Helical Interpolate Like A Pro

A helical or circular interpolation program is an advance milling technique for hole and pocket operations that is an alternative to drilling. Helical interpolation is a versatile method to produce a wide range of diameter holes in solid workpieces without investing in dedicated drilling tools and performing multiple tool changeovers. Tool selection, helical interpolation ramp angle and minimal hole diameter helical interpolation formula calculations are factors to be considered for reliability and accuracy.Helical or circular interpolation, also known as circular ramping, is an advanced milling technique that creates or opens an existing hole in a solid workpiece. An alternative to drilling, helical interpolation is a very reliable hole making and pocketing operation that utilizes a CNC machine to perform circular paths on the X and Y axes along with a Z axis axial feed.

While drilling operations can go to greater depths in certain applications, helical interpolation is an excellent choice for job shops where volume is not large enough to require a dedicated drill application or warrant numerous tool changeovers. A circular interpolation milling program is a fast and economical process that can produce holes on machines without sufficient horsepower and rigidity to drill into solid workpieces.

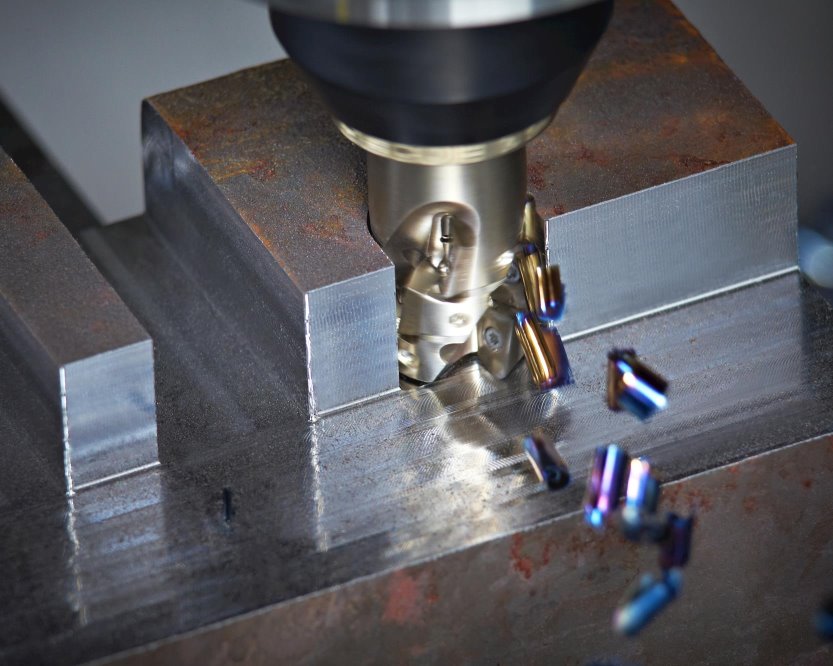

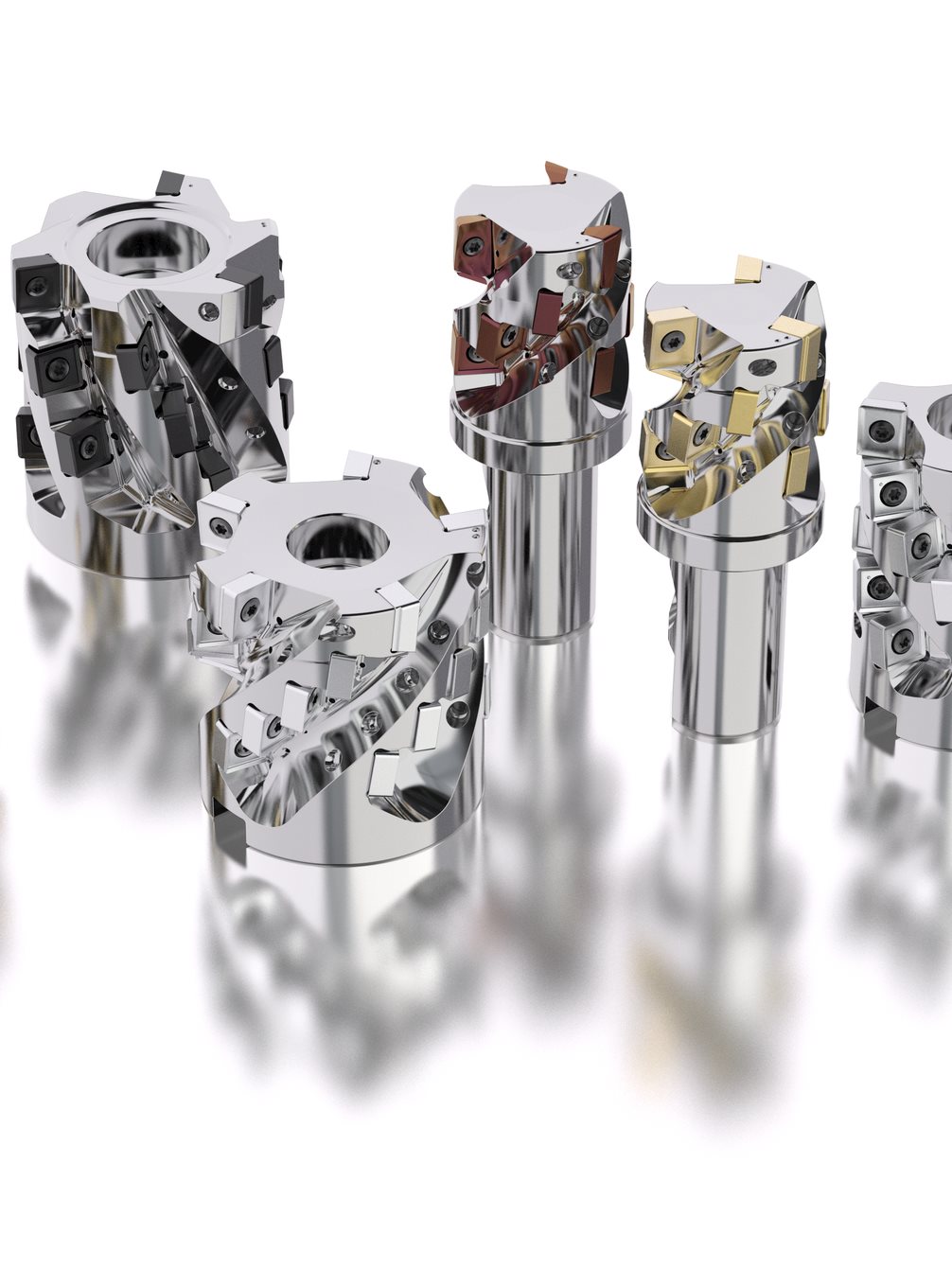

Tools that can ramp are suitable for helical milling. Solid carbide tools are capable of interpolating hole diameters of 20 mm or less, but indexable tools like Seco’s Helical Turbo 16 Milling Cutters are better for larger diameter holes and pockets that require more material removal. Choosing the correct cutter diameter when using indexable tools is important as they do not cut on-center like solid carbide tools.

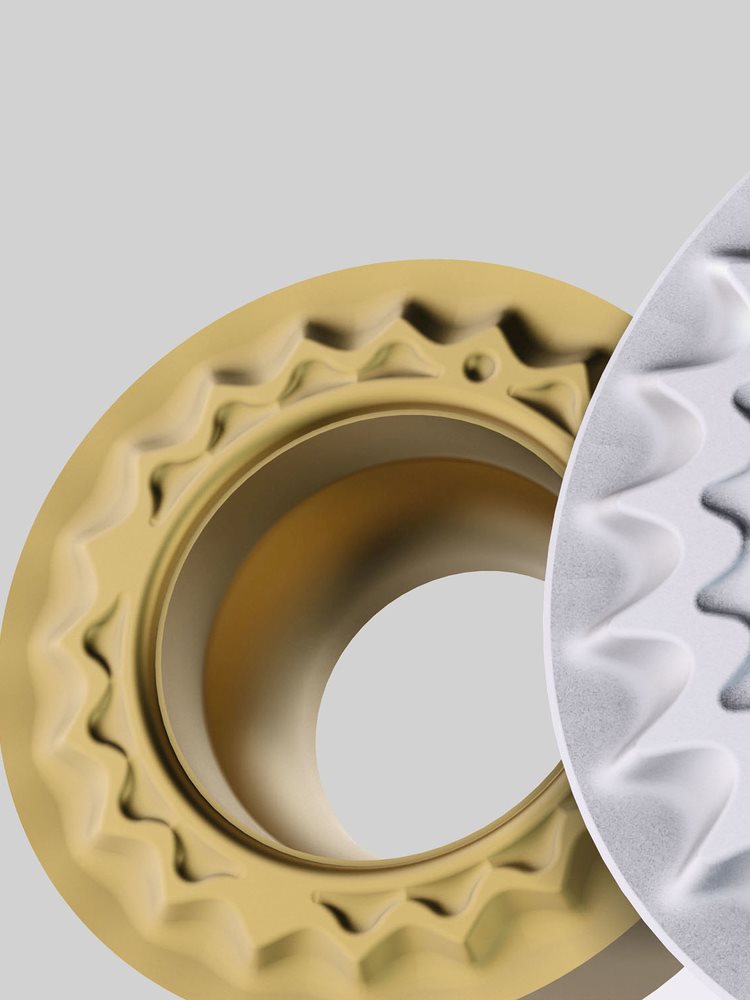

When interpolating holes and pockets into a solid workpiece, CVD-coated tools dissipate the heat generated by engaging the entirety of the tool, while PVD coatings are better suited to opening holes.

