What is P material group?

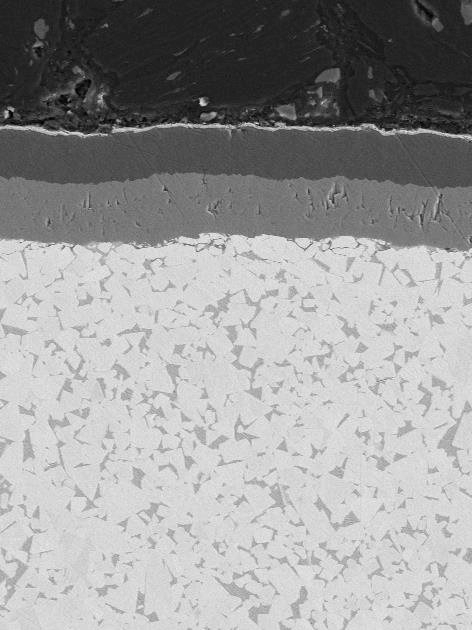

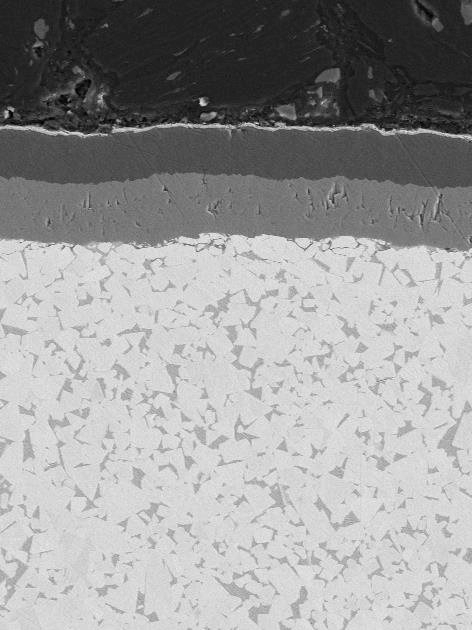

The ISO P classification of workpiece materials includes the metals generally referred to as steels.Steel is defined as an alloy consisting of iron, Fe, and carbon, C, with carbon content less than 2% by weight. In addition, the properties of steel can be modified for different purposes by alloying with other metallic elements such as Chromium (Cr), Nickel (Ni), and Molybdenium (Mo) etc. for example for increasing corrosion resistance.

The ISO P classification of workpiece materials includes the metals generally referred to as steels. While steels don’t present obvious machining challenges on the level of materials such as heat-resistant aerospace alloys used in aerospace applications, steel alloys and irons are the workpiece materials most widely applied across all industries. Such wide use has spawned the development of a large selection of steel alloys with differing physical properties that generate a variety of metal cutting performance issues. Those issues, in addition to economic considerations born of high-volume production demands, make machining of ISO P steels a significant challenge for parts manufacturers as well as the makers of the tools used to machine them.

