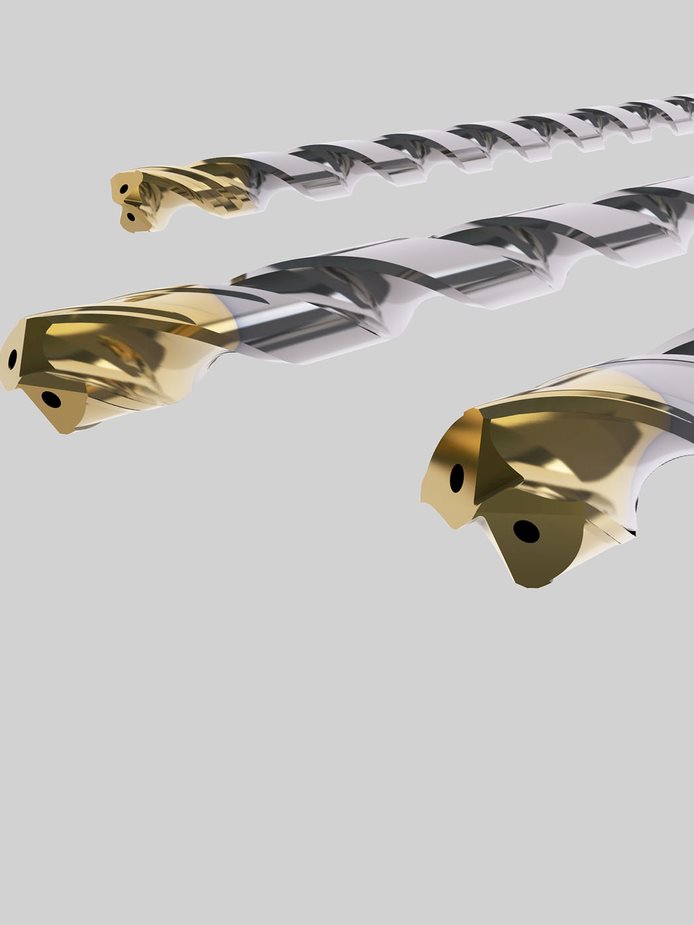

Seco X-Tra Long Solid Carbide Drills – 40xD-60xD

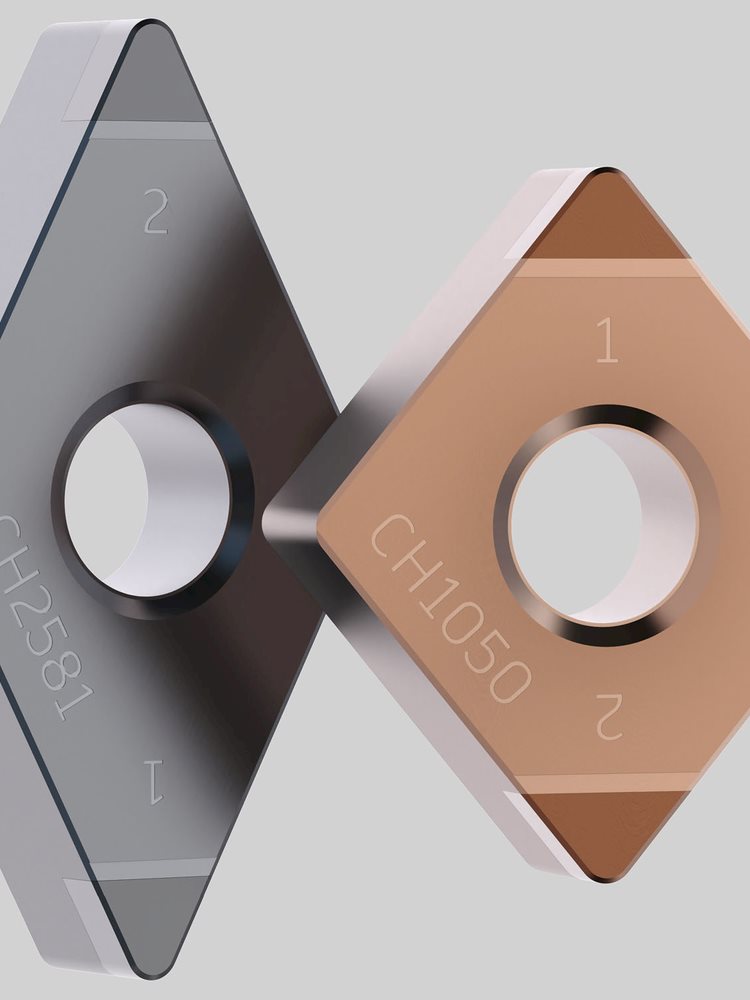

Seco CH1050/CH2581 PCBN Hard Part Turning Inserts

