Increase stability, ensure quality and maximize cost performance

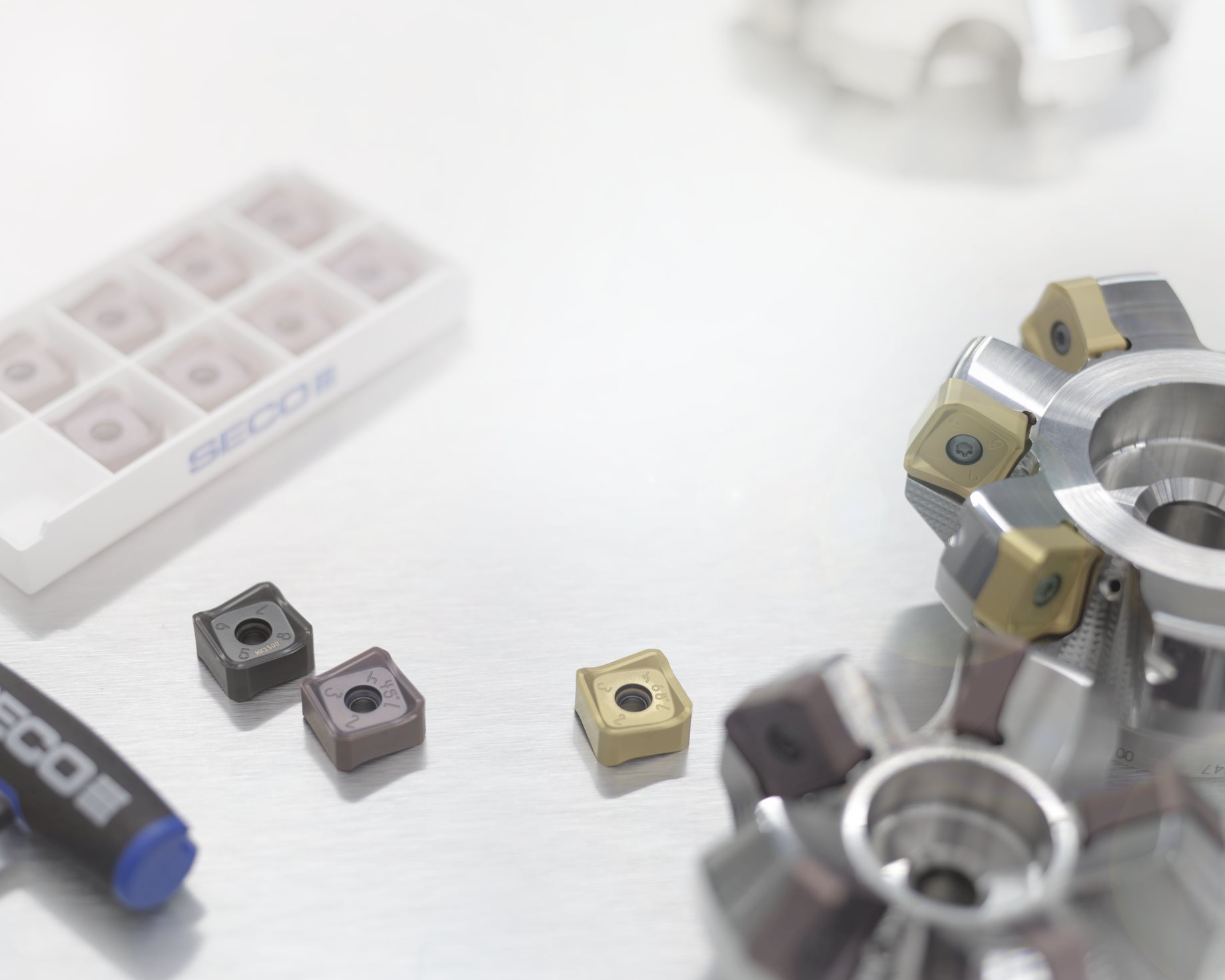

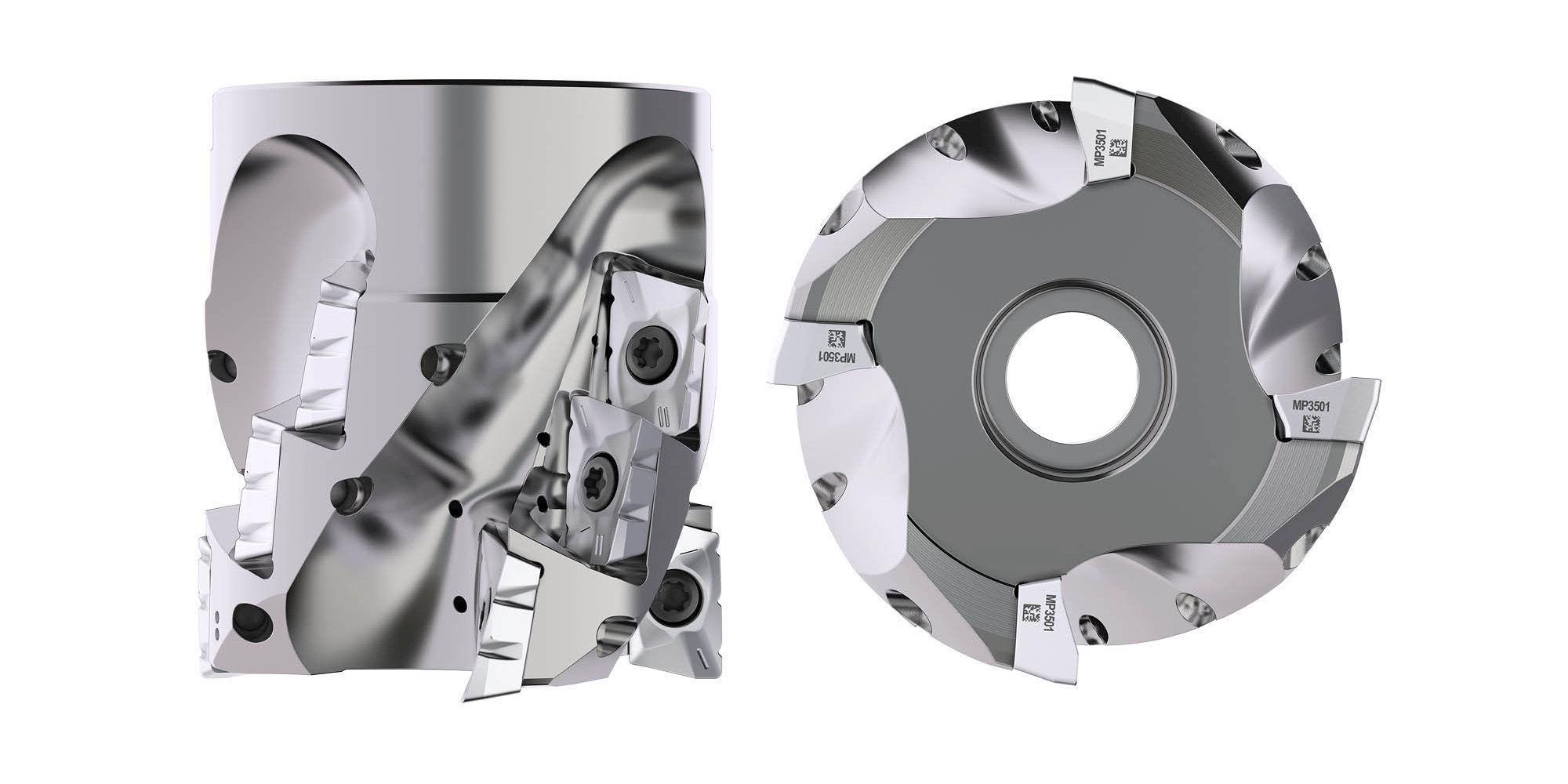

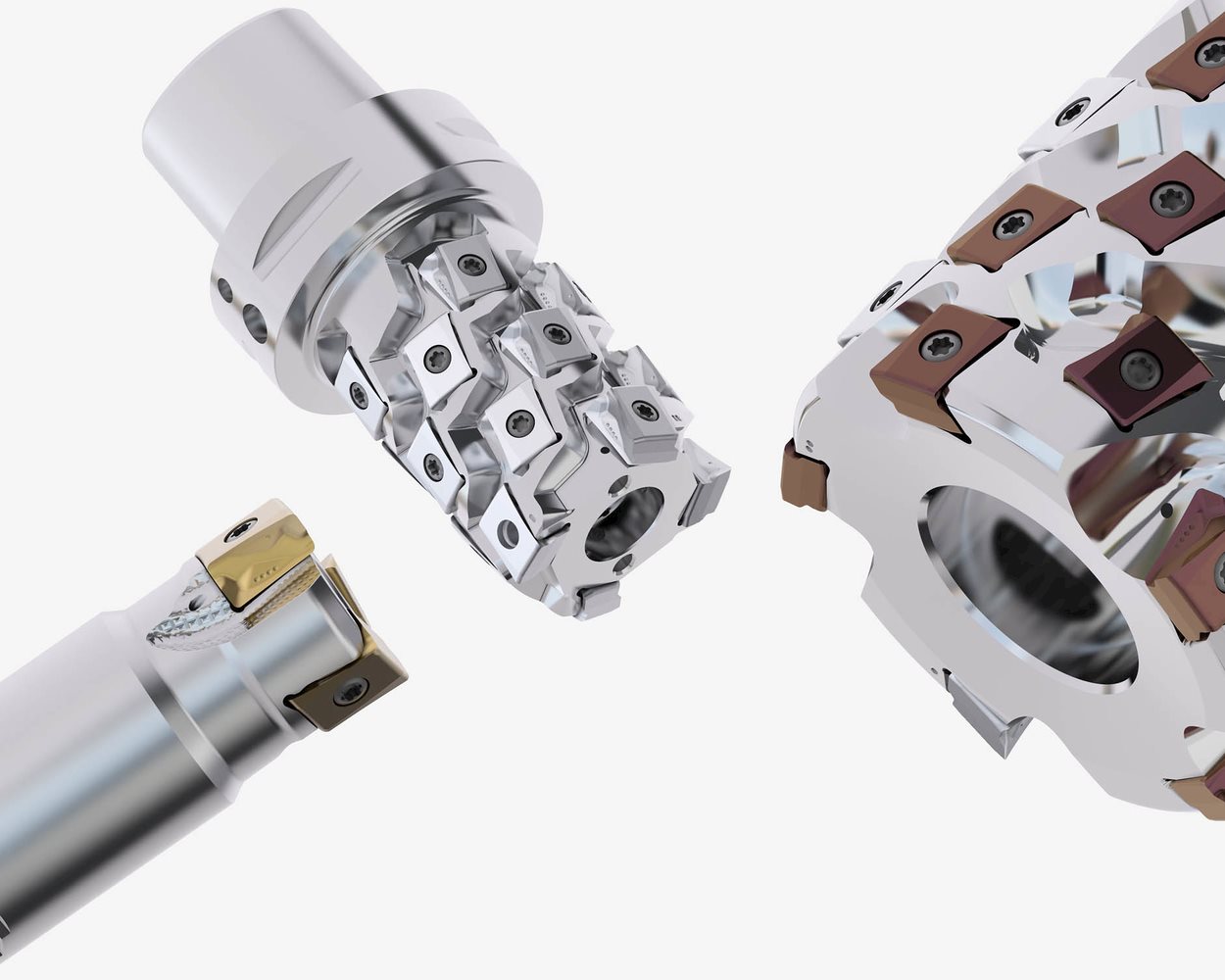

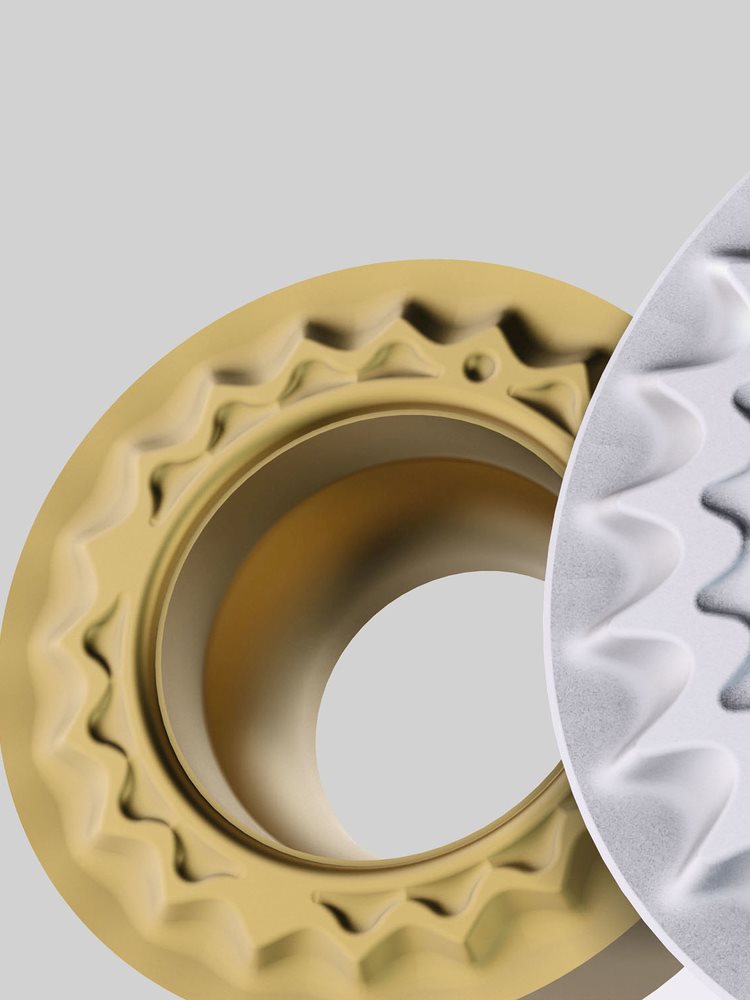

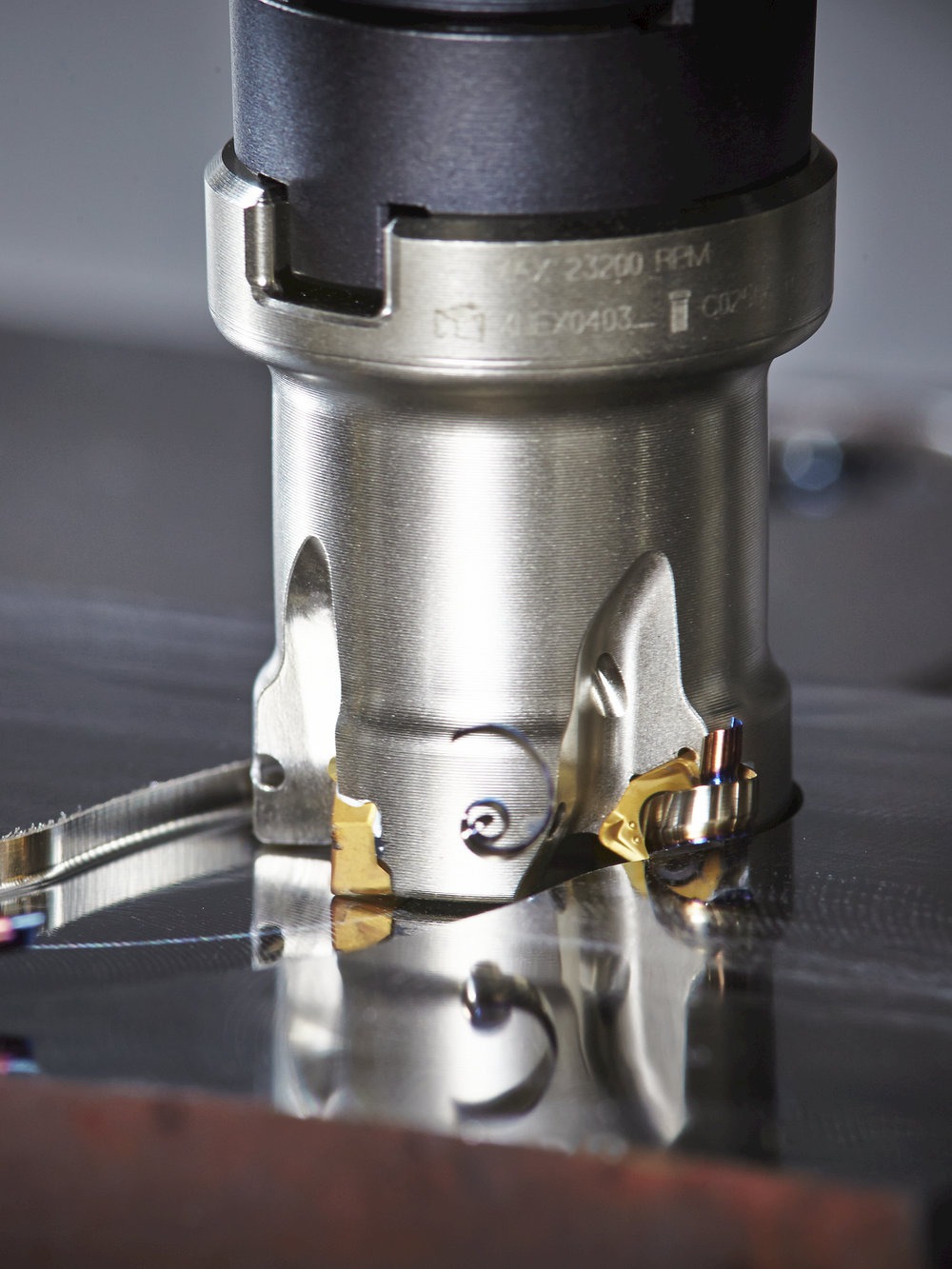

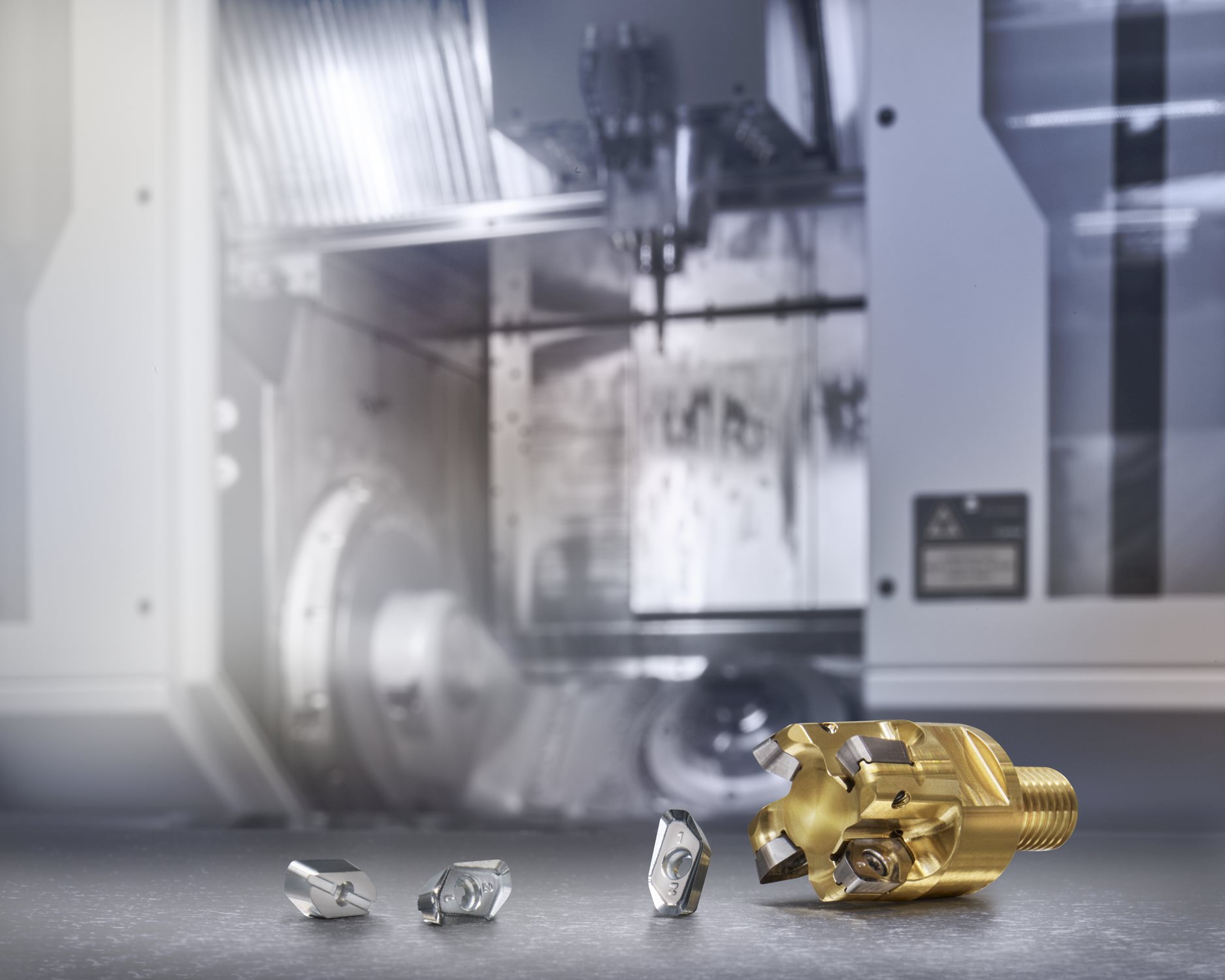