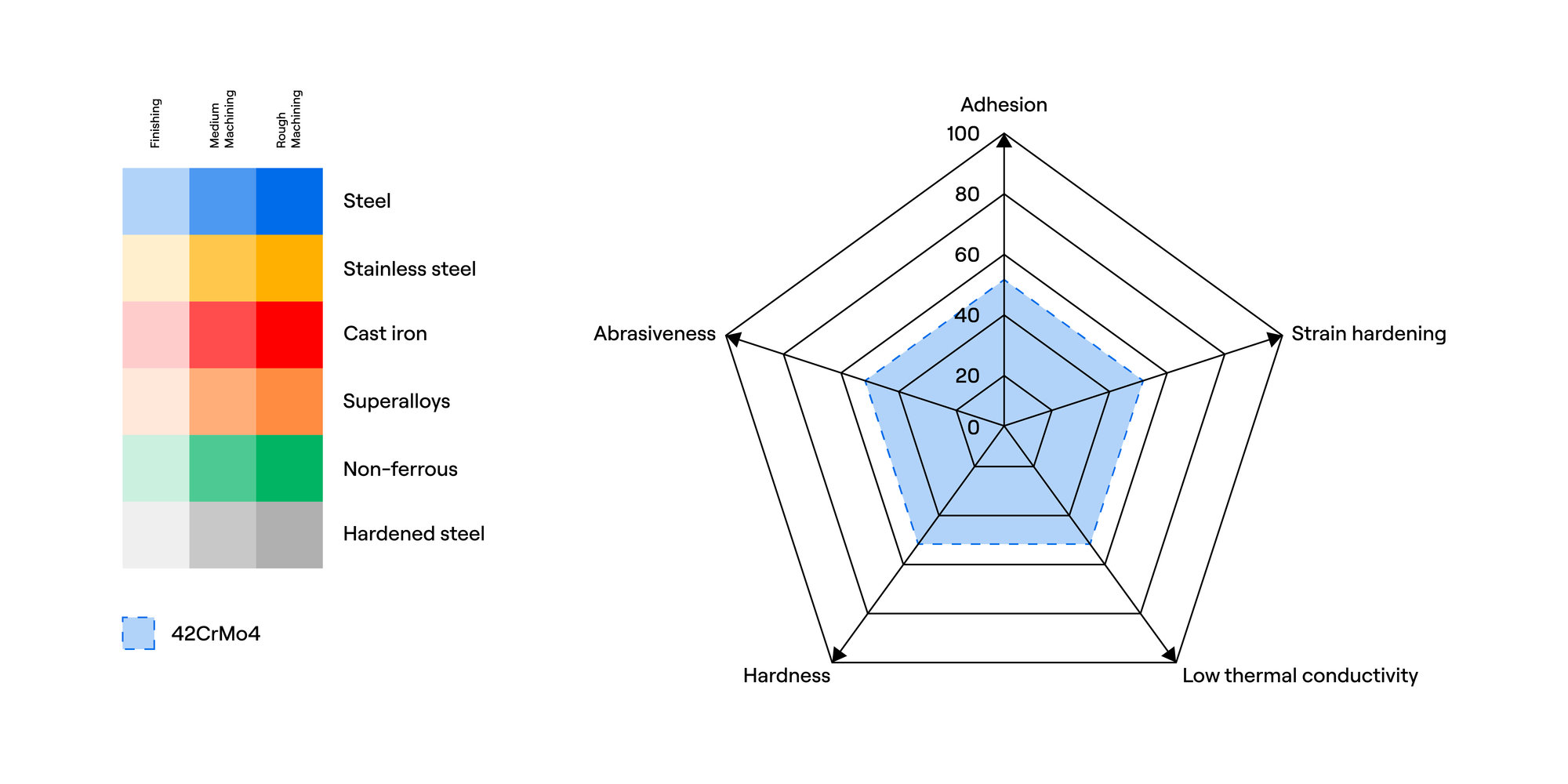

Seco classifies the machinability of materials based on 5 important properties: abrasiveness, ductility, strain hardening, thermal conductivity and hardness.

Do you want to know more about this material?

Discover our STEP program

You already have an application in mind for this material?

Find the right tool within a minute with Suggest!

Basic guidelines for machining ISO P materials, e.g. steel machining:

- High mechanical loads are your main concern (leading to flank and crater wear)

- Use big depth of cut and high feed

- Use cutting speed to balance tool life with economic considerations on the process

- Use versatile carbide grades and appropriate cutting geometry to balance with selected feed