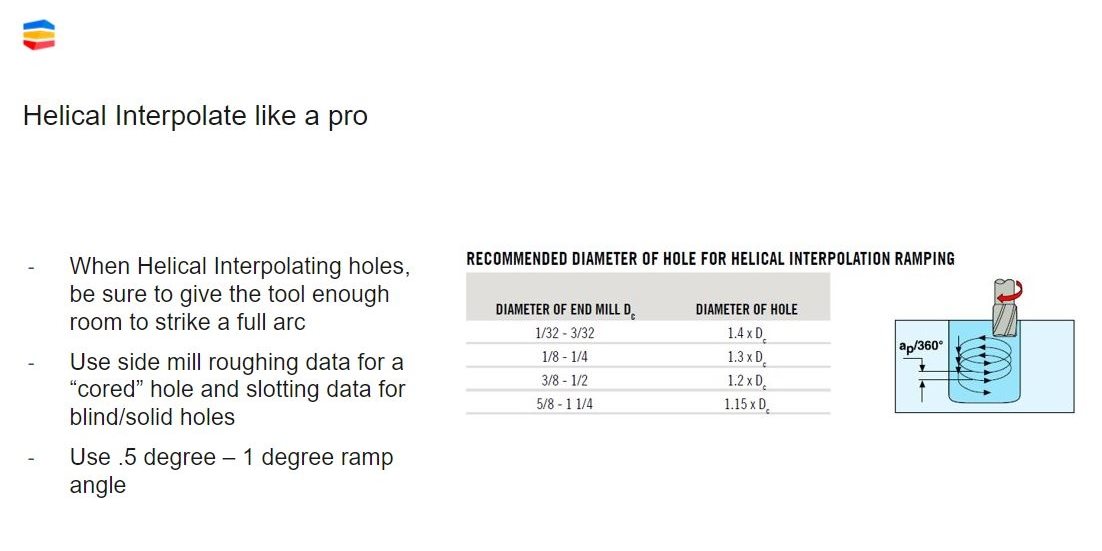

Helical interpolation ramp angles should be kept between 0.5 and 1 degree.

Chip evacuation is critical in any circular interpolation milling program. The last thing shops want to do when interpolating is recut chips. Through-spindle air blast is an excellent method of removing chips when milling steel and cast iron. Coolants are best suited for removing chips when interpolating stainless steels, high-temperature alloys and aluminum. When using coolant, however, be cautious of thermal cracking that can occur.

Hole diameter is also an important factor to consider for chip removal. Trying to interpolate a hole with an end mill diameter that is too large will not allow enough room for proper machining and chip evacuation. See the “Pro tip” below to find out how to calculate the smallest hole that a given tool can interpolate.

Pro tip: Calculate the smallest hole diameter for a given tool

In this #SecoTechTalk installment, Seco Product Manager Jay Ball provides a helical interpolation formula to calculate the smallest hole that can be interpolated for any given end mill tool. To allow the machine sufficient time to strike an arc and avoid major chip evacuation issues, multiply the end mill diameter by 30%. The result will be the smallest hole you should interpolate with that end mill. Check out Jay’s other tips that will have you interpolating like a pro.

For tips on getting the most from your machining operations, catch more episodes of Jay’s #SecoTechTalk on Seco’s Instagram. You’ll find practical advice that makes your machining more efficient and sustainable. Leave a comment to let him know what you want to hear about next.

Inline Content - Survey

Current code - 5fce8e61489f3034e74adc64

Related content

Helical Mills

The role of average chip thickness in Milling operations

What you need to know about chip formation

Is average chip thickness an outdated concept?

Seco Helical SN8-13

Seco Helical SN8-13 Milling System Delivers Performance at a Lower Cost Per Edge

Seco milling cutters reduce tooling inventory costs with versatility

FACTSHEET - Helical Turbo 16 MILLING CUTTERS

Helical Milling Cutter Comparisons on Steel (P4)

Helical Milling Cutters on Low Carbon Steel

Helical Turbo 16 Prony Screw Setup

Helical Turbo 16 Radii Indexing and Compatibility

Helical Turbo 16 Replaceable end Assembly

Helical Interpolation Application with Turbo 16

Video: Semi-Standard Helical Cutter Program Introduction

The Importance of Cutting Fluids in Metal Cutting

MF2 Chipbreaker on Round RCMT/RCGT Inserts

How to overcome chip challenges?

Video: Getting Technical - Is average chip thickness an outdated concept?

Getting Technical - Best chip formation for productivity and economy in machining