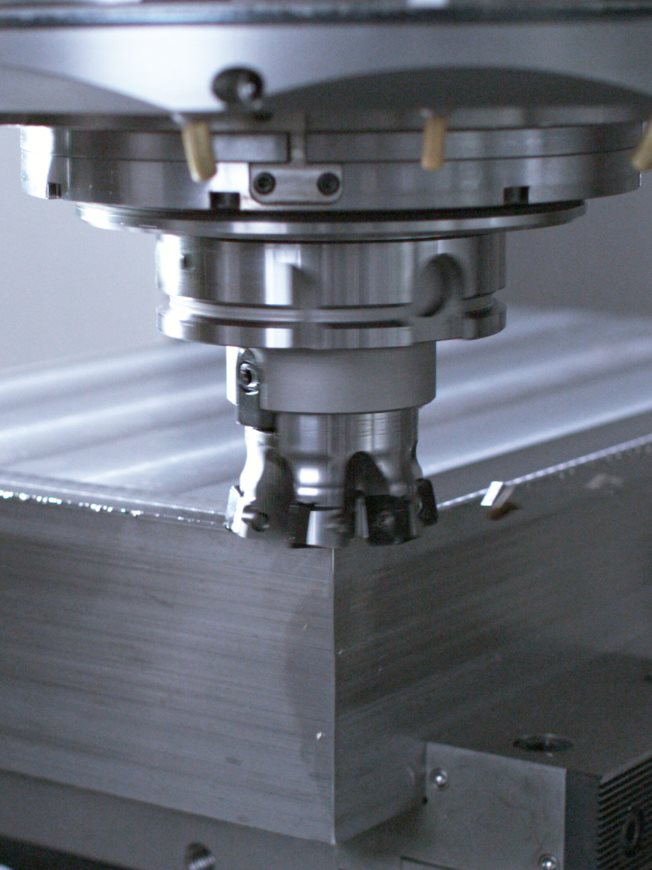

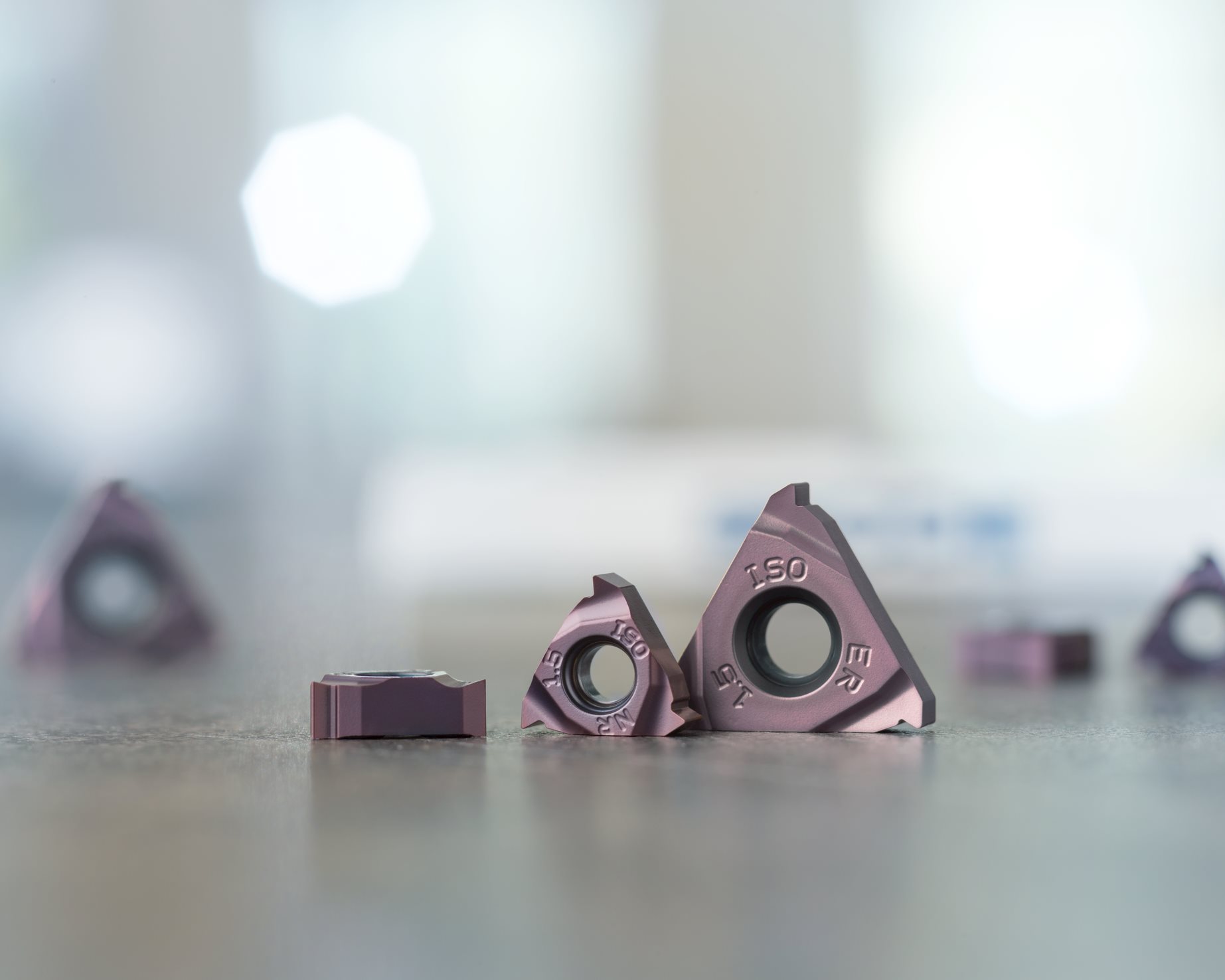

Turbo 12 & 18 chip splitter inserts reduce cutting forces and improve chip control. This results in higher process stability and part quality.Hard-to-reach part features can pose challenges. Even the most robust combinations of machine and tool can struggle with long overhangs. Available for both square shoulder and helical cutters, Turbo 12 & 18 chip splitter inserts put excellent results within your reach. They significantly reduce cutting forces to eliminate chatter, vibration and stress on your equipment.

Your challenge:

Ensure a smoother milling process.

The Seco solution:

Seco chip splitter inserts provide effective chip control to lower the stress on both the machine and cutting tool for improved milling conditions.

Your challenge:

Eliminate chatter and vibration when machining with long overhangs.

The Seco solution:

Seco chip splitter insert geometries minimize vibrations through reduced cutting forces.

