Seco and Mastercam: How Accelerated Finishing Tools Enhance Surface Finishes and Save Time

Accelerated finishing tools rely on path-intensive programming routines. To combine optimized tooling with equally optimized programming, Seco partnered with CAM provider Mastercam to leverage its Unified Multiaxis Toolpath software, a sophisticated CAM feature that simplifies accelerated finishing.Production optimization reduces the amount of time required to resolve unexpected machining problems, which can occupy up to 25% of the production cycle. To create ideal surface finishes, manufacturers need to reduce the amount of excess material left between the passes of a toolpath, also called the cusp height or scallop height.

Traditional ball endmills provide one solution, but they require shorter toolpath stepovers and often involve longer cycle times. To improve surface finishes and decrease cycle times by 20%-90% compared to traditional ball endmills, Seco accelerated finishing tools – also called barrel tools or circle segment end mills – use a large profile radius that reduces cusp height.

Accelerated finishing tools rely on path-intensive programming routines. To combine optimized tooling with equally optimized programming, Seco partnered with CAM provider Mastercam to leverage its Unified Multiaxis Toolpath software, a sophisticated CAM feature that simplifies accelerated finishing.

Accelerated finishing provides results for shops that need to:

Achieve demanding surface finishes

Reduce cycle times and cusp heights

Improve tool life

Make better use of cutting edges

Optimize machining results with barrel, lens, lens-barrel, drop and taper barrel tools

Maximize flute contact on each machining pass

The Mastercam Tech Exchange informational site supports Seco drop shape, taper shape, and application-targeted medical accelerated finishing tools with sample files, tool libraries, post-processors, and more. To make the combination of Seco accelerated finishing tools and Mastercam programming effective for a wide variety of shops, Seco STEP training also includes a free online training course on Solid Milling Barrel Tools.

Seco Tools and Mastercam have demonstrated the effectiveness of this partnership on several recent projects that rely on accelerated finishing.