Learn more about Seco Medical Solutions

Universal Drills

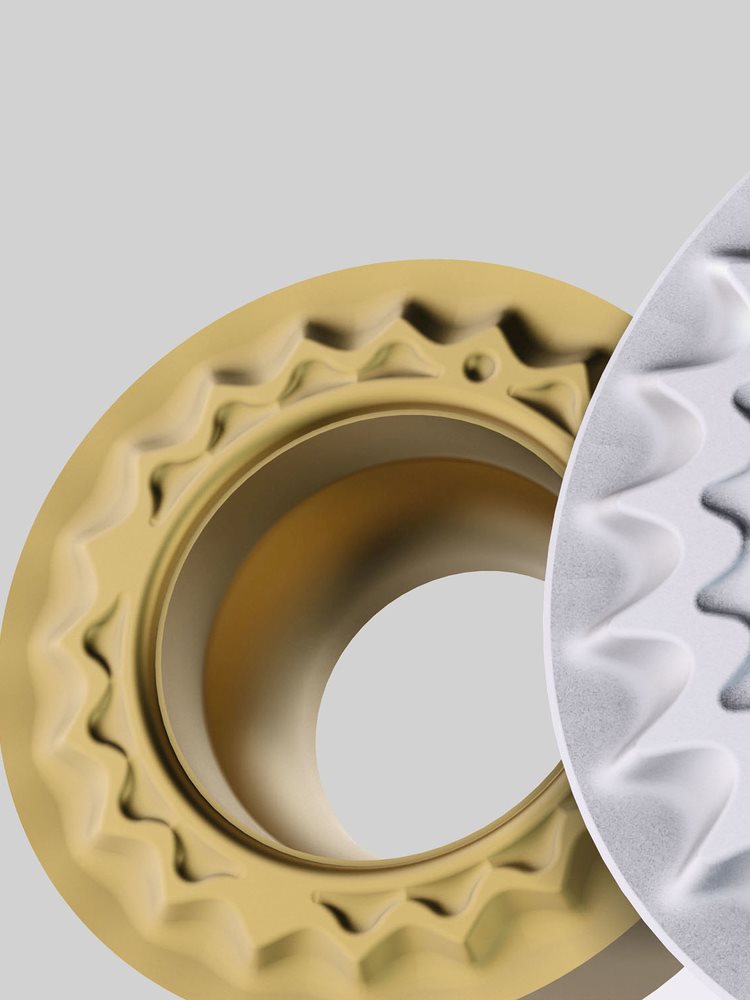

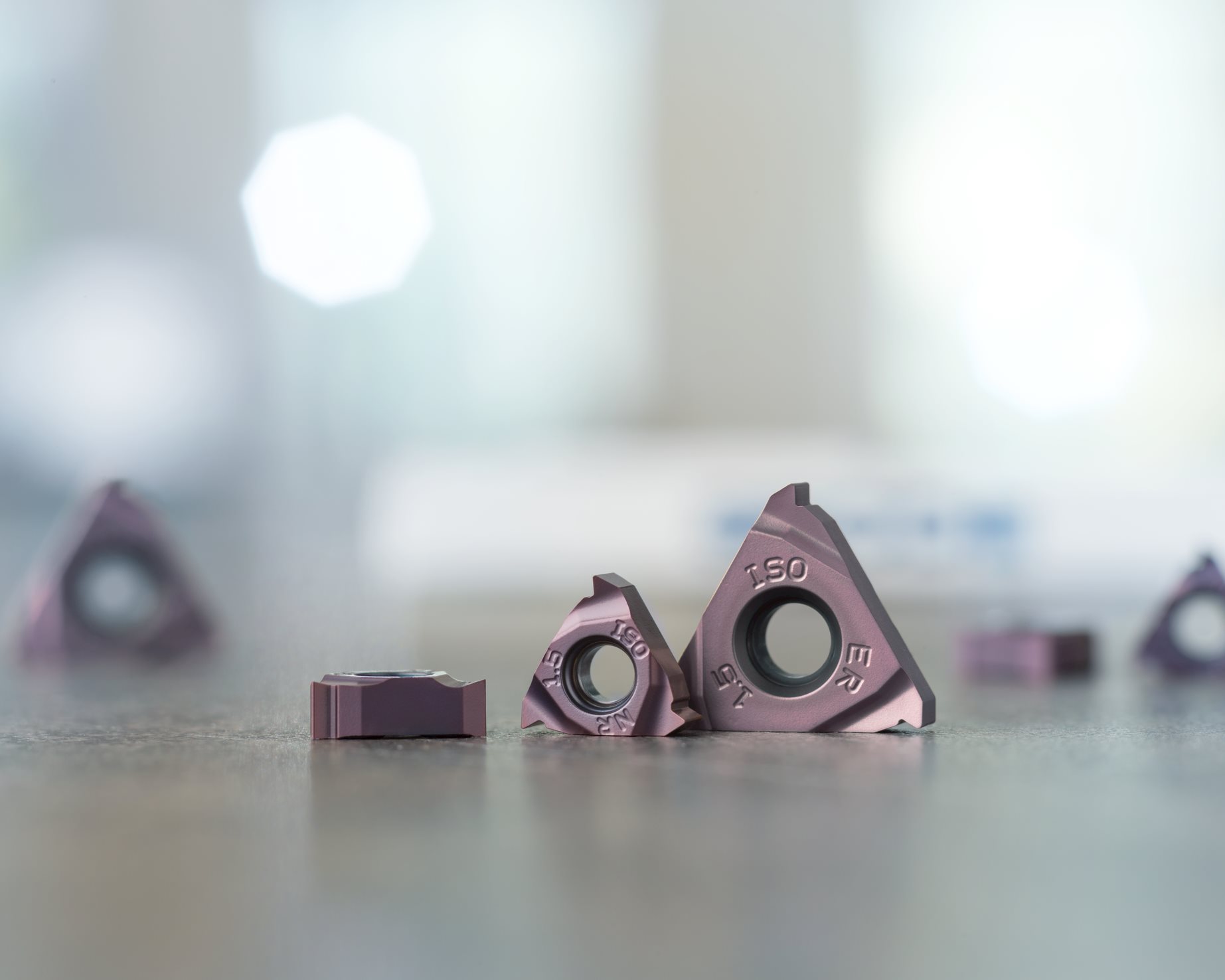

MF2 Chipbreaker on Round RCMT/RCGT Inserts

Is this the future of orthopaedics?