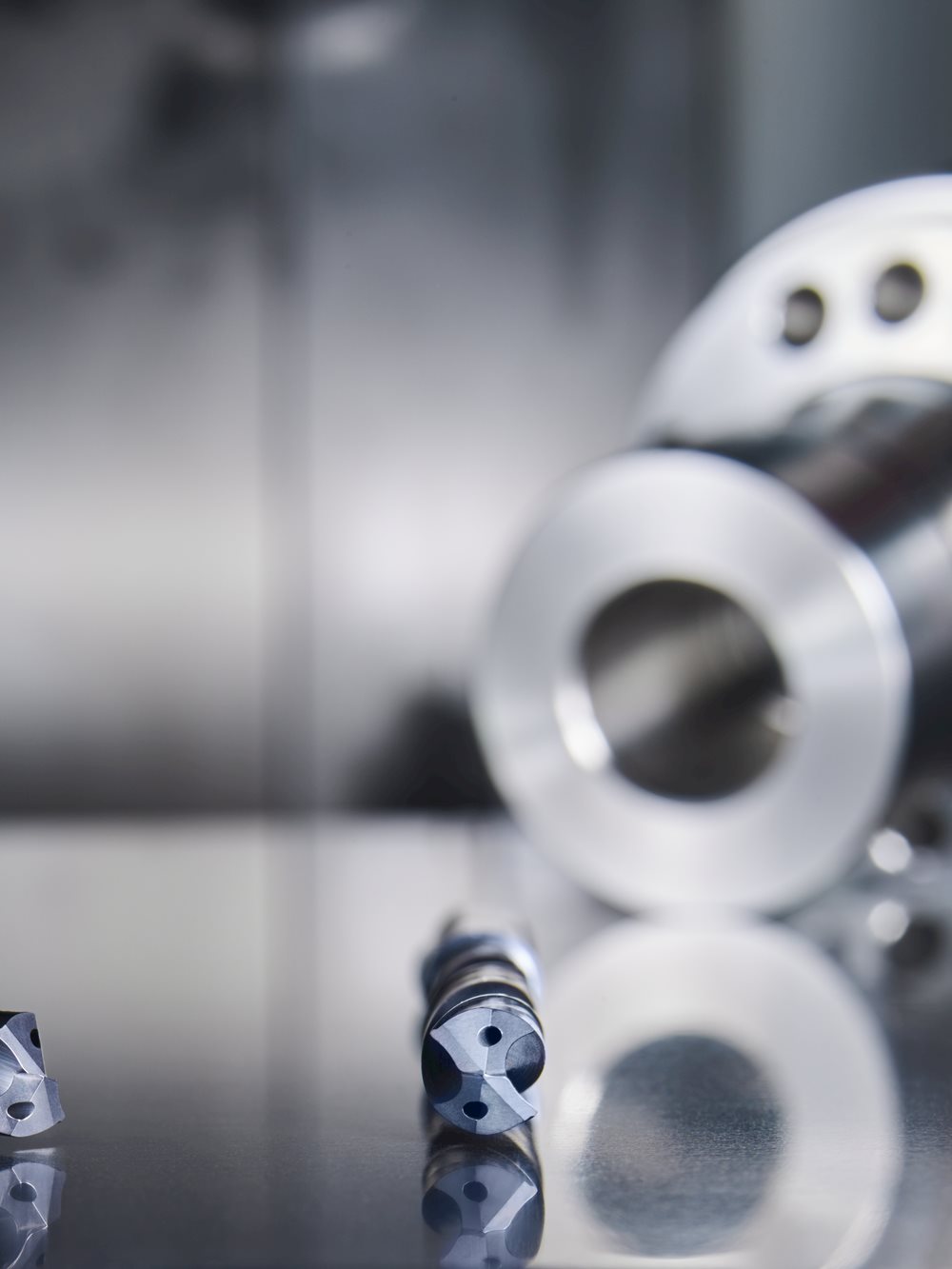

Put long chips behind you. Turbo 12 & 18 chip splitter inserts minimize chip size, allowing you to improve process security, tackle more challenging applications, eliminate safety hazards and more easily transfer waste for recycling.

Your challenge:

Increase the process security of milling operations.

The Seco solution:

Seco chip splitter inserts keep chips as small as possible to lessen the risk of chip jamming.

Your challenge:

Improve chip flow when machining deep pockets.

The Seco solution:

Seco chip splitter inserts effectively evacuate chips from deep pockets.

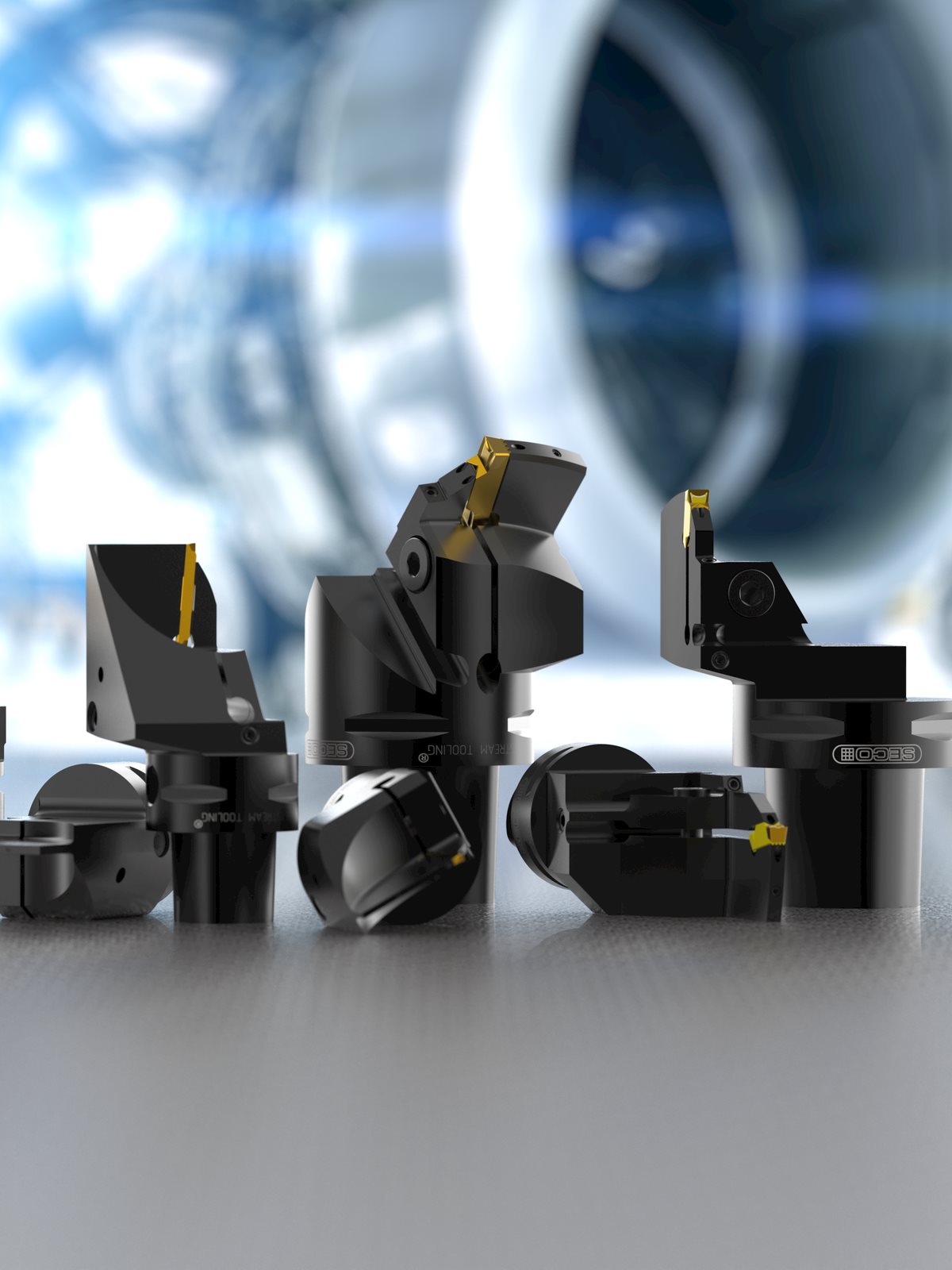

With stability comes predictability, a prerequisite for effective unattended machining. Seco Turbo 12 & 18 Chip splitter inserts help you attain secure, reliable processes that you can run lights out.

