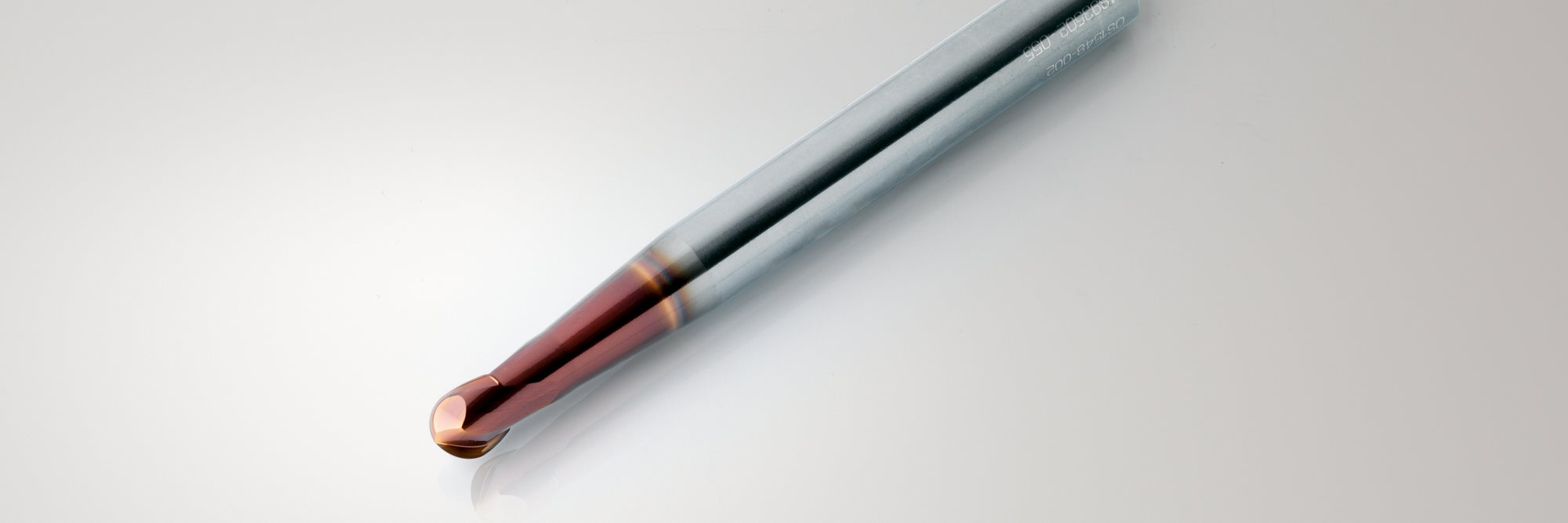

Jabro™ Solid Carbide End Mills

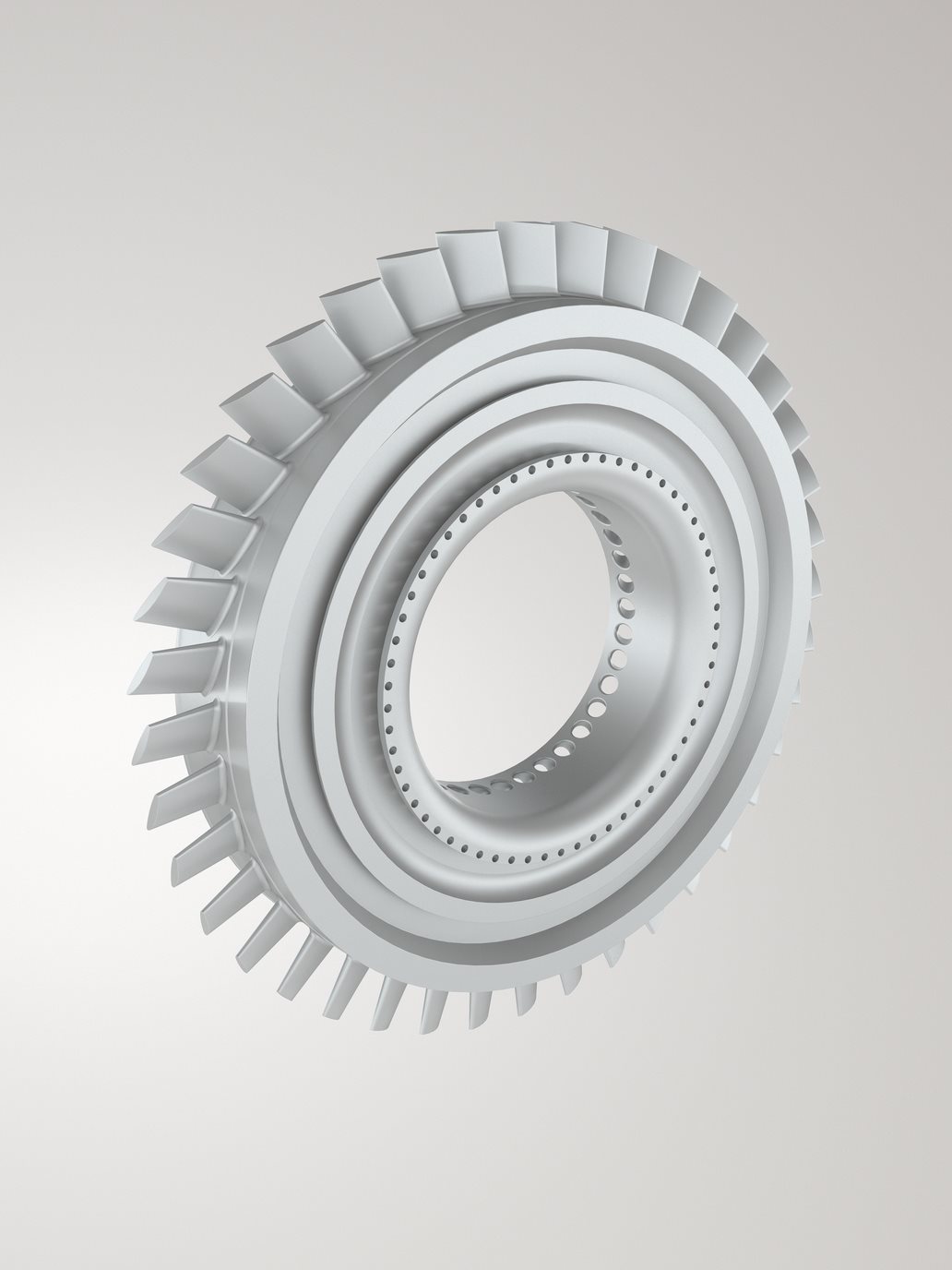

Your Challenge: Maintaining tight tolerances using complex machining strategies on airfoils, edges, hubs and fillets.Aerospace › Blisks › Jabro Solid Carbide End Mills

Your Challenge:

Maintaining tight tolerances using complex machining strategies on airfoils, edges, hubs and fillets.

Our Solution:

With differential pitch to reduce vibration and edge preparation to increase tool life, Seco’s solid carbide end mills are available in a wide range of geometries, diameters and coatings. Incorporating these cutters with strategies such as plunge milling, Z-leveling and high feed milling provides reliable, precise results. Your benefits include optimization of productivity and achieving the tolerances you need when finish machining aerofoils, leading and trailing edges, hubs and fillets.