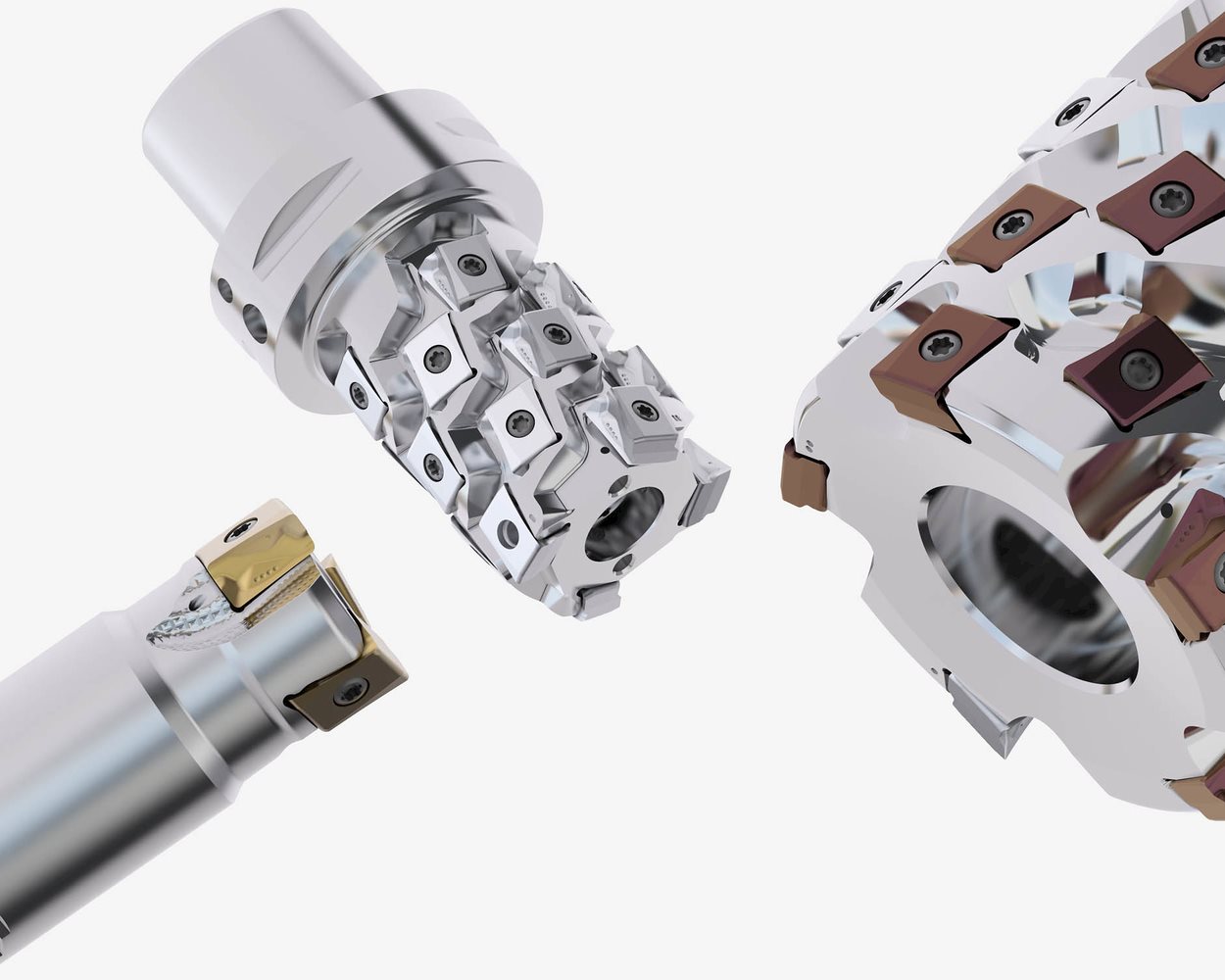

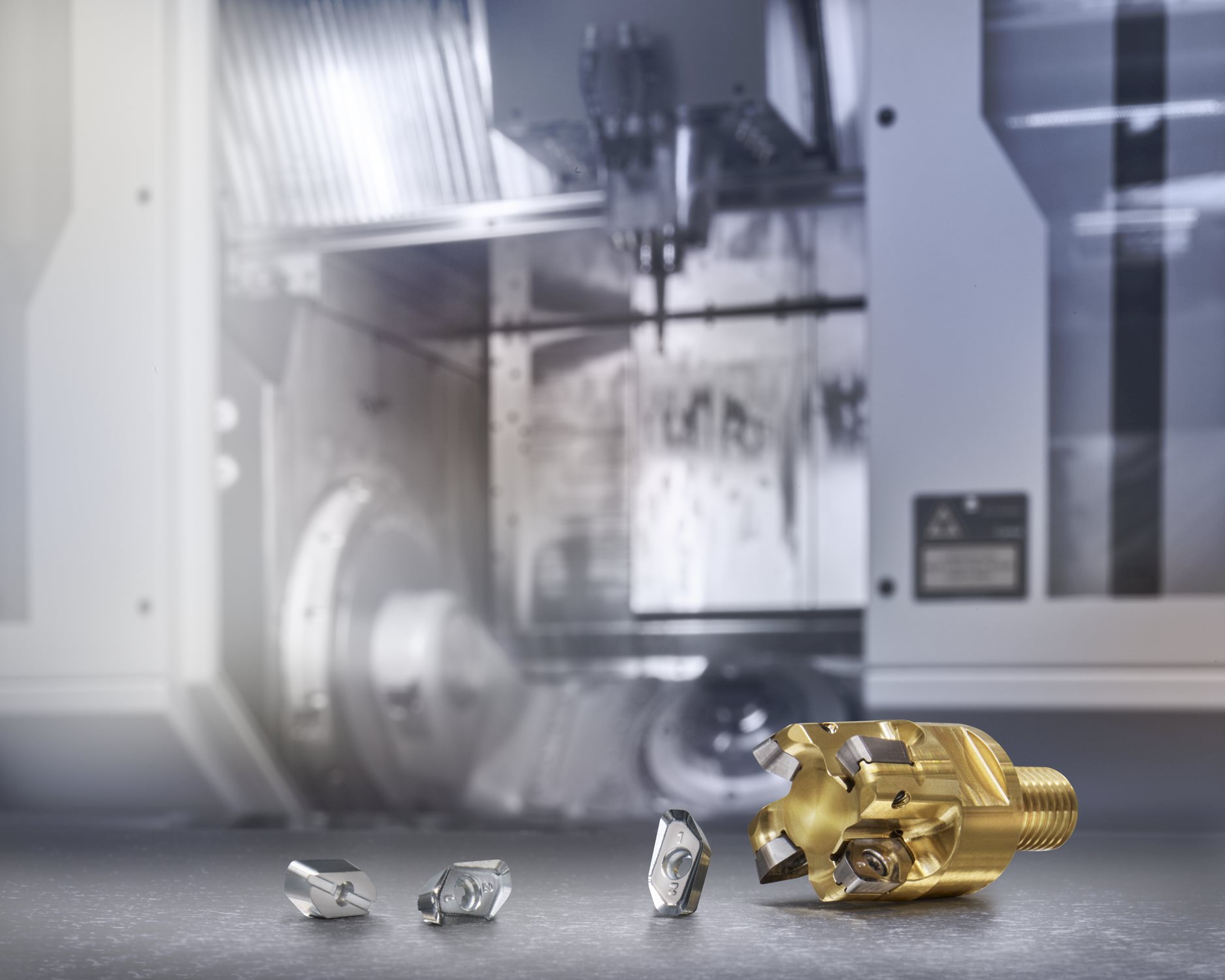

TURBO 16 SQUARE SHOULDER MILLING CUTTERS

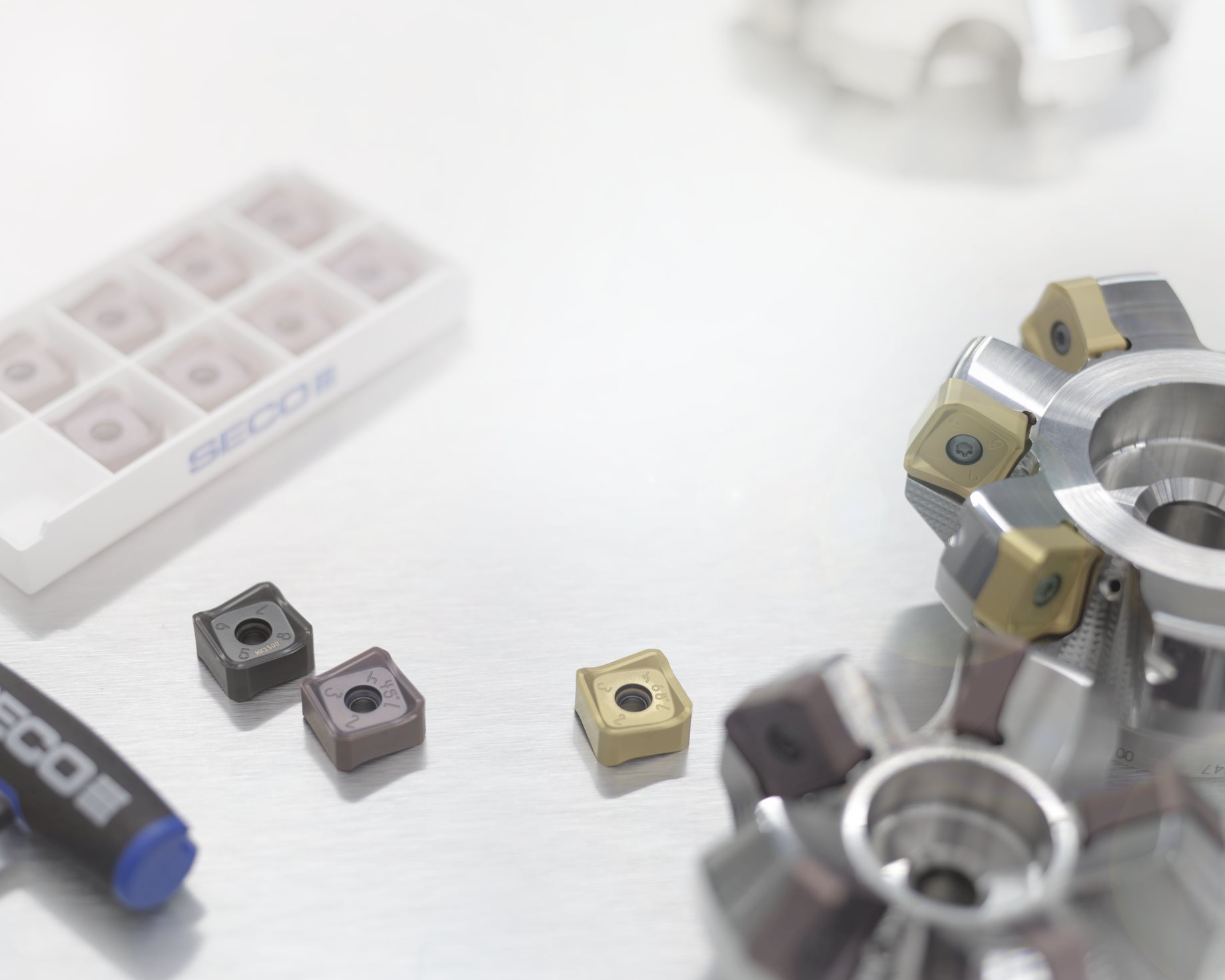

New MP Milling Grades

8 tips to machine titanium alloys

Femoral Insert