Your challenge:

Stabilize processes to allow for unmanned operation.

The Seco solution:

Seco chip splitter inserts boost process reliability and reduce the risk of unexpected disruptions.

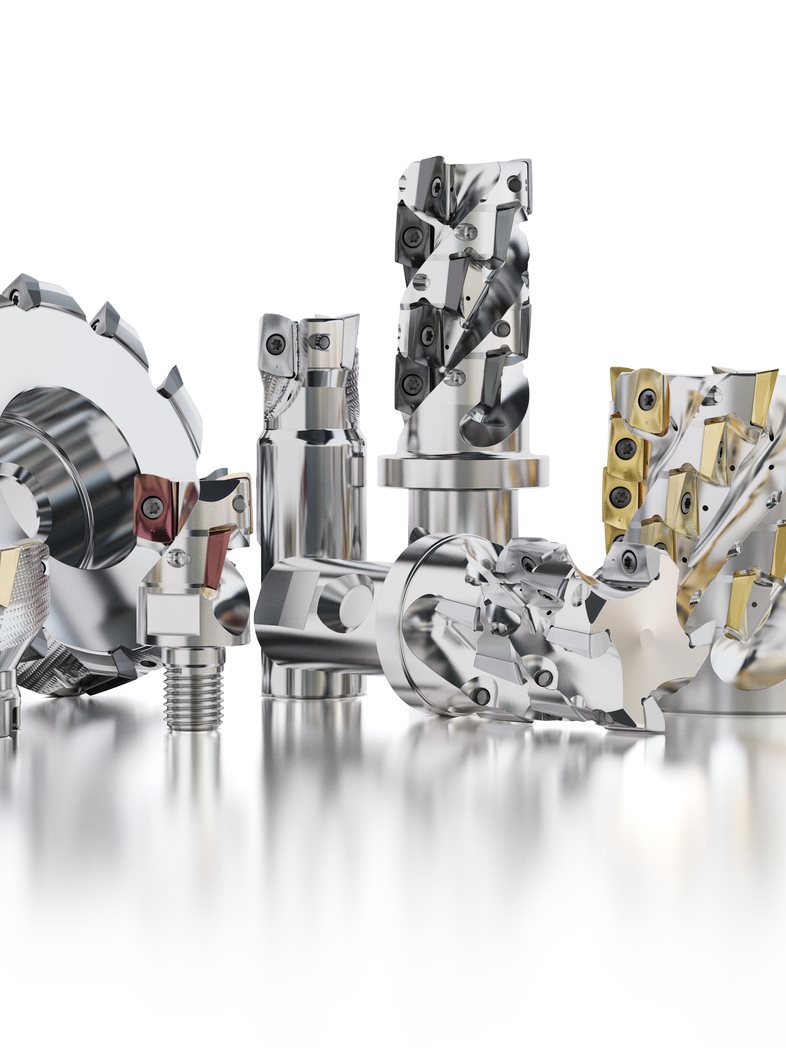

Discover the Turbo 12 product range

Discover the Turbo 18 product range

Related content

Seco News 2024.2

Seco Turbo Chip splitter: mounting instructions

Factsheet - Turbo 12 & 18 Chip Splitter Inserts

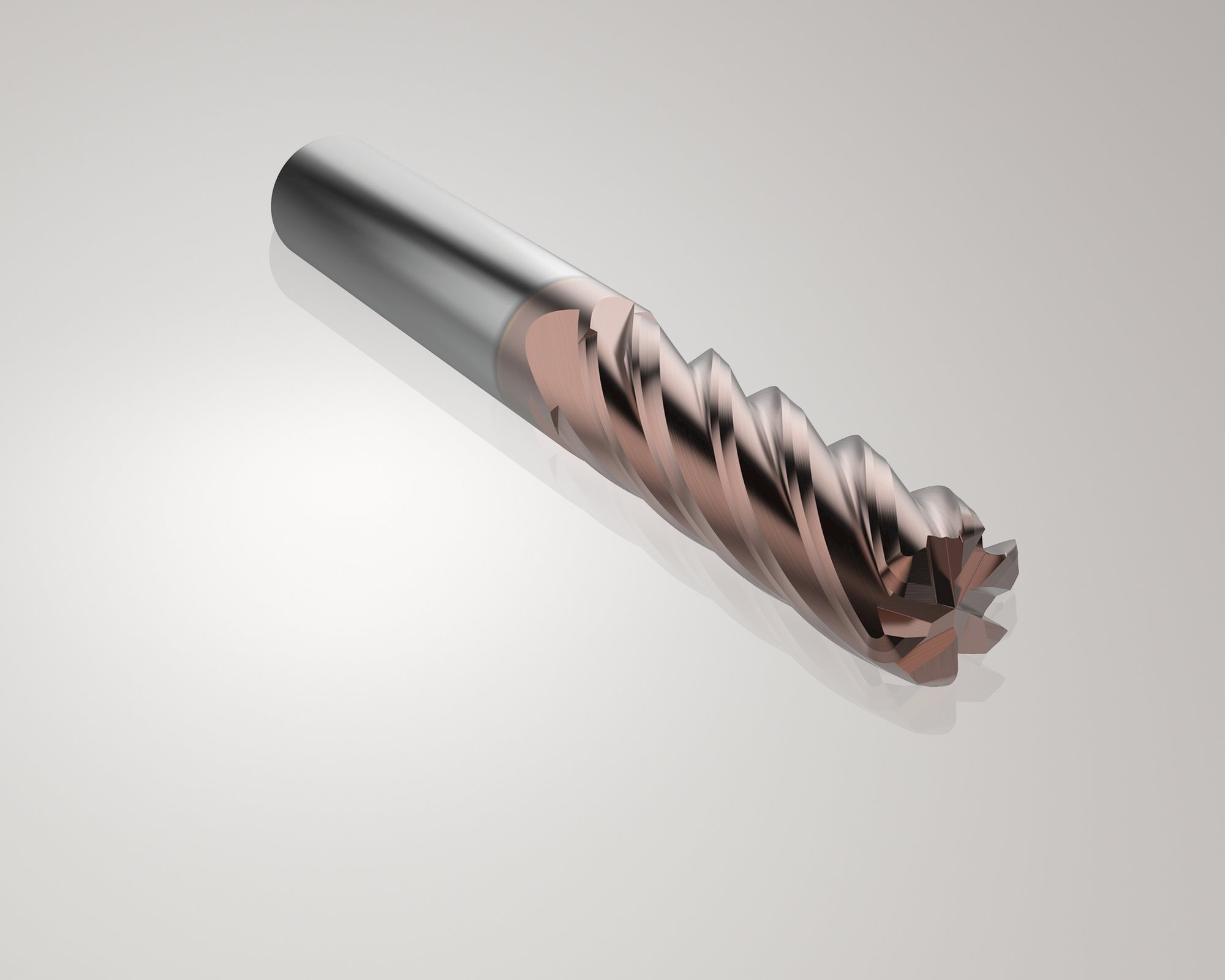

Seco C-Series General Purpose End Mills

Seco Helical LN4-11 Milling Cutter

JETI Toolholder for RCMT/RCGT Turning Inserts

Seco S43/S45/S46 Solid End Mills for Aluminum

Seco Machine Library

Seco X-Head Exchangeable End Mill System

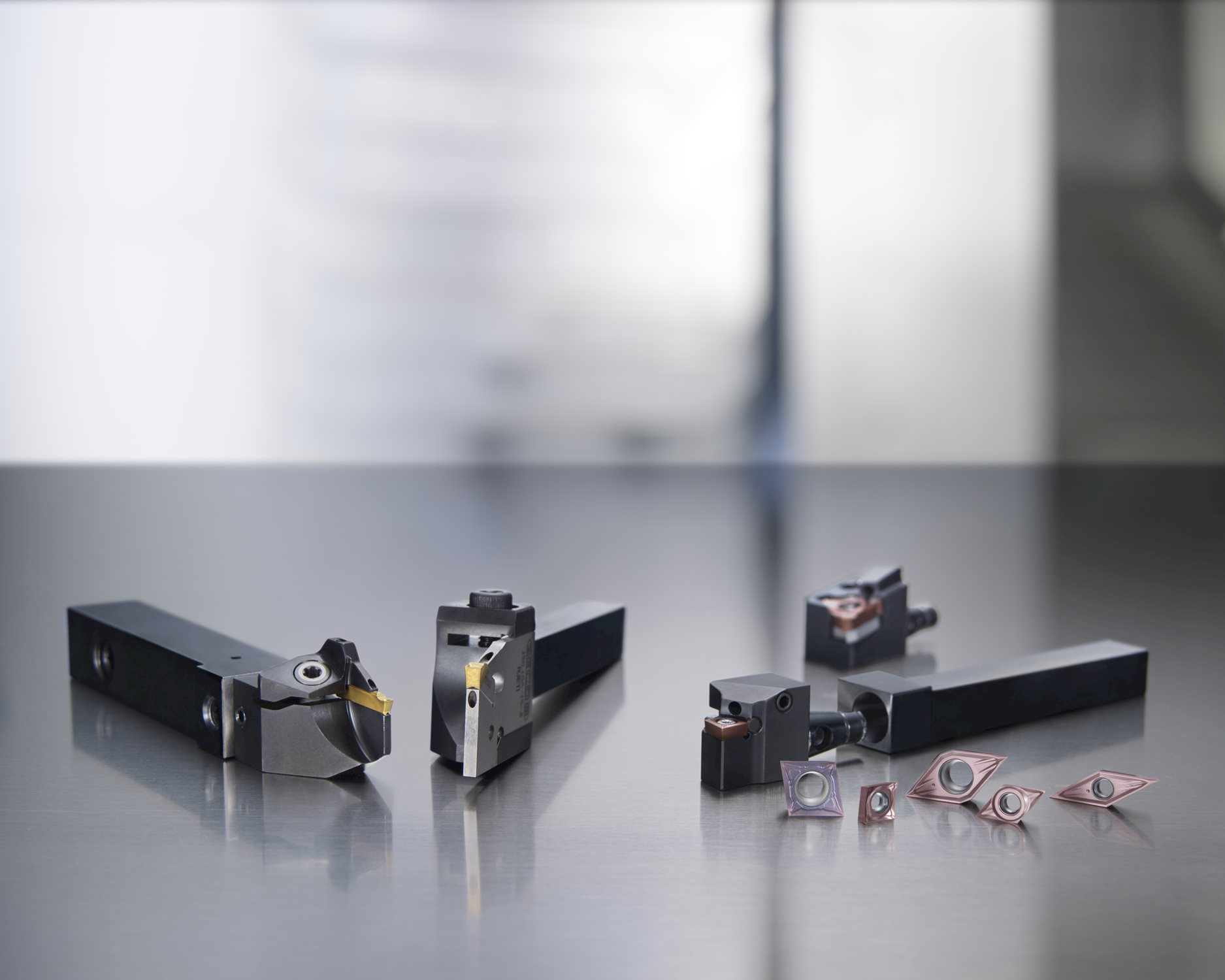

Seco X2 System for Small Part Machining

Seco Nanojet Reamers: reliable precision

Optimize Multi-Task Machining Coolant And Results

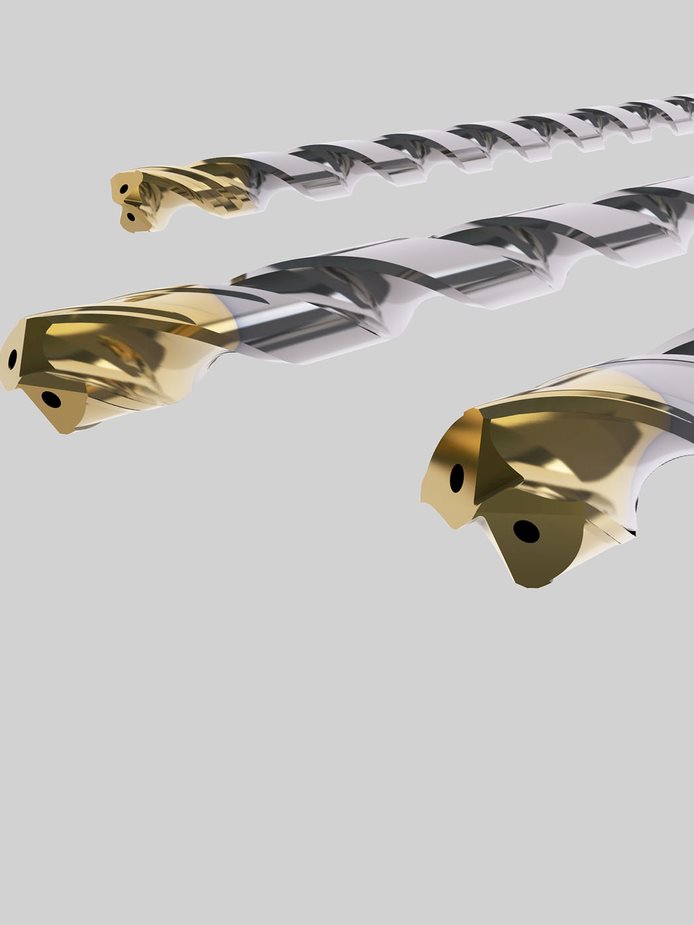