View the product range

Related content

Video: Winning Solutions in Aerospace

Aerospace

Aerospace Blisks

Inspiration through Innovation 2020 – Aerospace Manufacturing Best-Practice Virtual Event

The new materials set to shape the future of the aerospace industry

Composite Materials: Flying High!

8 tips to machine titanium alloys

Reducing the carbon footprint in structural aerospace components

Towards a leaner and greener aviation industry

Why making an aeroplane pylon is a true collaborative process

Addressing the Aerospace Machining industries skills gap, one customer at a time

Standard Diamond Coated Drilling Solutions

Seco Profile Milling Solutions

Jetstream Tooling® with MDT

Threadmaster™ Thread Mills

Jetstream Tooling® with MDT

Seco Milling Solutions

Seco Feedmax™ Solid Carbide Drills

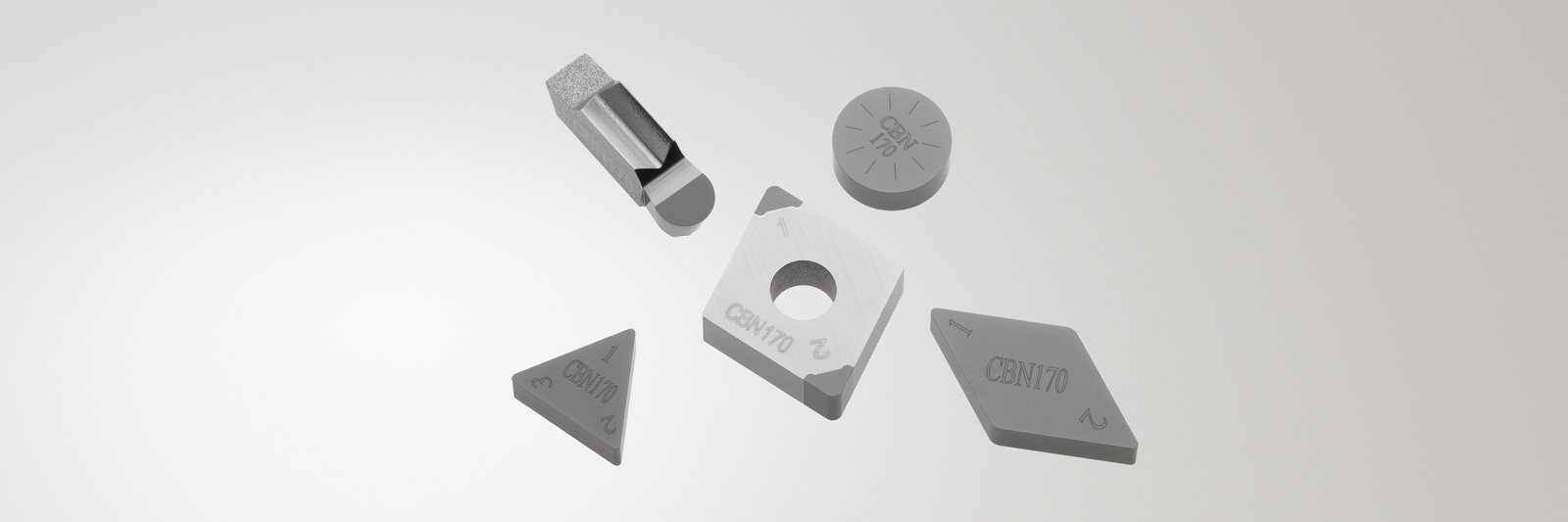

Secomax™ CBN170

Seco Jabro Solid Carbide