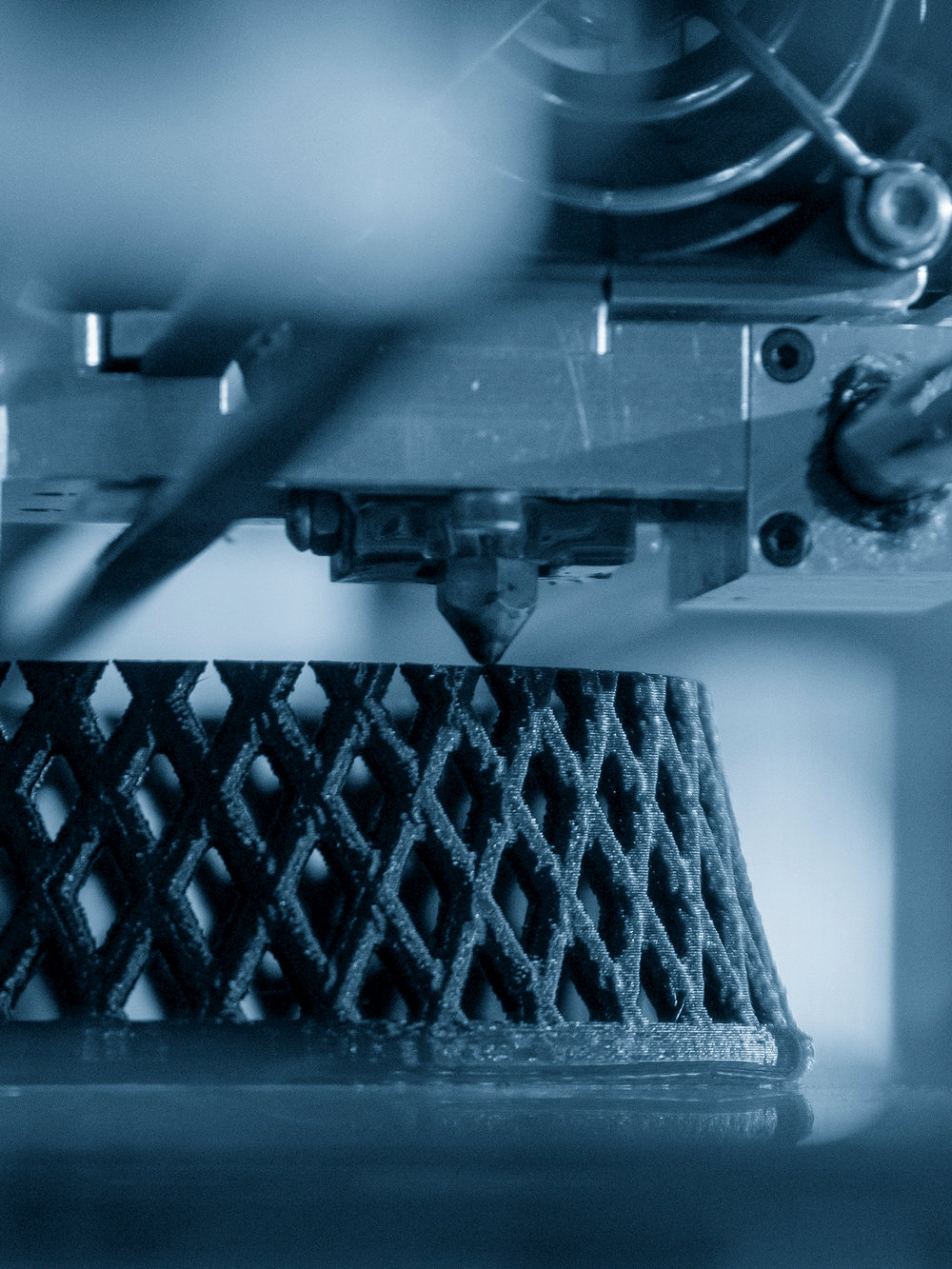

Challenges and benefits of Additive Manufacturing in the medical segment

ActOn’s ‘secret weapon’ is transforming medical implants

Lingering effects from the Covid-19 pandemic in the knee implant surgeries market