Seco X-Tra Long Solid Carbide Drills – 40xD-60xD

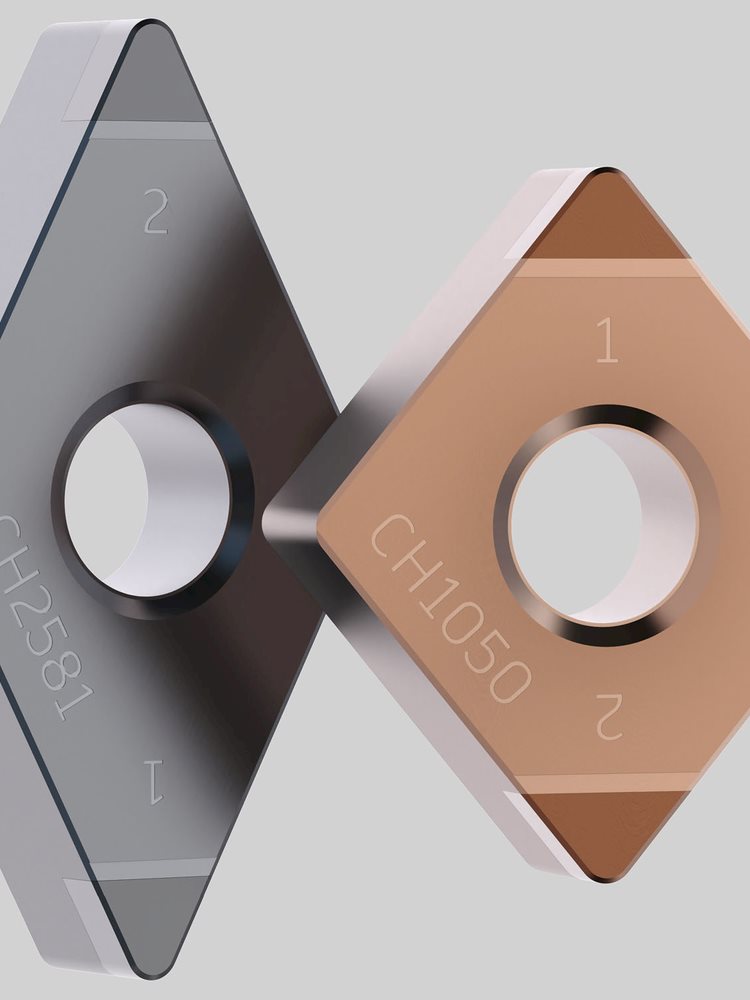

Seco CH1050/CH2581 PCBN Hard Part Turning Inserts

JS720 Solid End Mills addition

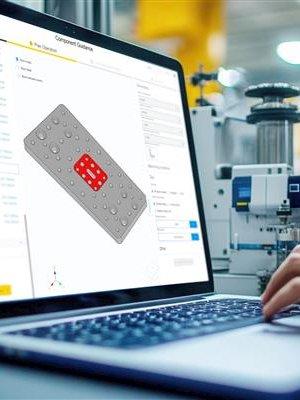

Seco Digital Tool Assembly: quick, accurate data

Easy setup with Seco Digital Axial Boring Heads

JH730 Solid End Mills addition

Square T4-12 Upgrades

Universal Drills

MF2 Chipbreaker on Round RCMT/RCGT Inserts

TURBO 16 SQUARE SHOULDER MILLING CUTTERS

Chip splitter inserts provide effective chip control for milling stability

Turbo 12 & 18 Chip Splitter Inserts Mounting - animation

Seco Component Guidance

Versatile Round 20 Inserts Increase Tool Life

Seco Octomill™ 06: Flexible, Robust Tooling

Seco Stabilizer Series: Unmatched Metal Removal

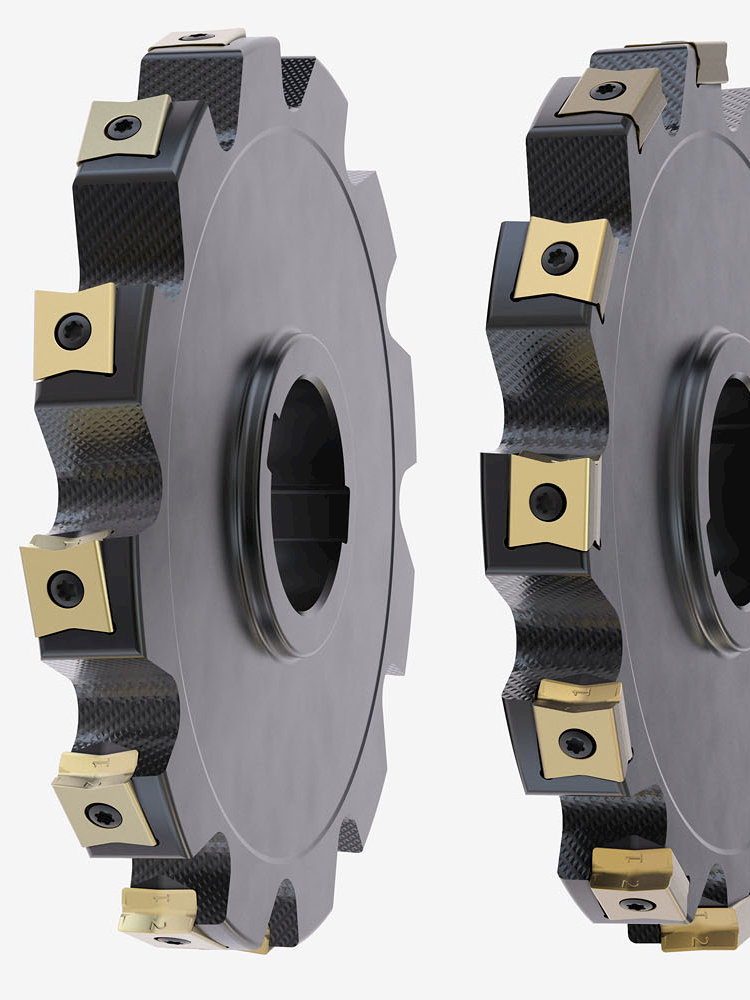

335.14 Disc Milling Cutter extension

Seco T30 Taps: a versatile universal geometry

Seco 335.98 Disc Milling Cutter system

Seco My Design: Design custom tools

