A good day for a world record

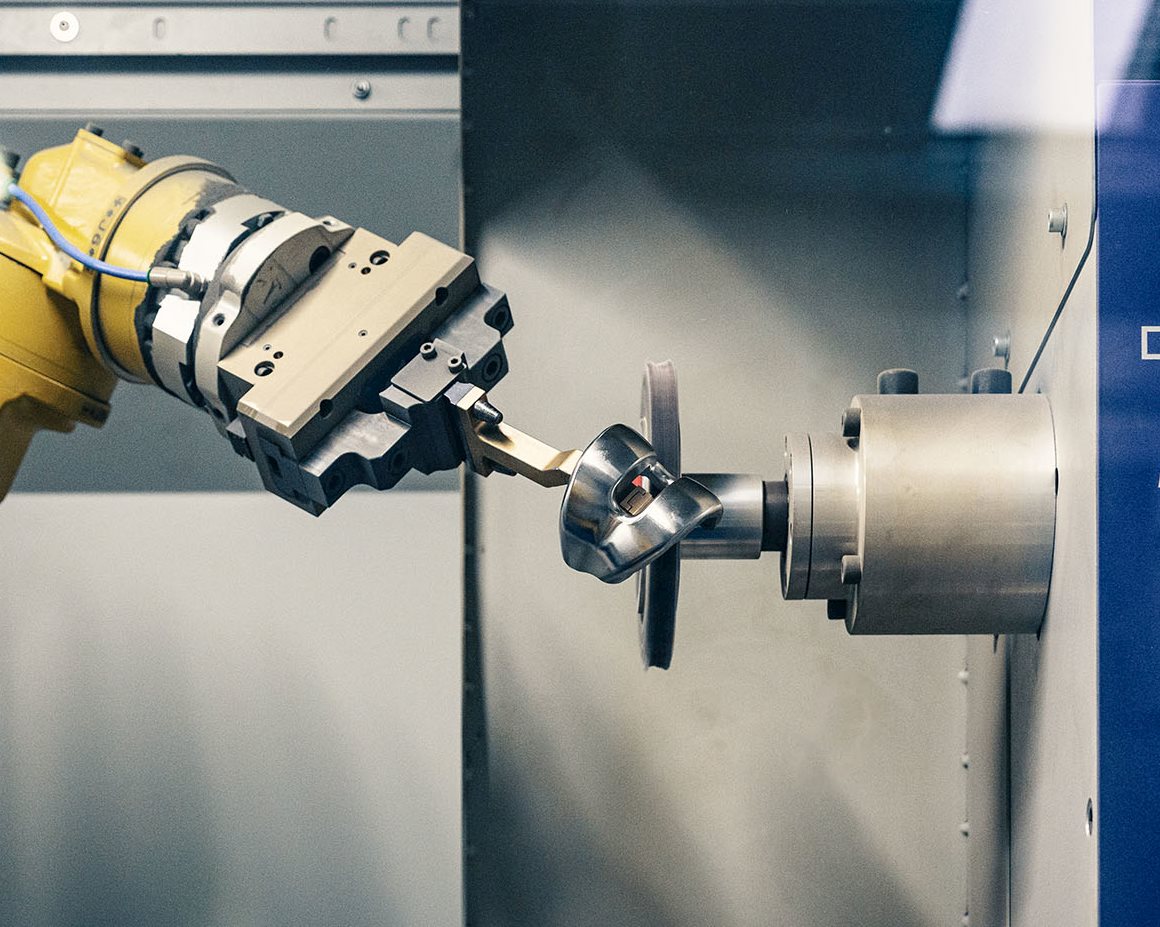

Swedish family-owned business Modig Machine Tool can call itself the fastest aerospacealuminum miller in the world after setting a new chip-removal record. The impressive achievement has already led to nearly USD 6 million (SEK 50 million) in business.“THAT WAS A GOOD DAY,” says Modig President David Modig. Modig is the third member of his family to serve as president of the company that his paternal grandfather founded with his three brothers in 1947. However, he is the first to be able to boast that he helped set a world record. In October 2017, Modig Machine Tool invited the company’s biggest customers from around the world to its factory in Virserum, Sweden, to showcase the new RigiMill processing machine. Guests watched the mill turn some 16.4 liters of solid aluminum into just over 200 liters of chips in one minute – beating the previous world record by 1.4 liters of aluminum per minute. “The faster we can cut out the details, the more competitive we become as a subcontractor – not the least to the aircraft industry which is under a great deal of pressure and needs a lot of material to be removed in its manufacturing processes,” says Modig. RigiMill has been developed in cooperation with Seco. As well as supplying the cutters for the machine, Seco also provided useful data about various levels of cutting power and different cutting speeds. “Seco has been very helpful to us in providing information that we have been able to use to design a machine that is fast and stiff enough,” says Modig.

A 2A 220-KW (295-HP) motor powers RigiMill's rotating section, the spindle. The spindle used when the record was broken has a rotational speed of up to 20,000 revolutions per minute. “But it’s not only the power of the spindle that counts; the design of the machine and the tools used are also highly significant," says Modig. "The fact that these three factors all come into play together is crucial.” The world record impressed the customers at the gathering. “The event led to SEK 50 million worth of business,” says Modig, who promises that more records will be broken by the company.

Related content

Gearing up for the win

Mutual gains for Academia and Industry

Cutting tools costs in half

Laser-assisted thermal machining: the solution for manufacturing with MMCs?

ActOn’s ‘secret weapon’ is transforming medical implants

Seco R&D delivers for Scania

Technical articles and customer success stories

GKN Aerospace continues to develop Additive Manufacturing technologies

Why a Strategic Partnership is the Perfect Medicine for Permedica

Svarvmekano is successfully adopting additive manufacturing

Škoda Auto and Seco Tools collaborate to eliminate a production bottleneck