Finish Stock Allowance with Solid End Mills

Seco X-Head Exchangeable End Mill System

Industry-specific solutions and strategies for machining ISO-S materials

Seco Barrel Machining Tools - JH734/JH736 & JH744/JH746

FINISH 3D PARTS FASTER WITH NEW BARREL FINISHING TOOLS DEDICATED TO ISO M AND S MATERIALS

Advances in superalloy machinability

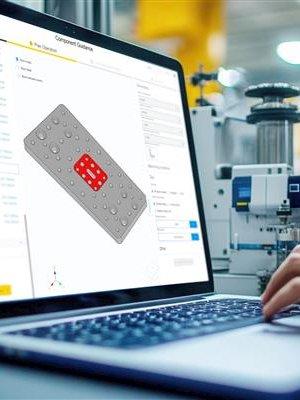

Seco Component Guidance

Versatile Round 20 Inserts Increase Tool Life

Seco Octomill™ 06: Flexible, Robust Tooling

Seco Stabilizer Series: Unmatched Metal Removal

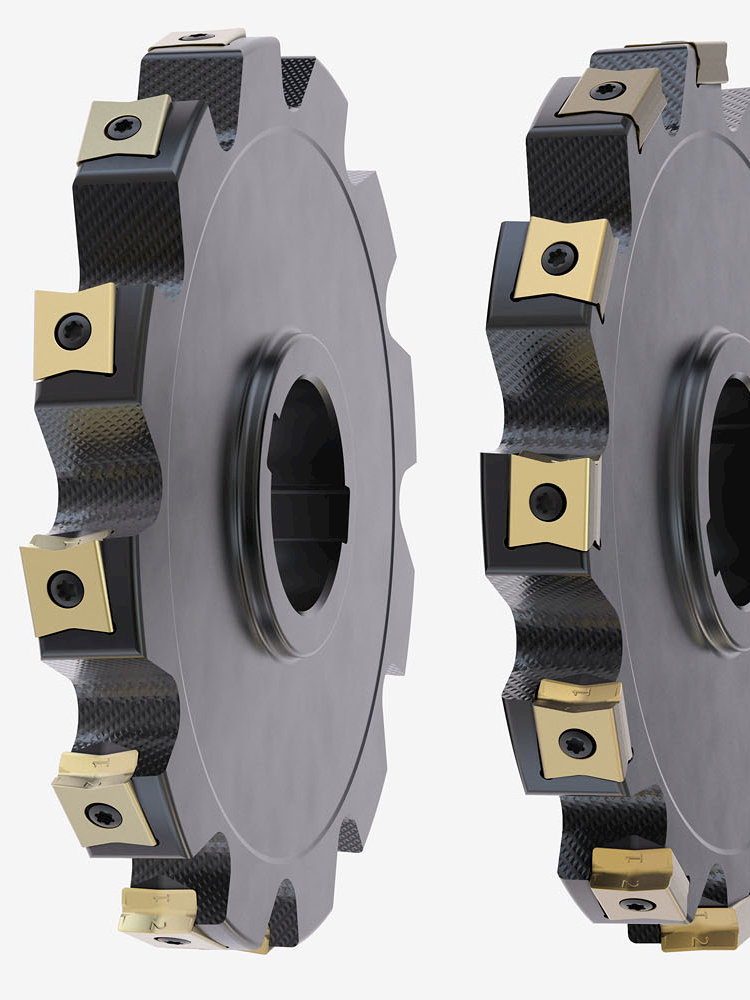

335.14 Disc Milling Cutter extension

Seco T30 Taps: a versatile universal geometry

Seco 335.98 Disc Milling Cutter system

Seco My Design: Design custom tools

Seco Machine Library

Seco T35 Taps: match Tooling to Materials

Seco Helical LN4-11 Milling Cutter

Guillaume Bourderon appointed Sales Unit Market Manager France

JETI CONVERSION GROOVING AND PARTING-OFF

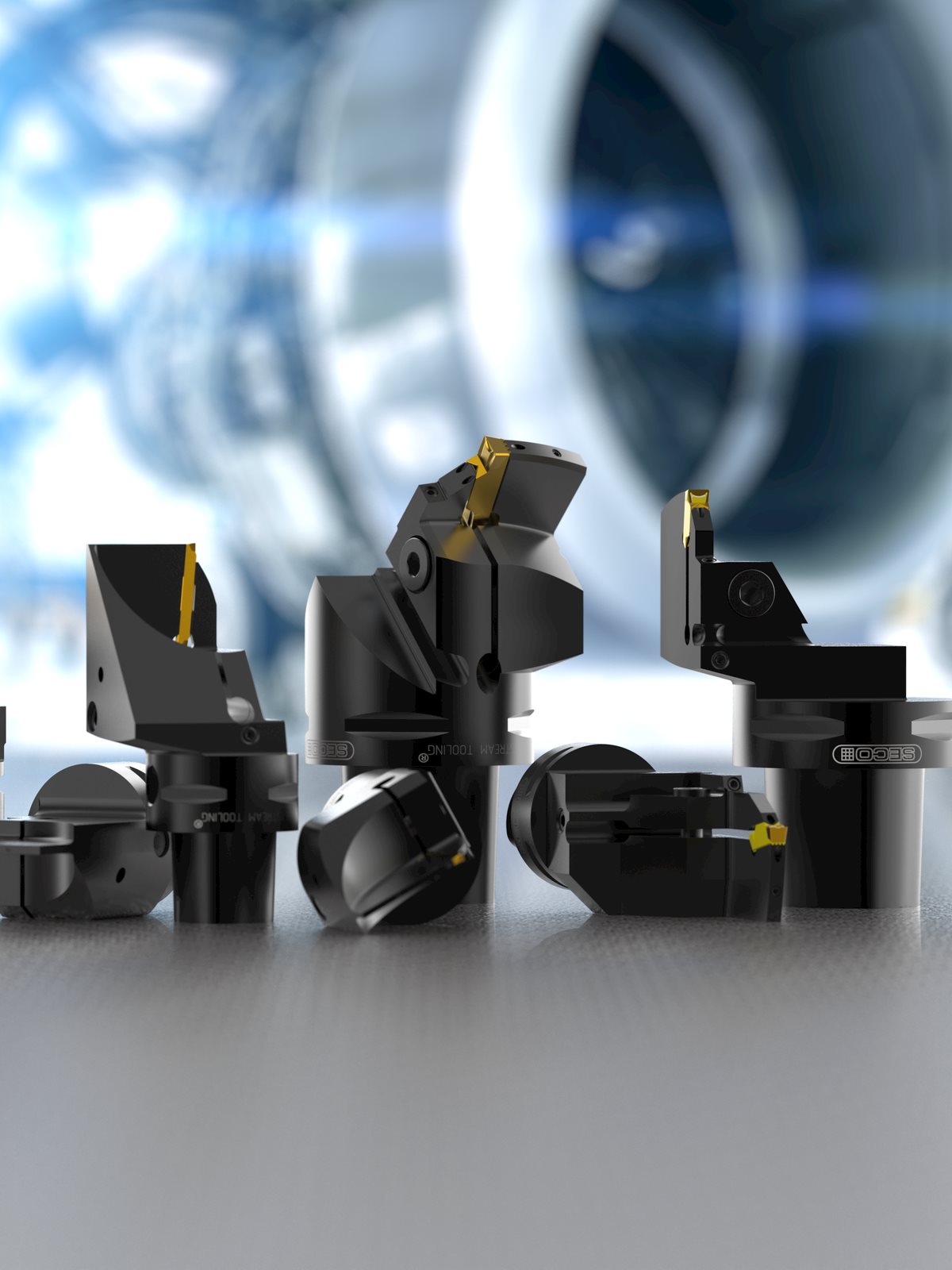

Seco X2 System for Small Part Machining

JETI Toolholder for RCMT/RCGT Turning Inserts