Material: 6061-T6 Aluminum

Machine: Haas UMC-500SS

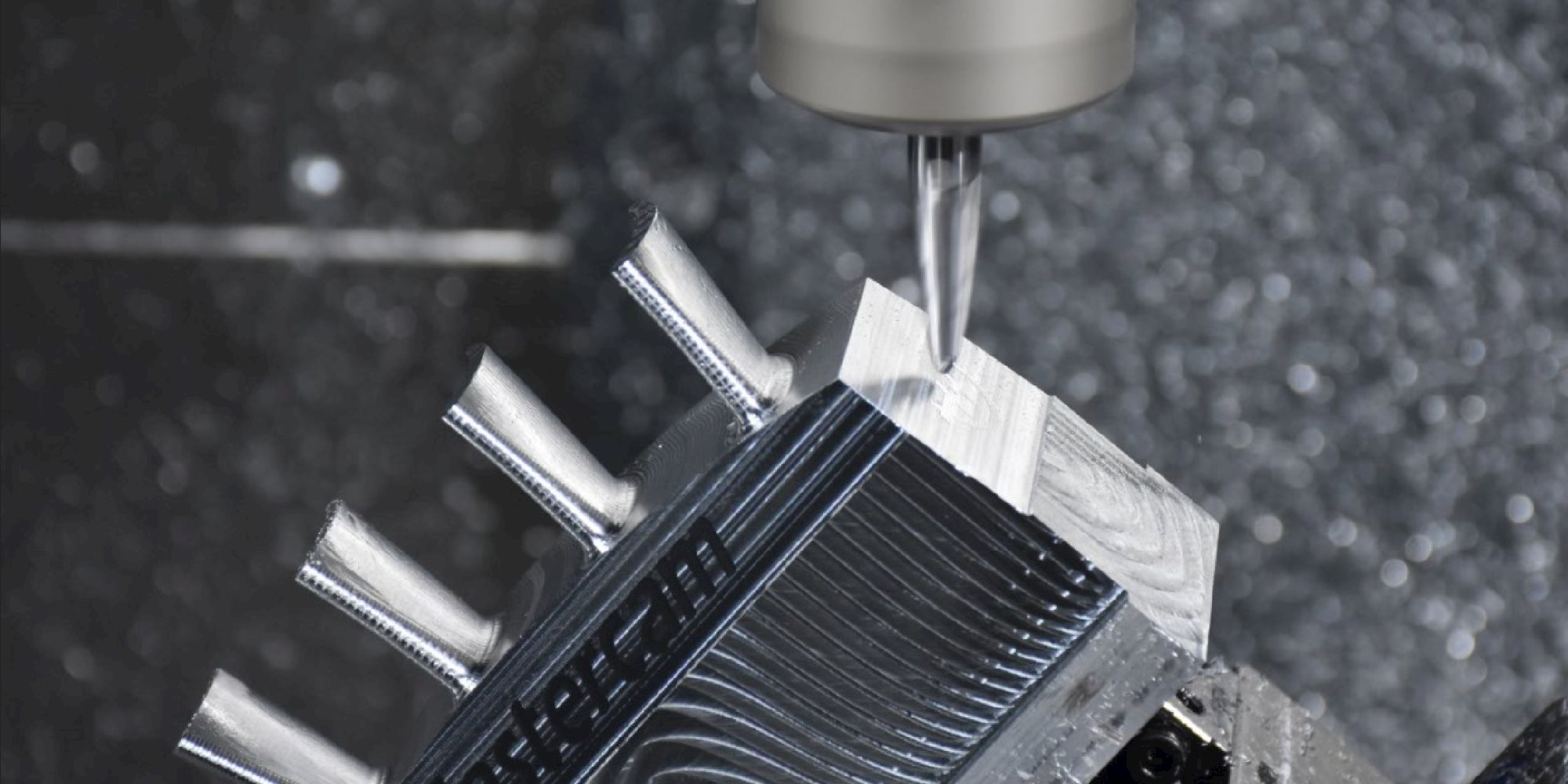

Accelerated finishing tool: Customized Seco Barrel Tool from JH7 ranges

The collaboration came to life for attendees of the 2023 Haas Factory Outlet Demo Day in Pittsburgh through the live creation of an aluminum blisk (pictured) machined by a Seco Barrel. While the flute geometry of Seco's barrel tools was originally developed for stainless steel and superalloys, Seco expanded on the design to meet the needs of machining aluminum. By customizing the flute count and geometry, aluminum chips are directed away from the cutting edge during a heavy cut. The tailored design produced improved surface finishes in aluminum and enabled more aggressive cutting parameters.

In addition to flute geometry, Seco also can specialize tool profiles to produce more reach, an alternate tangency angle or a different root fillet to optimize performance for specific applications. To use these innovative customizations, shops can type dimensions into Mastercam’s Tool Wizard to take advantage of parametric tool definitions and create matching custom geometry. Mastercam automatically generates a new tool profile with each change in tool parameters.

Material: 4140 Steel

Machine: Kitamura Medcenter5AX

Accelerated finishing tool: Seco Barrel JH7 series

In addition, Seco and Mastercam know-how converged at NEXT Industries’ August open house event to showcase a side-by-side demonstration of a medical clip.

Accelerated finishing was applied to half of the clip’s surface area and a traditional ball endmill used on the other half. Each tool was programmed with its recommended speeds and feeds, but the toolpath stepover was set to leave a constant 0.0002" (0.005 mm) cusp height. This produced a stepover of 0.02" (0.5 mm) for the 12mm Ball-nose Endmill and 0.09" (2.3 mm) for the 12mm Drop Shape Tool.

Both strategies produced outstanding surface finishes. Time and the opportunity to save 6 minutes per part was the true differentiator. The ball endmill’s cycle time ran 8 minutes and 30 seconds and Seco/Mastercam’s accelerated finishing tool covered the same amount of surface area in only 2 minutes and 30 seconds.

Shops that want to gain back time by using accelerated finishing tools can visit the Mastercam Tech Exchange for Seco tool lists, setup sheets, and fully programmed Mastercam files.

Seco is proud to include Mastercam as part of the company’s global network of partners. In collaboration with the network, Seco focuses on individual challenges and develops new solutions to optimize each customer's manufacturing process. Visit the Seco Innovation Hub to learn more.

Inline Content - Survey

Current code - 5fce8e61489f3034e74adc64