Improve Tapping in large production runs and specific materials

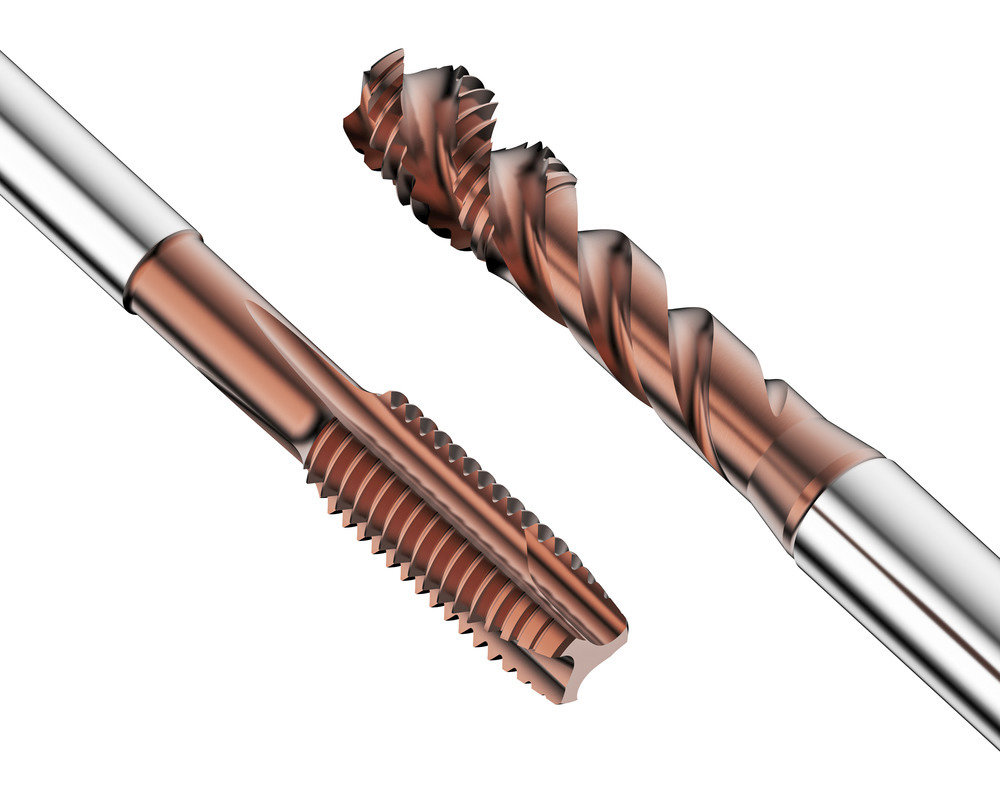

Save on high-volume tapping costs. Seco T35 taps are optimized for specific material groups.

Seco T35-P taps boost performance in alloyed steels with an optimized geometry and special TiAlSiN coating.

Seco T35-P taps boost performance in alloyed steels with an optimized geometry and special TiAlSiN coating.

Applied via HiPIMS technology, the TiAlSiN coating provides exceptional smoothness, hardness and cracking resistance.

Your Challenge:

To increase tool life and reliability in alloyed steels with Rm 800-1200 MPa.

The Seco Solution:

Seco T35-P taps are made of HSSE-PM, and use a special geometry and TiAISiN coating to minimize tool wear with alloyed steels.

Extend tool life and eliminate miscut threads with the special geometry of Seco T35-K taps.

Extend tool life and eliminate miscut threads with the special geometry of Seco T35-K taps.

A high-performance HiPIMS-applied TiAlSiN coating further enhances tool life and part quality.

Your Challenge:

You want to increase tool life and reliability in short-chip cast materials such as abrasive cast iron.

The Seco Solution:

Seco T35-K taps are made of HSSE-PM, and use a special geometry and a TiAISiN coating to minimize tool wear with abrasive cast iron.

Your Challenge:

How do you avoid miscut threads during tapping operations.

The Seco Solution:

Seco T35-K taps use a special geometry to eliminate miscut threads when tapping abrasive cast iron.

Large, polished flutes and a specialized geometry give Seco T35-N taps excellent chip formation and evacuation in aluminum.

Large, polished flutes and a specialized geometry give Seco T35-N taps excellent chip formation and evacuation in aluminum.

Eliminate long, stringy chips and improve part quality, process security and tool life.

Your Challenge:

You want to increase tapping reliability and thread quality in aluminum parts.

The Seco Solution:

Seco T35-N taps incorporate large, smooth flutes for optimal chip formation and evacuation in soft aluminum parts.

Seco T35-H threading taps excel in tough materials. Their HSSE-PM material and TiAlSiN coating achieve strong wear resistance in hard steels, cast irons and cast aluminums. This relative flexibility allows you to handle materials of 30 – 45 HRC with a single tool.

Your challenge:

Extend tap life in tough and abrasive materials.

The Seco solution:

Achieve long tool life in materials of 30 – 45 HRC thanks to HSSE-PM material and TiAlSiN coating of Seco T35-H taps.

Your challenge:

Minimize tool inventory.

The Seco solution:

Reduce inventory by tapping hard steels, cast irons and cast aluminums with a single T35-H tap.

Long, stringy chips pose a risk to your process and your operators. Seco T35-H threading taps incorporate a helix angle that breaks tough materials into small chips. Relatively large tool flutes then provide efficient evacuation.

Your challenge:

Control the generation of bird-nest chips when tapping blind holes in tough and abrasive materials.

The Seco solution:

Create small, manageable chips with the 15-degree helix angle on T35-H taps.

Your challenge:

Effectively evacuate chips when using taps on a turning machine for blind holes

The Seco solution:

Larger flutes and optional internal coolant allow T35-H taps to provide optimum chip evacuation.

For optimal usage, discover our range of Tapping Chucks

Inline Content - Sugar Form

Sugar Form url - https://info.secotools.com/acton/media/45194/t35-taps

Frame height - 550 px