Seco S43/S45/S46 Solid End Mills for Aluminum

Turbo 12 & 18 Chip Splitter Inserts

Seco C-Series General Purpose End Mills

Steadyline® ø25mm (1”) series

Unleash your drilling potential

Medical Brochure

Femoral Knee Implants – a new manufacturing paradigm

JETI ISO Toolholder range extension

JETI conversion Grooving and Parting-off Capto

New strategies for orthopedic machining

JM100 MINI END MILLS

New Seco Solid-carbide cutting tools boost knee implant machining speeds

Modular QC (quick-change) toolholder for small part machining

SECO-CAPTO TOOLHOLDERS & CASSETTES FOR ADVANCED MATERIAL

XP08 ALUMINIUM ROUTER

RANGE EXTENSION OF SHELL MILL HOLDERS, SMALL FACE & SIDE LOCK HOLDERS IMPROVEMENTS

COMBIMASTER™ M20

EASYSHRINK EVO

UNIVERSAL DRILLS 8XD AND 12XD

SECO ROUND 10 AND 16 COPY MILLING INSERTS

DOUBLE TURBO 16

High Feed square cut size 14 insert

ISO K THREADING TAPS

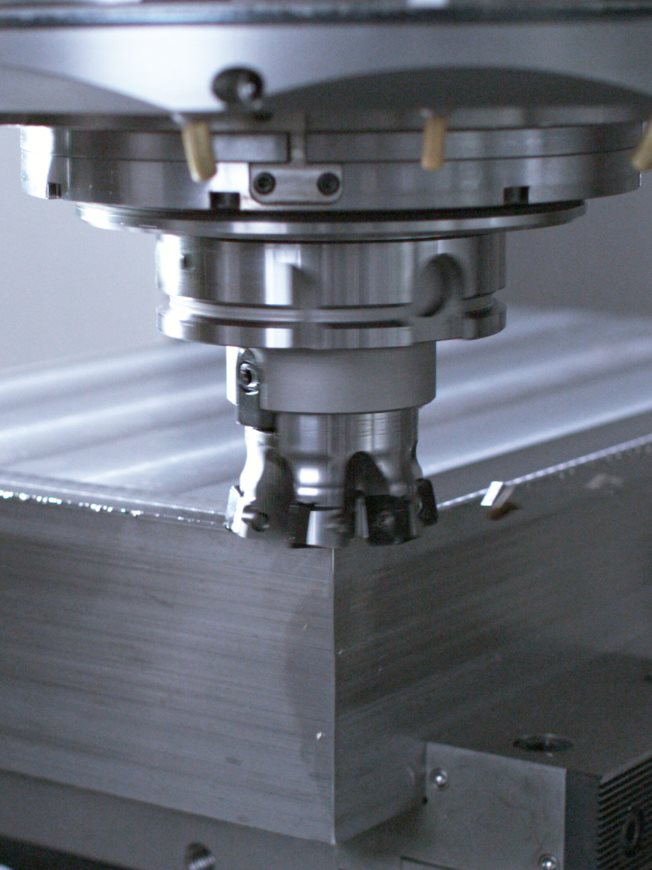

Milling tooling developments increase quality and productivity in the machining of orthopedic replacement components