Seco T35 Taps: match Tooling to Materials

Guillaume Bourderon appointed Sales Unit Market Manager France

JETI CONVERSION GROOVING AND PARTING-OFF

Steadyline® ø25mm (1”) series

New MP Milling Grades

Turbo 10

Unleash your drilling potential

Seco Tools Introduces Double Turbo Square Shoulder Mills and Inserts

JETI ISO Toolholder range extension

JETI conversion Grooving and Parting-off Capto

JM100 MINI END MILLS

Modular QC (quick-change) toolholder for small part machining

SECO-CAPTO TOOLHOLDERS & CASSETTES FOR ADVANCED MATERIAL

XP08 ALUMINIUM ROUTER

RANGE EXTENSION OF SHELL MILL HOLDERS, SMALL FACE & SIDE LOCK HOLDERS IMPROVEMENTS

COMBIMASTER™ M20

EASYSHRINK EVO

UNIVERSAL DRILLS 8XD AND 12XD

SECO ROUND 10 AND 16 COPY MILLING INSERTS

DOUBLE TURBO 16

High Feed square cut size 14 insert

ISO K THREADING TAPS

R220.88 WITH SNMU INSERTS

TTP2050

DOUBLE QUATTROMILL™ 14

DOUBLE OCTOMILL™

DOUBLE QUATTROMILL™ 22