- Emulsion (4% – 6%) cooling is advised, JETSTREAM cooling gives good results

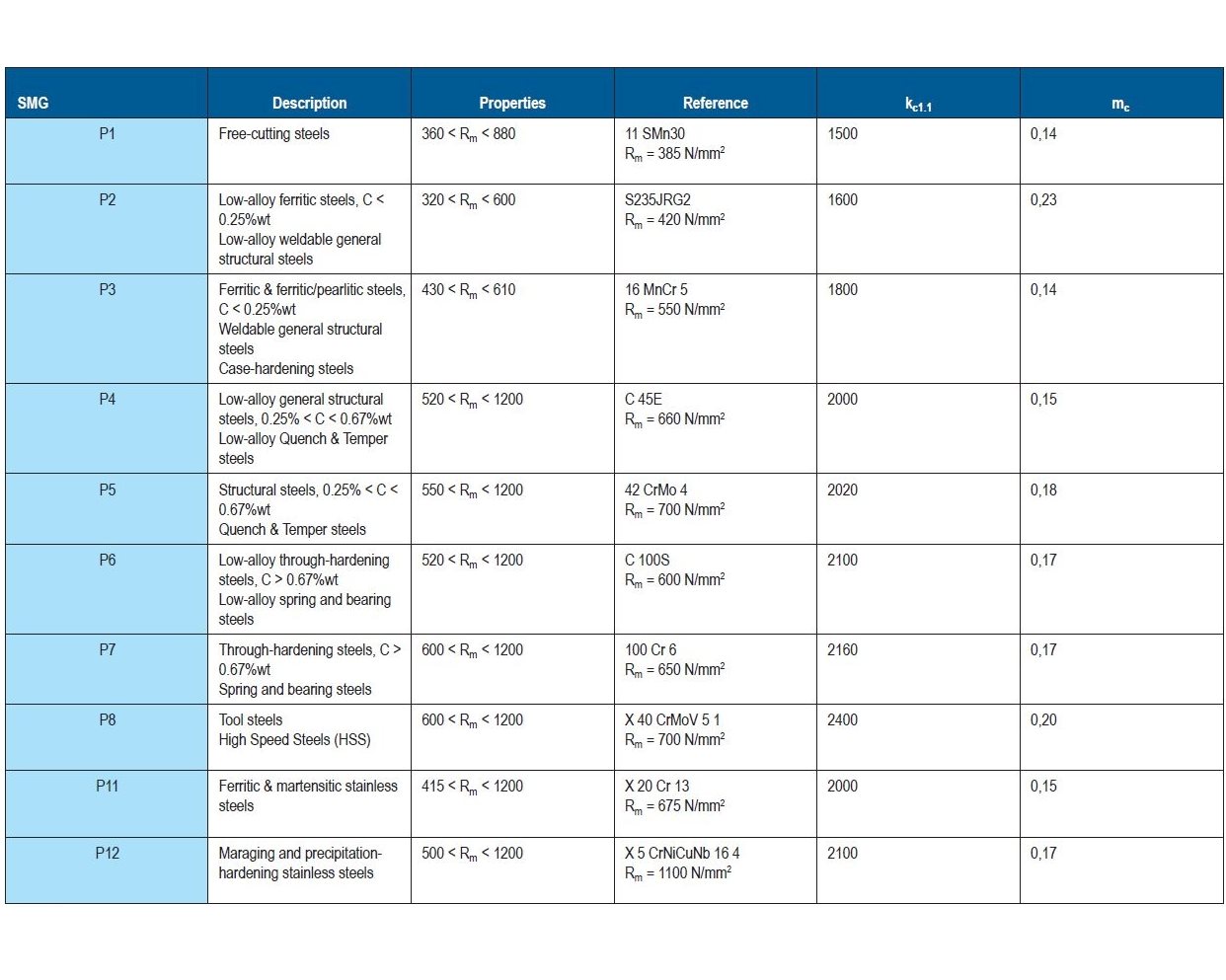

ISO P Tab extract

Inline Content - Survey

Current code - 5fce8e61489f3034e74adc64

Related content

Steel / ISO P

Steel / ISO P

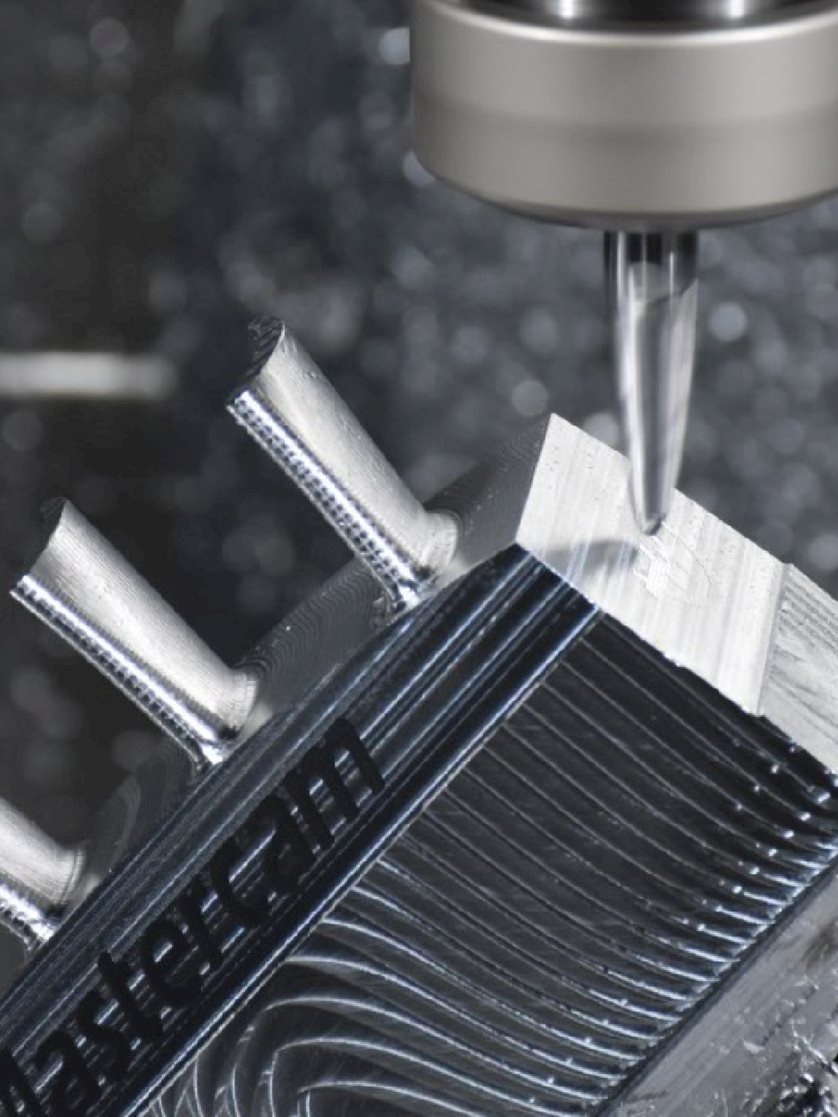

Seco and Mastercam: How Accelerated Finishing Tools Enhance Surface Finishes and Save Time

New Insert Grade MP2050

Seco goes above and beyond drilling technology with new Feedmax –P

The multiple challenges of machining ISO P workpiece materials