R220.88 WITH SNMU INSERTS

TTP2050

DOUBLE QUATTROMILL™ 14

DOUBLE OCTOMILL™

DOUBLE QUATTROMILL™ 22

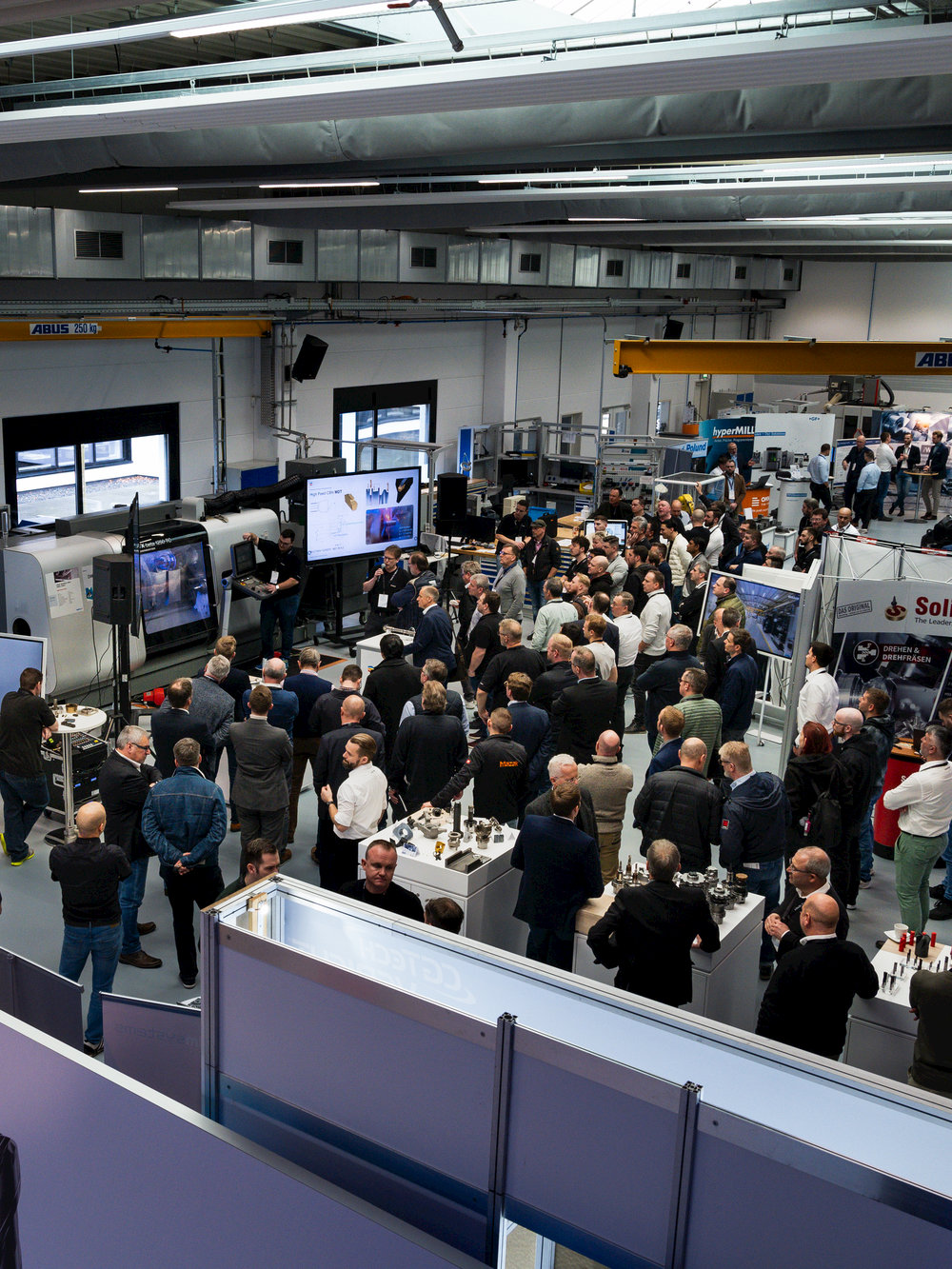

Inspiration Through Innovation 2024 Aerospace and Medical

Why a Strategic Partnership is the Perfect Medicine for Permedica

Dental Implant Components

Seco JS754 Stub Series Brings Versatility and Value When Milling Tough Materials

FEEDMAX -MS DRILL

Solid Support for Additive Manufacturing

Tibial Tray

Bearing Inserts

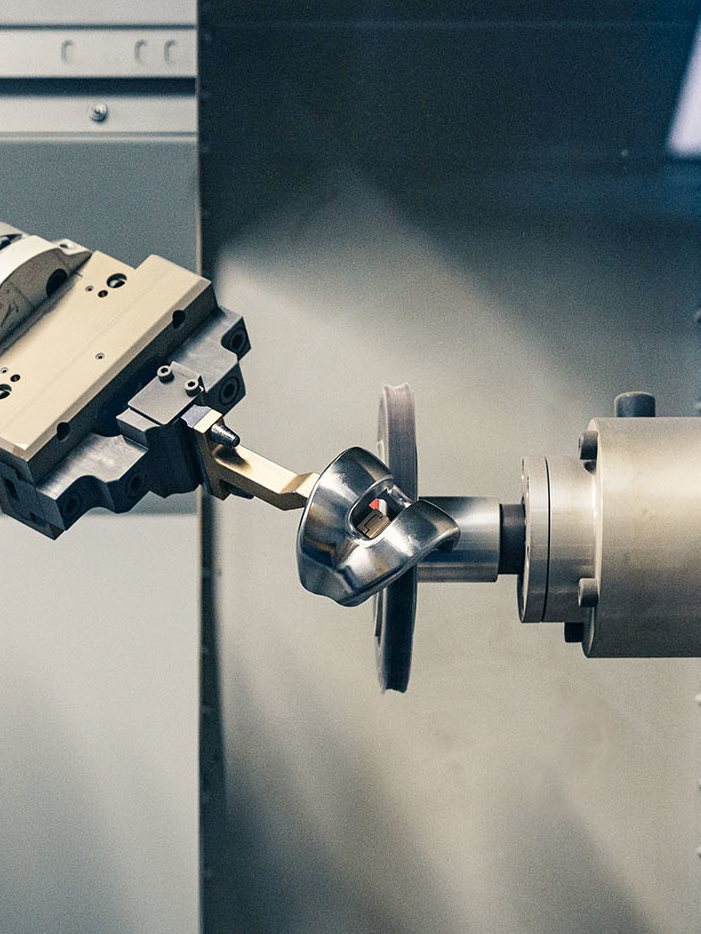

Knee replacement component machining demonstration

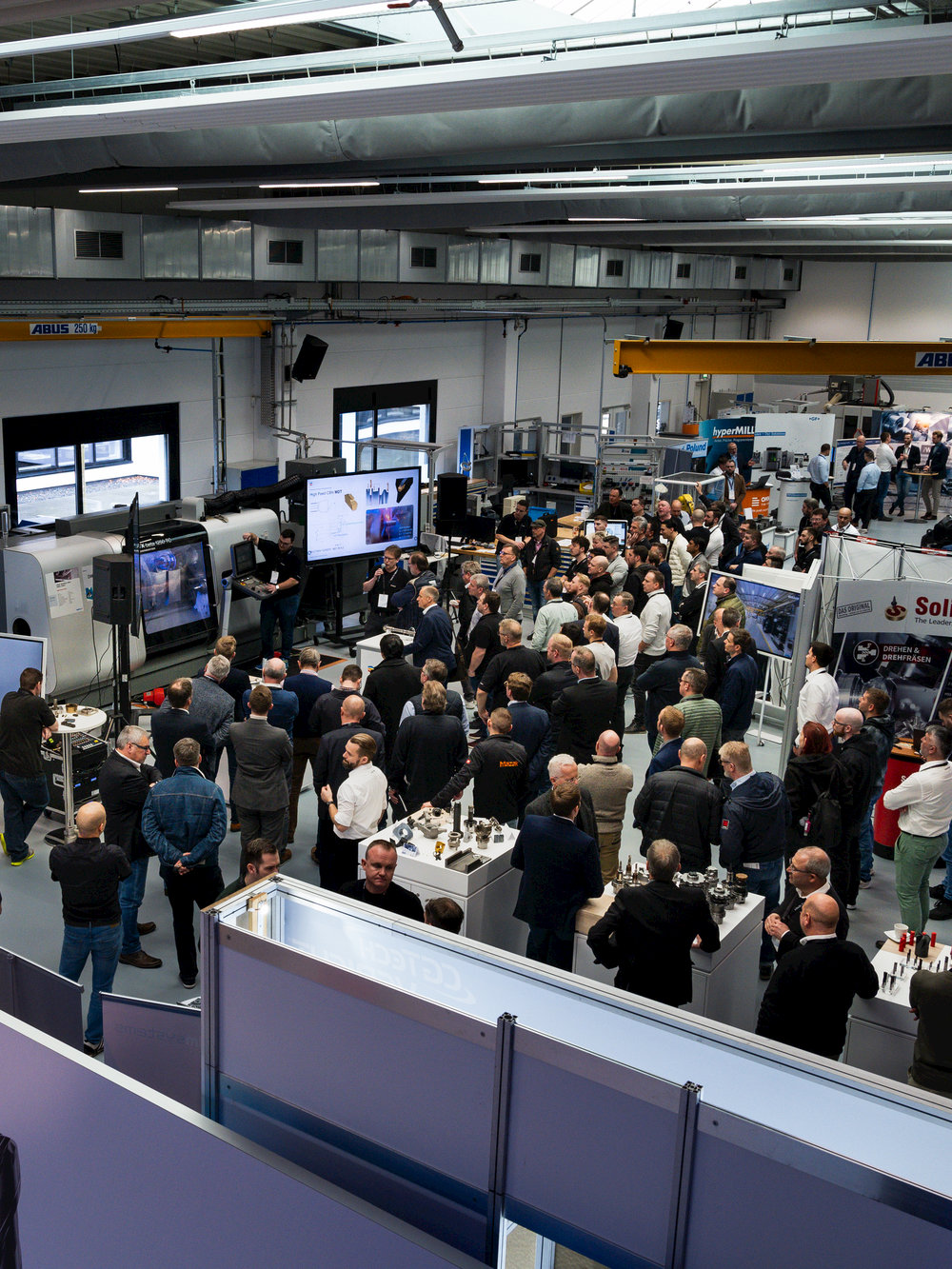

Inspiration Through Innovation

Overcome stainless steel supply challenges

The Rise of Composite Materials in Aerospace Manufacturing

5 Additive Manufacturing Trends Enhancing Production and Tooling

What does it take to engineer for tomorrow?

Manage Tool Wear with Stainless Steel

Balancing key factors in stainless steel machining

Superalloys and Titanium / ISO S

Stainless Steel / ISO M

How 3D Printing is Making its Mark in Medical

Inspiration Through Innovation 2024: Championing collaboration in the pursuit of manufacturing excellence

Expert Tips and Insights on Precision Medical Manufacturing | ITI Event