STEP_Machinability_poster_DinA1.pdf

The Rise of Composite Materials in Aerospace Manufacturing

Challenges in stainless steel

Challenges in titanium

Challenges in cast iron

Challenges in non-ferrous materials

Challenges in hardened steel

Process optimization and sustainability

Material and machining trends in aerospace manufacturing

Engineere to make a difference

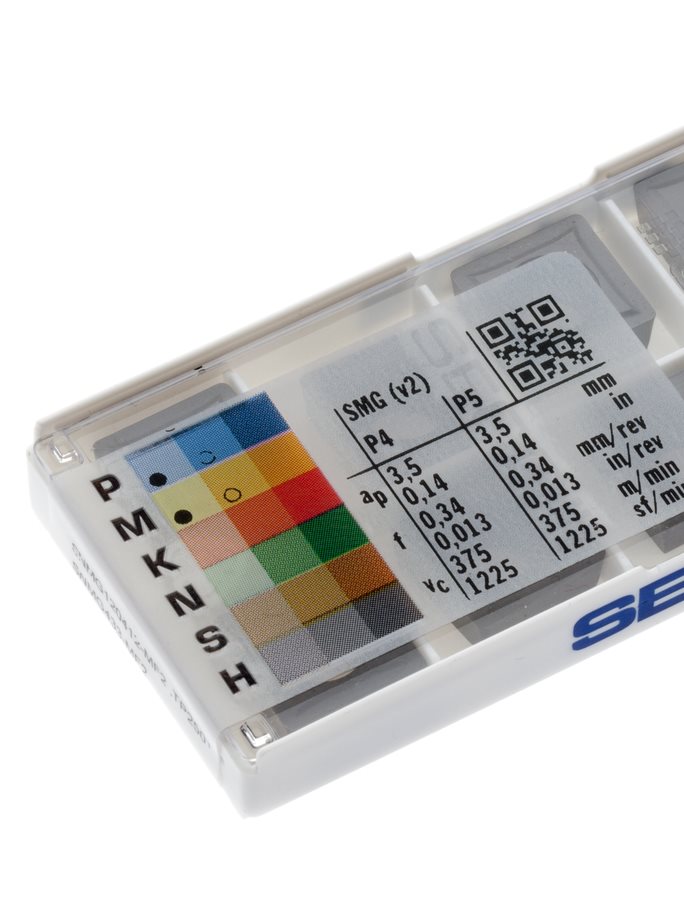

Seco Materials Group (SMG v2)

Workpiece Materials Reference Guide

Tips on how to machine Nickel-based Alloys | Seco tools

ISO Application standardization